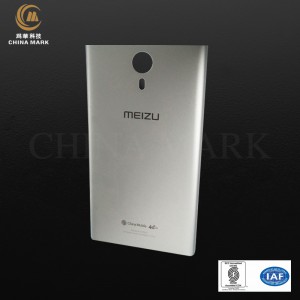

2019 China New Design China Custom Anodized Aluminum 6061/7075 CNC Machining Parts for Electric Pal

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for 2019 China New Design China Custom Anodized Aluminum 6061/7075 CNC Machining Parts for Electric Pal, First business, we learn each other. Further business, the trust is getting there. Our company always at your service at any time.

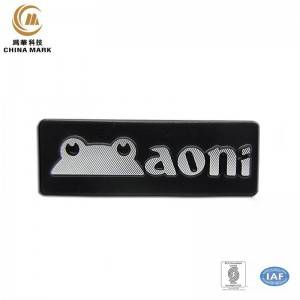

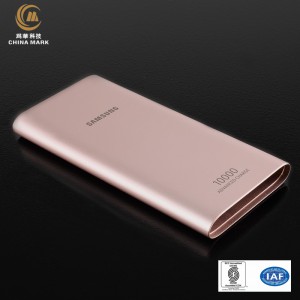

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for aluminum extrusion case, Charger Baby Housing, China Scooter Part, CNC Machining Charger Pal Parts, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

Precision CNC Machining

| Machines | Alum extrusion machine |

| Processing | - Extrusion+CNC+Anodized+finished edge. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | Phone metal housing |

| NW | 10g |

| Mold | Alum extrusion Mold |

| Mold open cycle | 8 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Precision CNC machining, please consult weihua technology — China precision CNC machining supplier;We have many years of processing experience, support customized, short time limit, timely delivery, low price!

Characteristics of CNC precision machining:

1. Reduce the number of tooling, and do not need complex tooling to process parts with complex shapes;

2. Stable processing quality, high processing precision and high repetitive precision, suitable for aircraft processing requirements;

3. High production efficiency in small batch production;

4. Can process complex surface difficult to be processed by conventional methods, and can even process some processing parts that cannot be observed;

In summary, it is the kind of structure is more complex, the product many batches and small precision parts are more suitable, such as precision shaft, optical fiber tail handle, pin, etc

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA