Factory directly China Custom Precision Aluminum/Stainless Steel/Sheet Metal Stamping

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for Factory directly China Custom Precision Aluminum/Stainless Steel/Sheet Metal Stamping, Only for accomplish the good-quality product to satisfy customer’s demand, all of our goods have been strictly inspected before shipment.

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for China Stamping, sheet metal stamping, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We’ve been specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry might be replied as soon as possible.

Precision CNC Machining Services

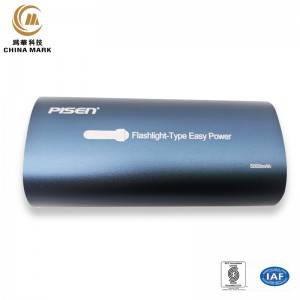

| Machines | Alum extrusion machine |

| Processing | - Alum extrusion+CNC+Sandblasting+Anodized+Laser cutting. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | Lighter |

| NW | 8g |

| Mold | Alum extrusion Mold |

| Mold open cycle | 8 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Precision CNC machining – weihua technology, the company has automatic coordinate measuring instrument, multi-axis car, grinding machine, line cutting and other advanced processing equipment, batch processing, delivery time, high precision, good finish, after-sales perfect precision CNC machining, welcome to inquire precision CNC components processing.

Which range of precision CNC machining is mainly applicable to:

Precision CNC machining is mainly applicable to machining the workpiece with complex shape, multiple procedures and high precision requirements.

1. CNC machining of box parts:

The parts with more than one hole system and more cavities are called box parts, which are widely used in the industries of machine tools, automobiles and airplanes, such as engine block, gearbox, headstock box, diesel engine block, gear pump shell, etc.

In the processing center, a clamping can complete the ordinary machine tool 60% ~ 95% of the process content;

In addition, depending on the machining center’s own precision and processing efficiency high, good stiffness and automatic tool change characteristics, as long as the development of a good process flow, the use of a reasonable special fixture and tools, can solve the box parts precision requirements higher, more complex procedures and improve production efficiency.

2. CNC machining of complex curved surface parts:

In aviation, aerospace and transportation, the parts with complex curved surface are widely used, such as CAM, aero engine integral impeller, propeller, mold cavity.

This kind of parts with complex curves, curved surfaces, or box or shell parts with no open cavity, it is difficult to achieve the predetermined machining precision by using ordinary machine tools or precision casting, and it is difficult to detect.

And the use of multi-axis linkage machining center, with automatic programming technology and special tools, can greatly improve its production efficiency and ensure the shape of the surface precision, so that the automatic machining of complex parts becomes very easy.

3. CNc machining of special-shaped parts

Irregular parts are parts with irregular shape, most of which need multi-station mixed processing of points, lines and surfaces (such as support, base, mold, etc.).When processing special-shaped parts, the more complex the shape, the higher the precision requirements, the use of processing center can show its superiority.

4, disc, cover, plate parts CNC processing

This type of workpiece includes a keyway and radial hole, end face distribution has holes, curved disc or shaft workpiece, such as the shaft sleeve with flange, and with a more porous processing plate parts, such as various motor cover.Among them, the end surface has the distribution hole system, the surface of the disk parts often use the vertical machining center, radial hole can use the horizontal machining center.

5. CNC machining of parts in trial production of new products

Precision CNC manufacturing machining center has a wide range of adaptability and high flexibility, when the replacement of the processing object, only to prepare and input new procedures to achieve processing.

Sometimes you can also modify part of the program segment or use some special instructions to achieve processing.

Such as the use of the zoom function command can be processed with the same shape but different size parts, which for single, small batch, multi-variety production, product modification and new product trial production provides great convenience, greatly shortened production preparation and trial production cycle.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA