Factory wholesale Stainless Nameplate - Custom metal name plates,Brushed nickel sheet metal | CHINA MARK – Weihua

Factory wholesale Stainless Nameplate - Custom metal name plates,Brushed nickel sheet metal | CHINA MARK – Weihua Detail:

We weihua technology professionally produce all kinds of custom metal name plates, including all kinds of industrial machine signs, kitchenware signs, electrical signs, audio signs and other different materials (aluminum, stainless steel, nickel, iron, copper) signs. Our signs are made of branded high-quality materials, and the signs made are durable.

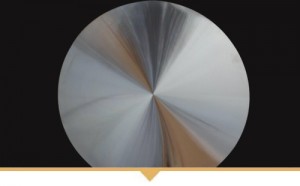

Custom metal name plates,Brushed nickel sheet metal

| Material | Usually use the Alum plate or copper under 1mm THK |

| Process | - Alum cut+stamp+CD brushed+anodized+high gloss+laser-engraving - by stamping or cold pressing technique, - To get each kind of concentric grain effect by the hi-precision full auto CD grain machine, - To achieve each colorful part by further combining with the anodizing or galvanizing process; |

| Application | Nameplate of camera |

| NW | 3g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Identification signs:

Stamped metal name plates:

Stamping is the use of molds to make various sheet-like identification signs from sheet metal on a press. This kind of forming process in cold state is called cold stamping, or stamping for short.

Anodizing signs:

aluminum and its alloys in the corresponding electrolyte and specific process conditions, due to the action of the applied current, the process of forming an oxide film on the aluminum product (anode). If anodizing is not specified, it usually refers to sulfuric acid anodizing.

Engraved Metal Name Plates:

Custom engraved metal name plates, also known as craving. Engraving graphics, patterns, fonts, etc. on metal, acrylic and other materials.

Laser engraving signs:

Laser engraving is also called laser engraving or laser marking. It is a process of surface treatment using optical principles, mainly laser engraving fonts, logos, patterns and graphics.

The FAQ:

Q1:How do i attach the plate once i receive it?

There are a couple of mounting options: adhesive or holes with screws. You may choose one that fits your applications.

If use aluminum signs on the perfume bottles, so thin but strong adhesive tape is used, which the signs will not fall off easily.

Q2:Is it possible to include a colored pattern or letter on a label?

A1:That’s a good idea. We can make it a black and white pattern or font as long as not the very complex pattern or WordArt.

A2:Yes, there are extra laser-engraved fonts on the one I bought. The fonts are very clear and the quality is guaranteed.

A3:Yes, there are 2 extra small and simple five-pointed star patterns on my logo. Although they are not in color, they are also very clear and delicate.

Q3:Can i make other colored metal nameplate ? Like orange or red ?

A1:I bought 5000 headset logos, which are beautiful and red with CD texture patterns on them. They are really good manufacturers. And delivery is fast.

A2:Mine is blue plate with letters. It was well done, nice engraving and fonts with it.

Q4:Do you have this same size that can stand on its own like a desk name plate?

A1:We currently do not have the same size signs, because all we do are custom-made signs. But we can customize your own signs according to the drawings and size specifications you provide.

A2:Yes, it is possible. I ordered 1,000 customized aluminum bending embossed signs. The signs are very shiny and without any scratches. The bending arcs on my machines are very consistent. I will repurchase them again.

Q5:What’s the price for 1 plate only?

A:Generally speaking, the price of such signs is mainly based on their process complexity and the materials and accessories used. The price of aluminum CD texture signs similar to the picture size ranges from $0.2 to $2.5. The more the quantity, the lower the price.

Q6:Can the tag be attached to a round electronic appliance?

A:Yes, we not only make round signs, we can also make rectangular logos, square signs, oval nameplates and other tags. These signs can be bent after reaching a certain size. We have multiple stamping and forging machines to make these signs bend to the angle you want.

We have a very professional engineering technology and quality team. Among them, more than 80% of the employees have at least 5 years of experience in the production of hardware signs. We have professionally produced various types of hardware signs for Hua Technology for more than 27 years. The signs produced have always been favored by customers, with a repurchase rate of 98.98%.

Our metal signs can be produced according to customer-specific design drawings or submit relevant and more optimized design schemes according to customers’ design drawings. Warmly welcome customized packaging designs required by customers, such as cartons, blister boxes, foam, film wrapping, etc. packaging requirements.

Our signs can accept shipping, air, express transportation, and EXW, FOB, CIF and other quotations.

Weihua technology (custom metal name plates engraved factory) professional processing: stamping aluminum nameplate, brass logo plate, brushed nickel sheet metal, stainless steel plate, etc.Welcome to consult ~

Laser cutting capability in metal nameplate making

Metal nameplate in the production of laser cutting is the removal of materials in the process, generally reduce the amount of processing after finishing the workpiece shape.

For example, when cutting heat-treated material, laser heat can cause hardening at the edge of the cut.Hardening can be used in many applications because it increases the durability of the product, but it also limits the amount of processing that can be done, which can be difficult after cutting threading or deburring.

Most laser cutting systems are automatically in CNC system parameters.These computer controls enable high level of precision and increase cutting speed.Some CNC programs offer “flight optics” the ability to make metal signage in the manufacture of laser-shaped material moving in the cutting head.

The laser enables fast cutting operations while maintaining precision and high efficiency in sheet metal.CNC programming can also adjust the output power so that the laser transfer sets different profiles and the thickness of the material being cut.In addition, some CNC lasers are equipped with sensory units that can adjust the distance between the cutting head and the workpiece to reduce the potential for warping.

Custom decorative metal signs as soon as possible contact us ~

You may also like:nameplate for intellectual speaker;Please click to view ~

For more details, please contact our business for understanding. Email: wh@chinamark.com.cn, WeChat/Whastapp: +86-19926691505.

people also ask:

1.Type of nameplate identification

2.How to make a metal nameplate

3.How to make metal etch nameplate

4.Daily metal logo plates maintenance and overhaul knowledge

5.What Are The Metal Signs Printing Color Difference

7.What Are The Defects That Are Easy To Produce When The Custom Metal Nameplate Is Rolled

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:All series of alum plate

Step 2:Auto cut, by adjusting the parameters per the engineering dwg

Step 3:Neat & clean stamping workshop

Step 4:Machine the CD grain

Step 7:Professional inspectors and packaging workers

Step 5:Excellent visual effect to show the high-end level

Step 6:Auto line of anodic oxide process

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

People also ask

Laser marking of metal nameplates

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Factory wholesale Stainless Nameplate - Custom metal name plates,Brushed nickel sheet metal | CHINA MARK – Weihua , The product will supply to all over the world, such as: Madras, Puerto Rico, Mombasa, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!