Custom Metal Name Plates - OEM Manufacturer

View Our Samples

We can customize nameplates that combine different processes including stamping, printing, silk screening, embossing, engraved ,debossing, etching, sandblasting, anodizing, laser engraving, electroforming, forging, oil spraying, diamond craving, bending, CD pattern, etc. As shown in the figure below:

Oil pressure plate

Diamond craving nameplate

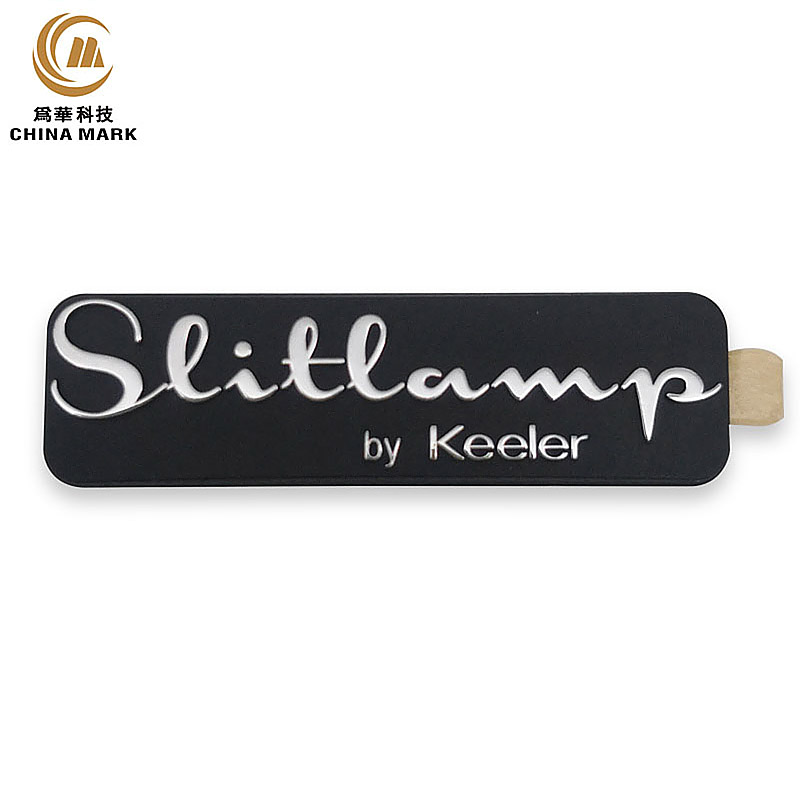

Etching nameplate

Hydraulic/forging+oxidation

Printing plate

Painting nameplate

Sandblasting tea cup accessories

olishing nameplate

Laser craving nameplate

Drawing the sign

Electroforming nickel plate

Silk screen printed nameplate

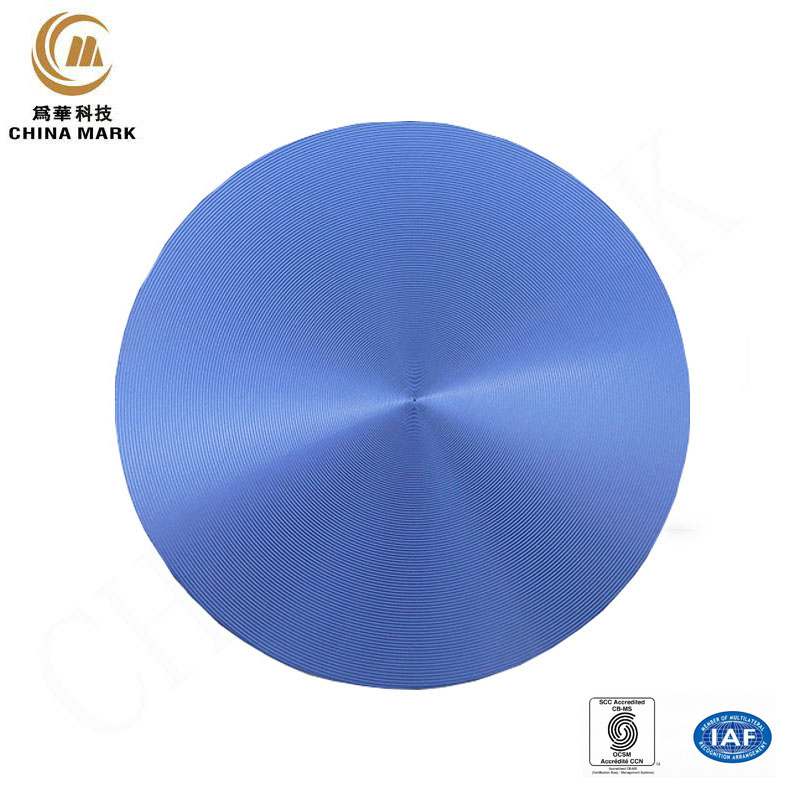

CD texture nameplate

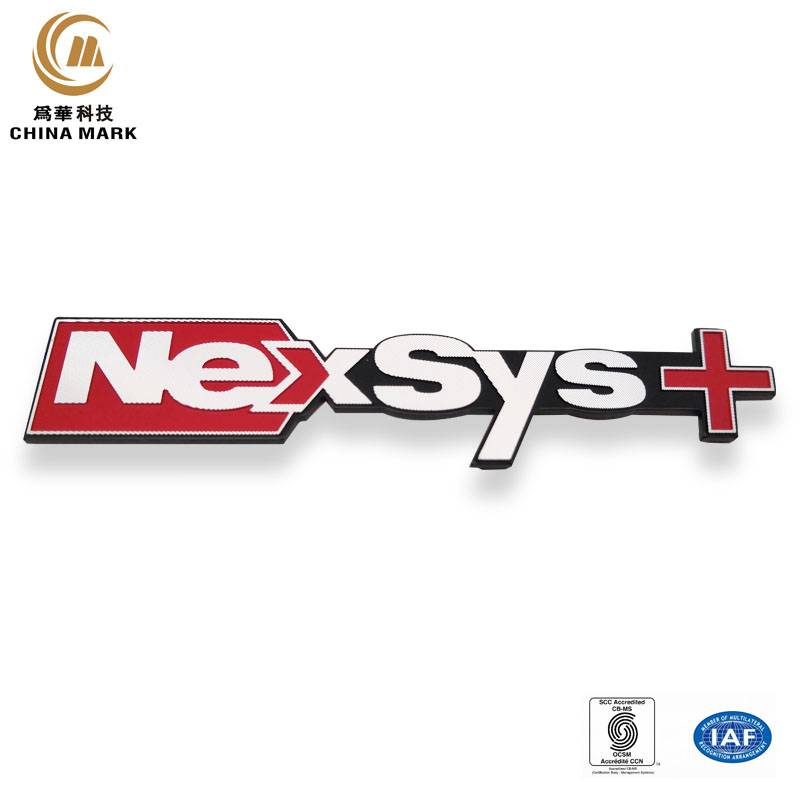

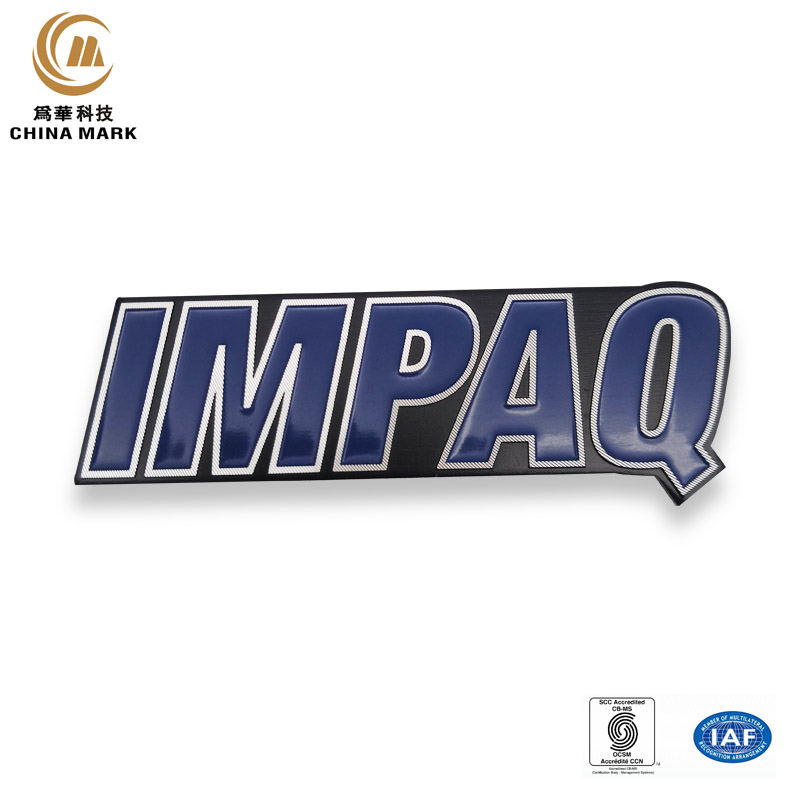

Printing + Embossing

Printing + Embossing

Printing + Embossing

Hydraulic/forging+oxidation

Printing + Embossing

Printing + Embossing

Printing + Embossing

Request a Sample – Test Our Quality Before Bulk Order

Custom Options for Metal Name Plates

In the field of custom metal nameplates, we deeply understand that each customer's needs are unique. Therefore, we have carefully created a comprehensive range of options to ensure that your ideas are perfectly realized.

We offer a rich selection. Whether it's aluminum with excellent texture, durable stainless steel, or other aluminum alloys that meet specific performance requirements, we can accurately match them according to your product characteristics and usage scenarios, ensuring that the metal name plates has excellent quality from the basic material.

CD patterns can bring exquisite texture, wire drawing process highlights simplicity and elegance, high-gloss treatment makes the nameplate bright and shiny, sandblasting endows it with a low-key matt feel, anodizing can achieve rich colors and enhance wear resistance, painting and powder coating can meet personalized color needs, while laser engraving and silk screen printing can accurately present complex patterns and texts, making the surface effect of the nameplate fully meet your expectations.

We cover various processes such as stamping, forging/hydraulic pressing, die casting, laser cutting, aluminum extrusion, and CNC. Whether the nameplate you need has a three-dimensional shape or requires precise size cutting, we can ensure that each process is accurate with advanced process equipment and a professional technical team.

We support the production of small and medium sizes, and the corners /R angles to make the nameplate feel more comfortable and avoid collision damage.

At the same time, according to your installation needs, you can choose perforated or non-perforated designs, as well as styles with or without feet, which fully fit your installation scenario.

3M adhesive stickers are easy and firm to install, while screw holes and foot fixing methods are suitable for occasions that require more stable installation, so you don't have to worry about the fixing of the nameplate.

Our nameplates are widely used in various fields such as custom metal name plates for equipment,mechanical equipment, household appliances, KTV audio, car audio, pet supplies, perfumes, and medical equipment.

Applications of Our Metal Name Plates

| Scene |

Usage description |

| Industrial equipment nameplate | metal name plates for equipment:Corrosion resistant, scratch resistant, non deformable at high temperatures, suitable for harsh environments, and suitable for long-term use |

| Audio/KTV nameplate | metal name plates for sound:Exquisite and beautiful, enhancing product grade and brand image, supporting logo customization |

| Pet nameplate/dog tag | metal name plates for pets:Wear resistant and non fading, laser engraving is clear and long-lasting |

| Household appliance nameplate | Environmentally friendly and safe, in line with international standards, commonly used in household appliances, supporting large-scale supply |

| Perfume nameplate | Compact and exquisite, showcasing brand details and professionalism |

| Medical equipment nameplate | Scratch resistant, wear-resistant, and resistant to harsh environments without deformation, usually using precision electroplating technology |

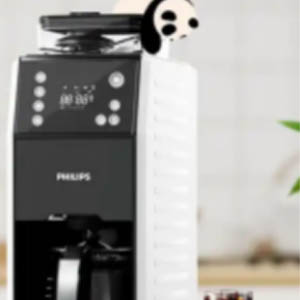

Home Appliances

Microwave Oven

Coffee maker

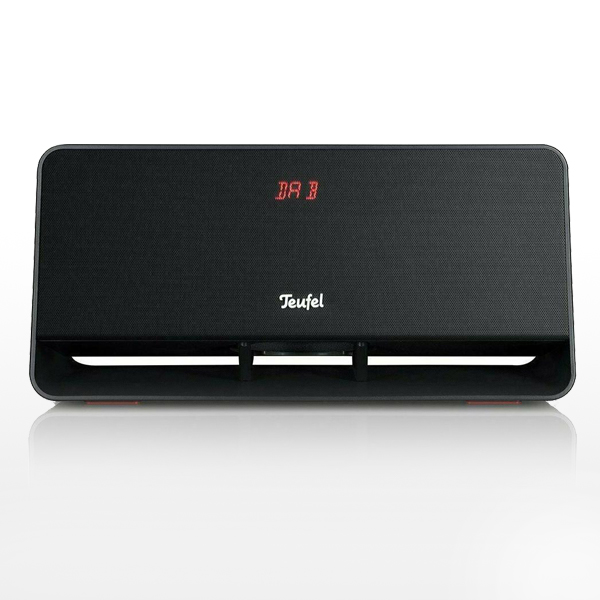

Audio

Protector

Desktop Bluetooth Speaker

Desktop Speaker

Wireless Bluetooth Speaker

Car Speaker

Car Audio

Motorcycle

Tea Tin

Tea cup

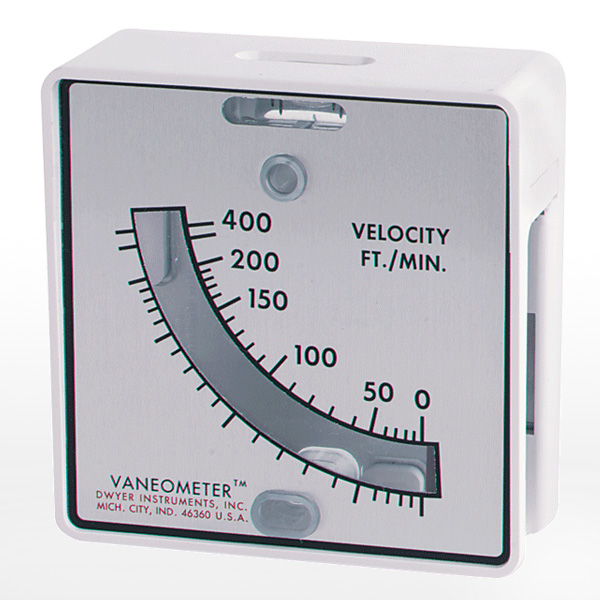

Vaneometers

Medical equipment nameplate

Audio/KTV nameplate

Household appliance nameplate

Perfume nameplate

Pet nameplate/dog tag

Industrial equipment nameplate

Your Trusted Metal Name Plate Manufacturer in China

We’re a source manufacturer with over 15 years of experience in custom production of metal nameplates. We are located in Shuikou Town, Huicheng District, Huizhou City, Guangdong Province, China, with a staff of more than 500 employee.

We have our own factory covering an area of 45,000 square meters, supporting various processes such as OEM, polishing, logo engraving, laser engraving, laser craving, oil spraying, powder coating, silk screening, CD pattern, sandblasting, and anodizing.

Our products have a wide range of applications: mainly used in mechanical equipment nameplates, audio nameplates, KTV nameplates, household appliance nameplates, pet collar logos, perfume nameplates, etc.

We also accept small batch trial orders, such as MOQ 500. The delivery date is short, usually within 7 days, and the products are exported to Europe, America, Southeast Asia and other regions. We have the right to engage in import and export trade and can provide services such as certificates of origin.

Our partners

3nod

YAMAHA

Xiaoguancha

Teufel

Philips

Panasonic

KIT

Keeler

JBL

InFocus

Harman

Dwyer

DJI

DENON

Delonghi

CAMC

BYD

Technical Insights & Knowledge Sharing on Custom Metal Nameplates

Performance advantages and applicability of metal nameplates made of different materials

When customizing metal nameplates, different materials of metal have their own advantages. The following is an introduction to four common materials: stainless steel, aluminum, brass, and zinc alloy.

1. Stainless Steel:

Stainless steel material has the characteristics of corrosion resistance, durability, and high temperature resistance. Surface treatment can be done by drawing, mirror or sandblasting. Stainless steel nameplates are suitable for outdoor needs.

2. Aluminum

The characteristics of aluminum materials are light weight, lower cost compared to other metals, excellent ductility, and the ability to undergo stamping and other processing, which can achieve large-scale production in the short term. At the same time, multiple colors can be anodized to form an oxide film layer on the surface, which is wear-resistant and does not fade, and can pass various quality tests. Suitable for lightweight nameplates such as equipment labels and electronic product identification with a large demand.

3. Brass

The color of brass material itself has a gold like effect, suitable for high-end signs such as medals and commemorative plaques.

4. Zinc Alloy

The price of zinc alloy material is lower than that of brass and stainless steel, and it can be cast with high precision and achieve complex designs in processing. At the same time, surface treatment can achieve electroplating, baking paint, sandblasting, laser engraving, etc. Zinc alloy material is suitable for 3D embossed logos and automotive nameplates.

Engraving vs Etching vs Embossing vs Printing: Best Methods for Metal Nameplates

The commonly surface treatment for making nameplates include engraving, etching, embossing, and printing, and different processes are suitable for different metal name plates requirements.

1. Engraving:

It is the use of mechanical or laser cutting to create clear content on metal materials. It has the advantages of wear resistance and corrosion resistance, and is very durable and long-lasting. Suitable for small batch customization.

2. Etching

The removal of material from a metal surface through a chemical reaction. Fine patterns can be achieved through chemical or laser etching of metals such as stainless steel and copper.

3. Embossing

Stamping through a mold to create a concave convex effect on the metal surface . One time molding, suitable for large-scale production, with extremely fast production speed and low cost.

4. Printing

There are methods such as silk screen printing and UV printing. Supports rich colors and complex patterns. Fast production speed and short delivery time. It is suitable for customers who have large-scale needs and want to get big discounts.

Carving, etching, stamping, and printing have their own advantages. When choosing any of these processes or a combination of processes to make signs, you can inform us of your intentions: for example, the quantity of your needs, your target price, your target process requirements, and the environmental temperature or factors such as wear resistance, rust resistance, and corrosion resistance that you want to meet. Feel free to contact us at any time, and we will provide you with the best production plan.

Custom Mounting & Design Options for Metal Nameplates

How to improve product assembly efficiency and service life, we provide you with professional solutions!

Do you find it difficult to choose the fixing method, edge treatment, thickness, and content information for the nameplates? Don't worry, we provide fully customized services that perfectly adapt to various usage scenarios such as industrial equipment and consumer electronics, achieving a combination of safety, durability, and easy installation!

Multiple fixed methods for you to choose from:

●Nameplates with adhesive (3M VHB adhesive) - suitable for smooth surfaces such as plastic surfaces.

● Pre-drilled nameplates - hole spacing can be customized, supporting screw/bolt fixation.

●Metal nameplates with post - convenient for assembly.

● Non-porous nameplates - suitable for welding or bonding needs.

At the same time, the edges of metal nameplates can be finely processed with deburring and rounding techniques to make the nameplates safer and more aesthetically pleasing.

The thickness of the label is usually 0.3mm~2.0mm. For harsh environments, choose thicker versions, and for lightweight requirements, choose thinner versions.

We support adding customized content such as serial numbers, your company logo, or text to enhance the traceability and brand promotion of the nameplates! Fully adapted to your needs, tailor-made to create the ideal metal nameplates for you!

Common problems and suggestions in mass customization

The removal of material from a metal surface through a chemical reaction. Fine patterns can be achieved through chemical or laser etching of metals such as stainless steel and copper.

1. What detailed information is required for quotation?

The quotation requires information such as 2D and 3D drawings, required product quantities, delivery methods, etc.

2. What is the minimum order quantity?

The regular MOQ is 500PCS, and sample orders are supported after placing the mold order.

3. How long is the delivery time?

It takes about 20 days to make molds and samples, and mass production takes 15 working days. It depends on the specific process of the product.

4. What are the packaging options available?

We can customize tray, protective films, export cartons, and export plastic pallets according to product requirements.

5. Suggestions on exports?

We can ship to Europe, Southeast Asia, the United States and other parts of the world. Support different trade methods such as EXW, FOB, DAP, etc. A certificate of origin can be provided.

6. Can the serial number of each nameplate be marked by year?

We can use mold inserts with different year numbers to achieve serial numbers for each nameplate to distinguish the year.

FAQ About Custom Metal Name Plates

1.What materials can you choose for customized nameplates?

Common materials include aluminum, stainless steel, brass, zinc alloy, etc.

2.Can the serial number be laser engraved on the nameplates?

Sure, you can use laser engraving to add a serial number to each nameplates.

3.Do you accept low minimum order quantities or trial orders?

Yes,We can accept trial orders and minimum order quantity of 500PCS.

4.How long is the production time?

Mass production about takes 15 working days. It depends on the specific process of the product.

5.Can I order labels with adhesive backing?

Sure, we accept orders for signs with adhesive backing and posts.

6.What information do I need to provide if I need to order nameplates?

The quotation requires information such as 2D and 3D drawings, required product quantities, delivery methods, etc.

7. Can you deliver the customized label to the designated location? And how to protect the label from damage during transportation?

Yes, we have customers in Japan, South Korea, Europe, America, Southeast Asia and other regions, and can deliver to designated locations according to the trade term. Customized tray or EPS can be used to avoid damage to nameplates during transportation.

8.What are the options for finish of nameplates?

Printing, engraving, coating, or anodizing can be selected based on different materials.