Aluminum extruded enclosure | WEIHUA

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:6063 round bar Ø100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Q: What is the difference between aluminum and extruded aluminum?

A: Aluminum is a kind of material, and extruded aluminum refers to extruding the material through physical pressure, and then cutting, surface treatment and other methods to make aluminum profiles of various shapes and uses. This is called extruded aluminum.

Q:How much does an aluminum extrusion die cost?

A: According to different product structures, mold costs are different. The simple ones are generally around $390~$800 , and the complicated ones have a cost of $3XX to $1XXXX of molds.

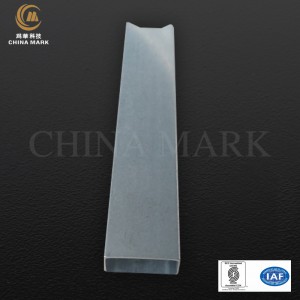

Q:How do you make aluminum enclosures?

A: Production process: raw material (aluminum rod)-aluminum rod / mold preheating-extrusion-water.cooling-slitting-stretching-slitting-framing-aging-film-fine cutting-cleaning -Full inspection-packaging

Q:Is extruded aluminum stronger than steel?

A: Steel is stronger than extruded aluminum.