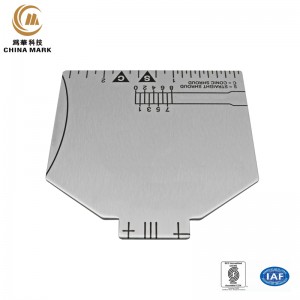

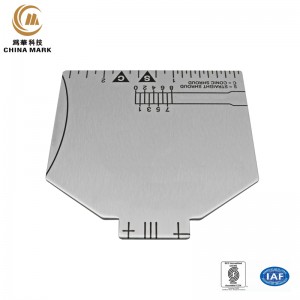

To different metal materials and even to different materials of non-metal opaque material, to make appropriate adjustments to the process, the production of different screen printing nameplates.

Features of screen printing metal nameplate:

1、Can maintain the characteristics of the metal and its surface, give the nameplate texture.

2、The nameplate has a certain mechanical strength, can be stamped forming, easy to cooperate with the machine body.

3、screen printing cycle short, simple process, low cost.

4、Can be produced on the spot, also can be printed outlets density transition layer, also can be four color screen version of the ladder color image.

Typical process flow

Metal substrate processing a graphic printing → baking → cover light → blanking a finished product

Process analytical

1、Metal bottom treatment

It is divided into conventional treatment and decorative treatment.Conventional treatment refers to polishing, brushing powder, oil removal, etc., the purpose is to provide good basic conditions for the later operation of the metal nameplate;Decorative treatment refers to the metal surface to lay the color, improve the decorative performance, such as drug white, sandblast, silk, etc.;

2、Graphic printing

The difference with the plastic membrane screen printing nameplate is that the metal nameplate is not transparent, the text is printed on the front, printed into the word;Metal surface does not absorb ink, must use metal ink or light solid ink, common ink not only adhesion is not firm, also do not have luster.

3、 baking

The use of metal ink, especially a single component of metal ink, baking temperature to reach 150℃, 20min above.This is a major point of screen printing metal nameplate.

Description of metal name plates

Material: steel, alum, copper

Process: To get every kind of wordings or graphics by way of chemical etching,

- Combining with anodizing or galvanizing way for the parts’ finish,

- Finally realize by painting or oil-dripping way,

Application: to be nameplate or Logo for any machines, for furniture or high-end equipment.

Usually, using nickel as the material, by electro-deposition way to form the graphics, further combining galvanizing or painting to get the final parts, the parts are mainly applied as the LOGO for every kind of high-end electrical appliance.