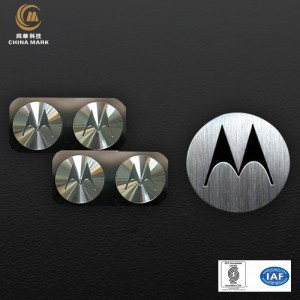

Metal etching (Metal nameplate)

The etching process is the same no matter what material is used: copper, brass, stainless steel.

After polishing the surface of the metal with a fine abrasive, hot caustic soda is used to remove the oil, and hydrochloric acid solution at room temperature is used for neutralization.On the surface after uniform polishing, coating synthetic resin type photosensitive liquid, after heating and drying, with the appropriate photographic film, close under vacuum, and uv exposure.

Use gasoline as imaging fluid to dissolve the unexposed part of the photosensitive film, so that the exposed part of the metal surface is different from the covered part.Then impregnate with ferric chloride solution, so that the exposed part of the metal surface is etched down, remove the convex part of the photosensitive film, the etching process is completed.

The etching pits can be filled with paint as needed.The surface of copper and brass can also be sprayed with a clear anti-rust paint (varnish).

Weihua technology is a professional design and production of electroforming nameplate, electroforming thin label, etching nameplate and brass nameplate engraving, aluminum printing nameplate and other metal appearance decoration enterprises.The total area is 40,000 square meters and the total number of employees is 1000.Accurate delivery, high quality, welcome to consult ~

At present, the most common metal nameplate material

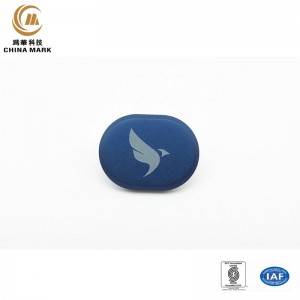

Metal logo nameplate is widely used in electronic and digital products, household appliances, leather goods, packaging gift boxes, headphones, mobile phone case, car keys, golf club nameplate, furniture and other product trademarks.

The metal nameplate production is mainly made of stainless steel, nickel, copper, iron, aluminum, zinc alloy and other materials, through stamping, die-casting, etching, electrocasting, electroplating, baking paint and other processes.

Metal nameplate production of a variety of categories, today on the common materials of a few signs briefly introduced:

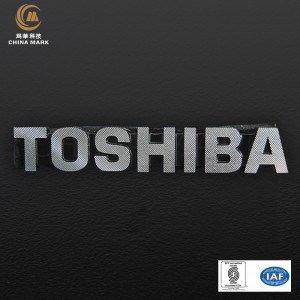

Stainless steel nameplate

Stainless steel quality nameplate, compared with aluminum material, stainless steel plate has very strong rigidity, high strength also reflected its value, and the melting point of stainless steel is very high, in the high temperature has a great advantage.

From the appearance of the nameplate, the stainless steel quality nameplate is obviously better than the gloss of zinc alloy, aluminum alloy, looks like it will be more upscale.The only disadvantage of stainless steel nameplate is that the unit price will be slightly higher than that of aluminum and zinc alloy materials, but good products with high-grade metal nameplate, the overall value will increase a lot.

Aluminum metal nameplate

The biggest advantage of aluminum nameplate is cheap price, which is a good choice for many customers pursuing low price, but aluminum nameplate is mostly used for low-end products, the overall price of the product is not too high, if the value of the product is relatively high, with aluminum nameplate will appear a little rough.

Zinc alloy nameplate

Zinc alloy nameplates are mainly used in badges, MEDALS, clothing, metal logo signs, in other aspects are not used much.

You may also like:nameplate for measuring device;Please click to view ~