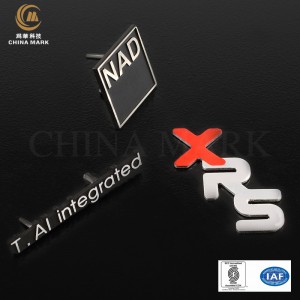

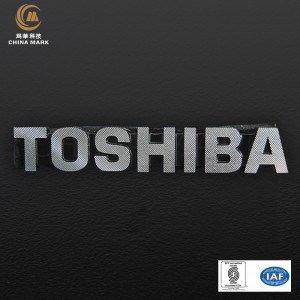

As a nameplate process, especially after etching the metal nameplate, the use of electrophoretic painting process combined, can be said to be a perfect match.

Process characteristics

Any etched nameplate, whether it is in yangwen or yin-wen, has a common feature, that is, the text and text of yangwen must have a layer of anti-corrosion protection layer to protect the text and text, and in the area outside the text and text of the metal matrix is exposed, etching into a depression;Yin wen, text, text on the contrary, text and text for the sag, exposed the matrix.On the nameplate, the exposed area of the metal matrix will be painted to achieve the purpose of protection and decoration.

In the past, the etching nameplate for coating, the process is very cumbersome, only after the use of filling or spraying to remove the excess parts of the paint layer, low efficiency, directly affect the etching nameplate process costs.

The etched nameplate is coated by electrophoresis, which is characterized by that only the parts that need to be coated, that is, the exposed parts of the metal matrix, can be deposited with the paint during the electrophoresis process, and the parts that do not need to be painted, the paint film can not be combined on the surface of the anticorrosive layer.Thus greatly simplifies the process of painting after etching.