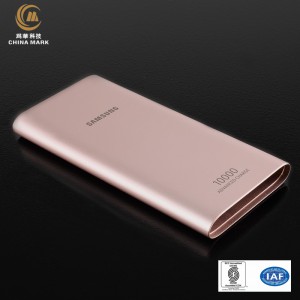

Factory Outlets Aluminum Extruded Enclosure Power Bank Housing Case Metal Housing

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for Factory Outlets Aluminum Extruded Enclosure Power Bank Housing Case Metal Housing, Along with the tenet of “faith-based, customer first”, we welcome shoppers to simply call or e-mail us for cooperation.

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for Enclosure Power Bank Housing, Enclosure Power Bank Housing Case, Power Bank Housing, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Extruded Aluminum Enclosures Electronics

| Description | We use high-precision aluminum extrusion extruder and high-purity 6063 aluminum rods, through customized processing of profile molds, producing various types of charging babies |

| Processing | Alum bar heating machine-Raw material extrusion-Aging-Precision cutting-Full inspection-Package-Delivery |

| Application | Samsung outer case |

| NW | 15g |

| Mold | Alum extrusion mold |

| LT | 10 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

The aluminum extrusion shell to find China weihua technology, more than 15 years focus on precision aluminum extrusion shell,CNC machining and other peripheral products of the production, design, processing in one of the professional high-tech manufacturers, product thread non-slip wire, tensile durability, hardness, beyond the use of standards.

As the aluminum profile manufacturers every day to squeeze a variety of different aluminum profiles, one of the shell class aluminum profile is more common, the shell class aluminum profile generally to decorative requirements are higher, some shell wall thickness is still relatively thin.Choose the right extruder, extrusion ratio to reasonable.In particular, the shell of the thin – walled aluminum extrusion force is relatively large, extrusion ratio is very important.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:6063 round bar Ø100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA