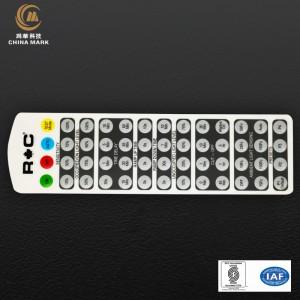

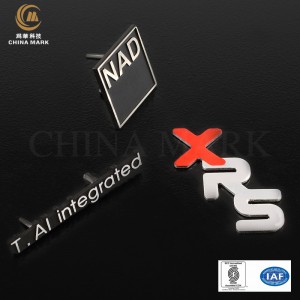

High Performance Custom Machine Nameplates brushed aluminum painting logo

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for High Performance Custom Machine Nameplates brushed aluminum painting logo, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for Factory aluminum stamping brushed painted badge, We have now more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products and solutions!

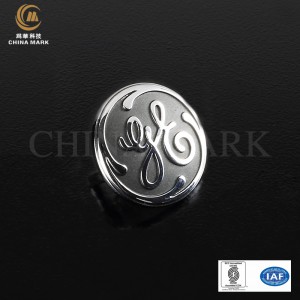

Stainless steel logo plates

| Material | steel, alum, copper |

| Process | -Alum cut+print+Ovening+Film+hole punching+stamping-To get every kind of wordings or graphics by way of chemical etching,

- Combining with anodizing or galvanizing way for the parts’ finish, - Finally realize by painting or oil-dripping way,

|

| Application | Nameplate for generator |

| NW | 13g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology (industrial nameplate inc) USES the unique process to provide metal nameplate, metal label design and processing;Widely used in electroacoustic product nameplates, brass nameplates for furniture, generator machinery and other product fields;For China sign, the choice of high quality products.Welcome to inquire ~

Standards of professional metal emblem manufacturers:

A qualified manufacturer of nameplate production products, must have the following conditions

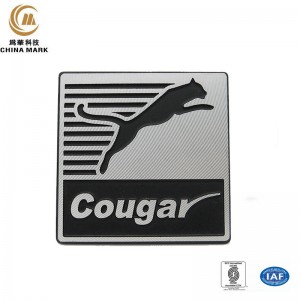

1, the proportion of appearance should be harmonious, beautiful, and as a whole scientific and economic, that is, the proportion of appearance should be easy to bear, and easy to process.

2. The color design of the signage should be harmonious, reasonable and prominent on the premise of meeting the application performance of the product.

3, in the nominal production, the pattern should have characteristics, the text should be clear and beautiful, in line with the use of people’s habits.

4, sign manufacturers sign producers should understand the processing process, which is to ensure that the product design of the desire to coincide with the possibility of processing one of the important elements.

Different processing technology can produce different decorative effect, but some complete different processing technology, also can produce the same decorative effect.This requests the designer to clearly understand each kind of craft the artistry place can produce artistic effect.

All products are out of mold consumption, demand and product size can ensure the unity of products, standards.

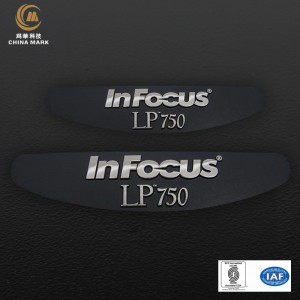

Products are through three times of cleaning, three layers of baking paint (primer, finish, varnish), are guaranteed not to decay, not fade.

From the plane to camber, outdoor to indoor and other full set of sign system, the color is rich according to the customer’s request.

Range of application: medical signs, educational institutions, office buildings, community venues, commercial areas, etc. Materials: aluminum nameplate, stainless steel nameplate, brass nameplate, steel nameplate, welcome to consult customized processing!

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA