Features of the electroformed nameplate

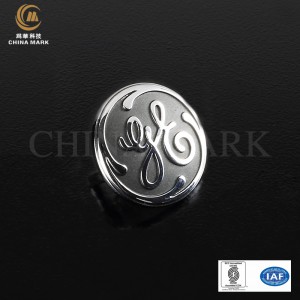

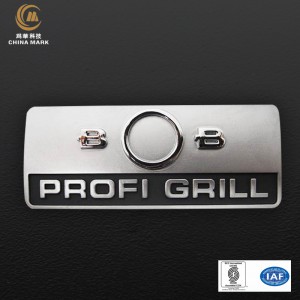

Electroforming method is used to make the nameplate, their level of fine and bright and clean degree is unparalleled in any other method, those are indistinguishable to the naked eye the fine print, as long as it can reflect on the template, in the process of electroforming deposit can also showed no difference, many current metal carriage of the watch USES electroforming nameplate paste, one of the trademarks, text of the graphic is very fine, there is a row at the bottom of the carriage is very delicate word "CHINA", the word is just 0.2 mm high, is still clearly visible.

The electroforming nameplate has a very high finish, so the finished product does not need to be processed again.

The image and text position of the electroformed nameplate, as it is deposited from the same tire mold and stripped and transferred to the viscous film, has no displacement for the discontinuous image and text.

The thickness of the electroformed nameplate is generally in the range of 0.1~0.2mm, which can be made into the complex shapes such as abnormity, cambered surface, three-dimensional, etc., for inlaying decoration. It is more suitable for the transfer and paste of the plane, so it should have the name of metal label.Its appearance is the metal bright natural color, with the different electroforming metal sediment layer trough liquid has the bright nickel (silver white) and the bright copper (golden yellow).