2019 High quality Precision Forming And Stamping - Precision Stamping Beaumont CA,Sandblasting Anodized | CHINA MARK – Weihua

2019 High quality Precision Forming And Stamping - Precision Stamping Beaumont CA,Sandblasting Anodized | CHINA MARK – Weihua Detail:

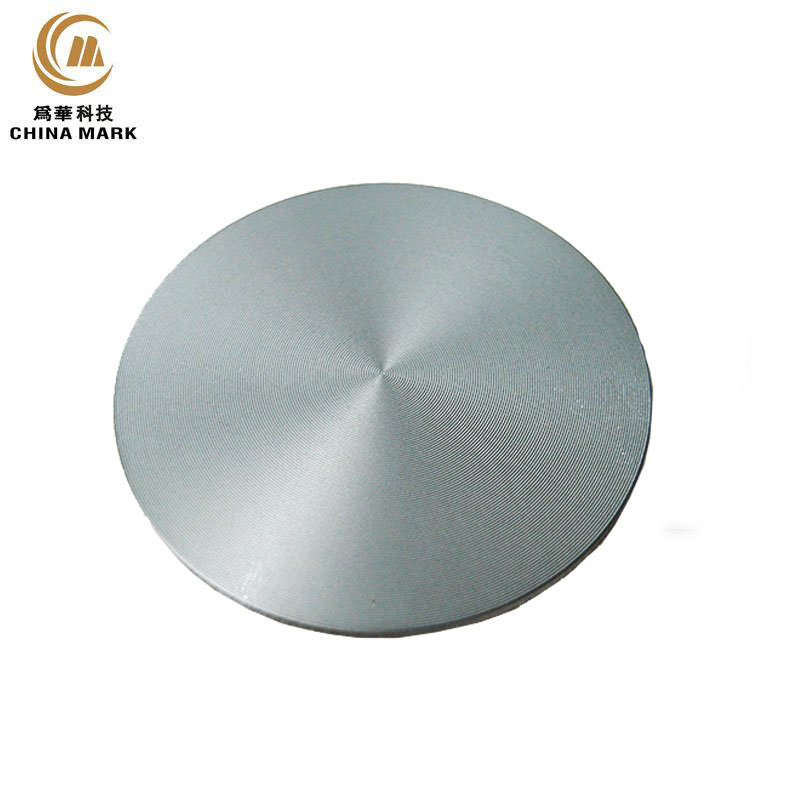

Precision Stamping Beaumont Ca

| Machines | Alum extrusion machine |

| Processing | - Alum extrusion+CNC+Sandblasting Anodized. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | VR Eye metal bracket |

| NW | 10g |

| Mold | CNC jig Mold |

| Mold open cycle | 4 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology is a professional precision stamping inc, the main precision metal stamping, stainless steel stamping parts, precision stamping parts, metal stamping parts processing, at the same time to provide customers with hardware mold integrated solution;

What are the requirements for precision stamping?

Precision stamping needs to be produced with precision punch. The structure, pressure effect and safety device of punch have the following requirements:

1. High rigidity in vertical and horizontal directions

2. the mold installation table, when installing the mold liner, the deformation is very small

3. Easy to reach the best working condition

4,.there must be measures to prevent mold damage, for precision punch, in addition to the processing center by the impact pressure, as a way to improve the processing material deformation capacity, is to make it produce hydrostatic pressure of the two auxiliary pressure generating devices.One is along the part outline design in the press plate Y ring protuberant, because the blanking cutting pressure of 50% or so is used to press on the processed material, called the tooth ring pressure plate.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for 2019 High quality Precision Forming And Stamping - Precision Stamping Beaumont CA,Sandblasting Anodized | CHINA MARK – Weihua , The product will supply to all over the world, such as: South Africa, Afghanistan, Palestine, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!