8 Years Exporter custom metal brand logo brass name plates furniture

Our solutions are broadly acknowledged and trustworthy by end users and might meet up with consistently transforming economic and social needs of 8 Years Exporter custom metal brand logo brass name plates furniture, Together with our endeavours, our products and solutions have won the trust of customers and been very salable both here and overseas.

Our solutions are broadly acknowledged and trustworthy by end users and might meet up with consistently transforming economic and social needs of , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,remember to contact us. And it’s our great pleasure if you like to have a personally meeting in our office.

Copper name plate

| Material | Usually use the Alum plate or copper under 1mm THK |

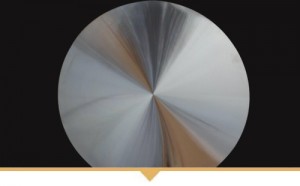

| Process | - Alum cut+forge+stamping+CD brush+anodize+oil-dripping- by stamping or cold pressing technique,- To get each kind of concentric grain effect by the hi-precision full auto CD grain machine,- To achieve each colorful part by further combining with the anodizing or galvanizing process; |

| Application | Nameplate of earphone |

| NW | 10g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

The copper nameplate provides a gorgeous look and is also durable!

Laser engraved copper nameplate

Easy to read, no scratches.We can engrave text, graphics, logos and finer precision.

UV color copper nameplate

More colorful.Immediately after UV printing, it is cured on the printer to remove stains and leave a bright, durable image.

Brass nameplate

Custom polished brass or copper signage includes custom personalization and logos – no extra charge.You can choose clean brass or copper with rich black text and graphics.

Copper nameplate, once occupied a considerable position, with the development of aluminum nameplate protection, decoration means, the application of copper nameplate has gradually declined.However, due to its strong texture, solemn tone, quaint, there is no lack of specific occasions still have applications.Signs of modern companies and businesses are specially made of copper, for example.

1. Properties of copper

Copper is a reddish metal with luster, good ductility and easy to process. Copper is stable in dry air and easily oxidized in humid environment. It is soluble in nitric acid and hot concentrated sulfuric acid, and slightly soluble in hydrochloric acid and dilute sulfuric acid.It has good thermal conductivity and etching and processing performance.

The application of copper in nameplate is mainly based on copper alloy, such as brass, which is copper-zinc alloy (zinc is less than 50%);Bronze, a copper-tin alloy (tin under 35%).

2, the coloring of copper

Previous copper plate, the main means of adornment is chrome plated, for light and corrosion protection, now it is not using copper as the main purpose of the name plate, and the true natural beauty of the nature of the action should is the use of copper and copper generated compounds of of primitive simplicity is beautiful, for other material part of nameplate, and reflects its unique style and artistic value.The classical coloring of copper and its alloys is most commonly used in the following ways.

1. Tan

Basic copper carbonate: 40~120g/L;

Temperature: 15~25℃;

Ammonia water: 200mL/L;

Time: 5~15min.

The work piece of pure copper or steel plating can be immersed in the above solution and shaken continuously. After 5min, it can turn brown and deepen continuously.Clean and dry before polishing.Polishing is the workpiece and leather edge material at the same time in the barrel of rolling mill, so that the raised part of the show the natural color of copper and concave part of the formation of a shallow deep transition tone, appear antique, elegant ancient.Apply a coat of varnish after coloring for lasting preservation.

2. The ancient black

Cook copper or copper alloy in vinegar or smoke with straw, make lampblack film is adherent, can besmear varnish again.

3. Bronze

The copper alloy will be boiled with vinegar first, and then with ammonium carbonate, sodium chloride, copper sulfate and other aqueous solution coating, after a few days will produce bronze rust.

You may also like:nameplate of camera;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:All series of alum plate

Step 2:Auto cut, by adjusting the parameters per the engineering dwg

Step 3:Neat & clean stamping workshop

Step 4:Machine the CD grain

Step 7:Professional inspectors and packaging workers

Step 5:Excellent visual effect to show the high-end level

Step 6:Auto line of anodic oxide process

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

We were completely satisfied – it was beautiful!

![]() By Renata from Malaysia – 2020.04.19 13:51

By Renata from Malaysia – 2020.04.19 13:51

The carving is well done and the price is good

![]() By Lulu from Washington – 2020.03.27 12:26

By Lulu from Washington – 2020.03.27 12:26

We were able to find what we wanted on line, service excellent, and delivery arrived much quicker than originally scheduled. All in all a very satisfactory purchase.

![]() By Kathy from Washington – 2019.12.17 10:20

By Kathy from Washington – 2019.12.17 10:20