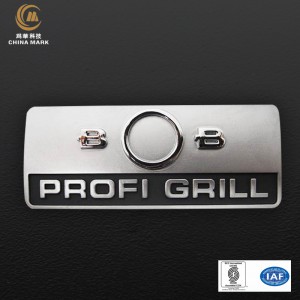

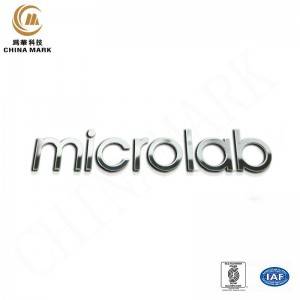

2021 High quality China Custom Order Small Qty Metal Nameplate with 3m Adhesive,Custom Sliver Metal Plate

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for 2021 High quality China Custom Order Small Qty Metal Nameplate with 3m Adhesive,Custom Sliver Metal Plate, We welcome new and previous customers from all walks of lifetime to speak to us for foreseeable future organization relationships and obtain mutual achievements!

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for China Label, Engraved Metal plate For Company, Engraved Metal Plates, Metal Engraving Logo, Metal Label, The president and all the company members would like to supply professional merchandise and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Trademark nameplate

| Type | Stamping nameplate |

| Process | Cutting+Stamping+Oil press+Blanking+Painting+Baking+High polished+Full inspection+Package |

| Application | Brand Trademark nameplate |

Design Your Custom Metal Nameplates

Aluminum name plates

Specification: 1000*2000 / 1200*2400/1200*3000/1200*4000

Thickness: 1.0mm/1.2mm/1.5mm/2.0mm/2.5mm/3mm

Features: The angular base deviation of aluminum alloy profile is less than 1 degree of positive and negative deviation.

Advantages: aluminum nameplates with good texture, slow oxidation, light texture, stylish and clean appearance, light installation, high thickness and good flatness.

Acrylic Sign

Specification: 1180*2400 / 2000*3000

Thickness: 2mm/3mm/4mm/5mm/8mm/10mm/20mm

Features: No bubbles and scratches on the surface, easy to process, the surface gloss is soft and uniform after completion, no particles, no bubbles, and even light transmission.

Advantages: Both good surface hardness and gloss, processing plasticity, can be made into various required shapes.

Stainless steel sign

Specification: 1000*2000 / 1220*2440

Thickness:2mm/4mm/5mm/6mm/8mm/12mm/14mm/16mm/18mm/20mm Features: The stainless steel plate must be pitted and welded to ensure the overall connection. After welding, all visible welds are polished smooth, as smooth as the surrounding surface, without obvious scratches.

Advantages: good texture, slow oxidation, and often use natural colors to convey a fashionable and noble temperament.

Cold rolled steel sign

Advantages: strong plasticity, easy to bend, cut, welded, polished, easy to process, strong in color adhesion, and can be used in various shapes. Silk screen process sign Film punching screen, the font and pattern strokes are clear, no distortion, and the contrast between the text color and the background color of the silk screen graphic has no obvious penetration.

Silk screen process sign

Features: Film punching screen, clear font and pattern strokes, no distortion, no obvious penetration phenomenon between the text color and the background color of the silk screen graphics.

Metal Product Nameplate Processes

Stamping

Stamping is a pressure processing method that uses a mold installed on a press to apply pressure to the material at room temperature to cause separation or plastic deformation to obtain the required parts.

Commonly used materials for stamping are: ferrous metals: ordinary carbon structural steel, high-quality carbon steel, alloy structural steel, carbon tool steel, stainless steel, electrical silicon steel, etc.

Bench drawing metal

The surface drawing process of aluminum alloy: drawing can be made into straight grain, random grain, thread, corrugated and spiral grain according to decoration needs.

Anodizing

The following oxidation coloring treatment methods are used:

1. Colored anodic oxide film Aluminum anodic oxide film is colored by adsorption of dyes.

2. 2. Spontaneous color anodic oxide film. This anodic oxide film is a kind of colored anodic oxide film spontaneously generated by the alloy itself under the action of electrolysis in a certain suitable electrolyte (usually based on organic acid). Anodized film.

3. The electrolytic coloring of the anodic oxide film is colored by metal or metal oxide electrodeposition through the gaps of the oxide film.

diamond engraving

custom aluminum nameplates diamond cutting it can maintain good compressive strength even at low temperatures, high hardness, high mechanical strength, good abrasion resistance, light specific gravity, and a relative heat index of up to 80c. It can also maintain good dimensional stability at high temperatures, fire prevention, simple process, and good gloss. It is easy to color, and the cost is lower than other thermoplastics. Typical uses are consumer electronics, toys, environmentally friendly products, car dashboards, door panels, and outdoor grilles.

Sandblasting

The application of sandblasting on the metal surface is very common. The principle is to impact accelerated abrasive particles on the metal surface to achieve rust removal, deburring, deoxidation or surface pretreatment, etc., which can change the finish of the metal surface And stress state. And some parameters that affect the sandblasting technology need to be paid attention to, such as the type of abrasive, the particle size of the abrasive, the spray distance, the spray angle and the speed.

Laser

A process of surface treatment using optical principles, which is often used on the buttons of mobile phones and electronic dictionaries.

Usually the laser engraving machine can engrave the following materials: bamboo and wood products, plexiglass, metal plate, glass, stone, crystal, Corian, paper, two-color board, alumina, leather, plastic, epoxy resin, polyester resin, Plastic sprayed metal.

screen printing

A stencil with images or patterns is attached to the screen for printing. (Suitable for flat, single-curved or curved surfaces with relatively small drop) Usually the wire mesh is made of nylon, polyester, silk or metal mesh. When the substrate is directly placed under the screen with a stencil, the screen printing ink or paint is squeezed by the squeegee through the mesh in the middle of the screen and printed on the substrate

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA