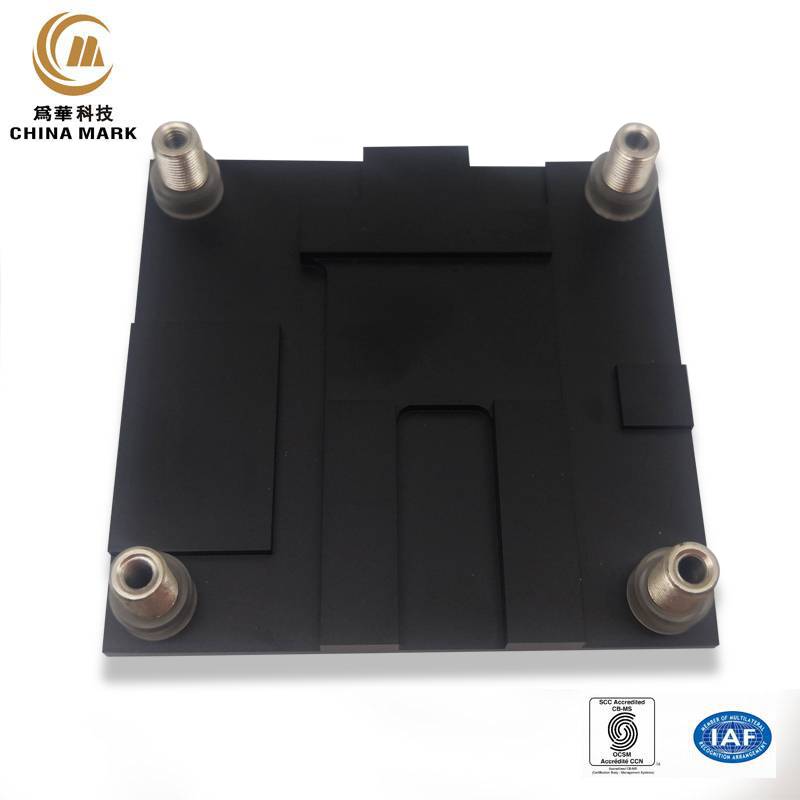

Good Quality Precision Stamping - CNC Precision,Alum Extrusion,Sandblasting Anodized | CHINA MARK – Weihua

Good Quality Precision Stamping - CNC Precision,Alum Extrusion,Sandblasting Anodized | CHINA MARK – Weihua Detail:

CNC Precision

| Machines | Alum extrusion machine |

| Processing | - Alum extrusion+CNC+Sandblasting Anodized. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | Hard shell products |

| NW | 30g |

| Mold | Alum extrusion Mold |

| Mold open cycle | 7 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology — CNC precision machining china;Engaged in precision machining CNC, precision plasma CNC and import and export parts processing customized services, mainly using CNC lathe equipment processing, if there is demand, welcome to click on the consultation.

Points for attention when CNC machining precision parts:

1. When processing CNC precision hardware parts.Require the operator to maintain the correct posture, to have enough spirit to cope with the work, the operation must be focused, no chatting, cooperate with each other, the operator must not be agitated, tired state of operation, in order to personal safety, to avoid accidents, to ensure operation safety.All employees should check whether their clothes meet the work requirements before entering the work station.Do not wear slippers, high heels and safety clothes, long hair to wear a helmet.

2. Before the mechanical action, check whether the moving part is filled with lubricating oil, then start and check whether the clutch and brake are normal, and run the machine empty for 1-3 minutes. It is strictly prohibited to operate when the machine is in trouble.

3. When starting the power to start the machine, the machine can only be started after all other personnel leave the machine work area and take away the sundries on the work table.

4. When working mechanically, do not extend your hand into the working area of the slider.In the die to take, release must use the standard tool.If the machine is found to have abnormal sound or machine failure, should immediately turn off the power switch for inspection.After the machine starts, by one person transport materials and mechanical operation, other people shall not press the electric construction or foot pedal switch board, for the safety of others more can not put the hand into the mechanical work area or touch the moving part of the machine with the hand.

5. When replacing the mold, first turn off the power, and only after the punch movement department stops operation, can the installation and debugging of the mold begin.After the installation and adjustment, the flywheel should be moved by hand to test the impact twice. In order to avoid unnecessary collision between the machine and the products to be processed, the upper and lower molds must be checked for symmetry, reasonability, firmness of screws, and reasonability of the blanking ring.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Good Quality Precision Stamping - CNC Precision,Alum Extrusion,Sandblasting Anodized | CHINA MARK – Weihua , The product will supply to all over the world, such as: Germany, Irish, Denmark, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!