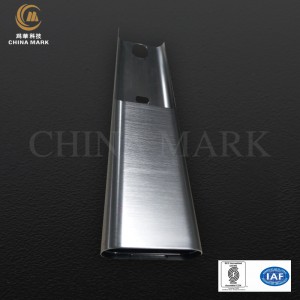

Best quality China Brushed Aluminum Outer Housing For Indoor & Outer Remote Case

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Best quality China Brushed Aluminum Outer Housing For Indoor & Outer Remote Case, With us your money in protected your business enterprise in secure . Hope we can be your trustworthy supplier in China . Searching forward for your cooperation .

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Aluminum Rear Outer Housing, OEM Best Price CNC Aluminum Extruded Outer Shell For Outer Use, We warmly welcome you to come to visit us personally. We hope to establish a long-term friendship based on equality and mutual benefit. If you want to get in touch with us, please do not hesitate to call. We will be your best choice.

Custom Aluminum Extrusion

| Description | We use high-precision aluminum extrusion extruder and high-purity 6063 aluminum rods, through customized processing of profile molds, producing various types of electronic cigarette outer cases |

| Processing | Alum bar heating machine-Raw material extrusion-Aging-Precision cutting-Full inspection-Package-Delivery |

| Application | Samsung remote control |

| NW | 16g |

| Mold | Alum extrusion mold |

| LT | 10 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Extruded aluminum enclosure customization manufacturers — weihua technology focuses on high-quality aluminum enclosures customization, aluminum shell customization, aluminum shell customization for mobile power, aluminum shell customization for mobile phones, aluminum shell customization for electronic cigarettes, etc.We provide one-stop service of die – opening extrusion fine cutting;

How to customize aluminum profiles?

1, first of all, want to order the aluminum profile, need to find can be customized aluminum profile manufacturers, this is the first thing to do, generally looking for such a manufacturer is relatively easy, we can find through the Internet, and then call for advice.Now call to consult us, more than 20 years of custom experience ~

2. After that, we need to prepare the drawings of our customized aluminum profiles, which is the most critical, because the drawings of aluminum profiles need to be given to the manufacturers of customized aluminum profiles. They need to make aluminum profiles according to our drawings.

3, after, we need to and the aluminum profile manufacturers for basic business negotiations, design to the aluminum profile die opening problem, generally the cost of the mold is often needed to our own, we need to know, unless our volume is large, the business may be free to help us open the mold.

4, then, if there is additional processing of aluminum, we also need to talk about good, processing costs are additional, we need to know this, in the process of talking about the price, also want to talk about alone, do not mix.To prevent us from paying more money.

5, after that, we need to sign the necessary commercial contract, this is very important, after all, we are the custom aluminum, after the signing of the commercial contract, the manufacturer can according to the contract production and delivery, also involved in the follow-up payment and other issues.That’s all we need to think about.

6. Finally, after each incoming material, we need to check to make sure that qualified materials can be paid to the manufacturer. If not, we need to communicate and coordinate with the manufacturer to solve the problem.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:6063 round bar Ø100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA