Cast nameplates,Etched logos,Nameplate for induction cooker | CHINA MARK

If you are interested in getting in touch with a our sales rep click here

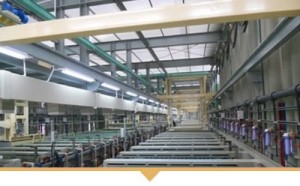

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

One–What’s tyhe characteristics of zinc alloy ?

1. Good casting performance, can die-cast precision parts with complex shapes and thin walls, with smooth casting surfaces;

2. Surface treatment: electroplating, spraying, painting, electrophoresis, polishing, water transfer, etc.;

3. No iron absorption and no corrosion during melting and die casting

4. It has good mechanical properties and wear resistance at room temperature;

5. Low melting point, easy to die-casting.

Two–What are the commonly used surface treatment processes for zinc alloy die-casting products?

1. Electrophoresis

2. PVD vacuum plating

3. Electroplating

Three– What are the advantages of the surface treatment process of zinc alloy die-casting hardware products?

1. Electrophoresis: Mainly used for stainless steel, aluminum alloy die-casting parts, zinc alloy die-casting parts, etc., can make the product show various colors, and maintain the metallic luster, at the same time enhance the surface performance, has better anti-corrosion performance,

2. PVD vacuum plating: The full name is physical vapor deposition, which can be used in various colors, such as flash silver, magic blue, crack, drop silver and other seven colors;

3. Electroplating: Electroplating is a process that uses electrolysis to attach a metal film to the surface of the metal to prevent corrosion, improve wear resistance, conductivity, reflectivity, and enhance aesthetics. It is widely used and coated High gloss, high-quality metal appearance can be obtained;

4. Painting

Products produced by fuel injection are resistant to high temperature, friction, ultraviolet, alcohol, gasoline and other products. painting can make monotonous products look more beautiful after being sprayed with various colors. At the same time, because of the additional layer of protection, it can also extend the life and service life of the product.

Four-What are the properties of zinc alloy die casting?

The mechanical properties and electroplating properties of the zinc alloy are very good. The surface roughness, strength and extensibility of the castings in the die casting plant are all very good.

Five. Which strength is better, aluminum alloy or zinc alloy?

The strength, hardness and forming function of zinc alloy are better than aluminum alloy.