Weihua thev naus laus zis (txhuas extrusion machining chaw) kev lag luam aluminium - aluminium profile pwm - extrusion - nto - xov, qhov kev pab cuam ib-nres, ntawv pov thawj cov lag luam; Peb tsom mus rau: CNC aluminium extrusion, complex qhov CNC ua, tsis-tus qauv CNC ua, 1 nti rau 100 nti zaub tawm ciam teb ua chaw tsim khoom, tsheb saib lub koos pij tawj saib xyuas, TV lub xov tooj ntawm tes, kev hloov kho ciam teb, txais tos rau daim duab qhia kev hloov pauv ~

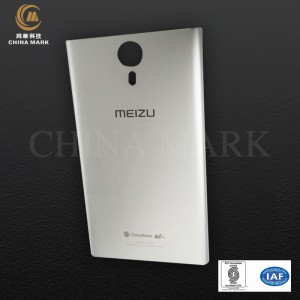

Qhov zoo ntawm txhuas lub xov tooj ntawm rooj plaub

Tsoos PC, ABS thiab lwm cov khoom siv yas tsev nyob, zoo li tsis zoo, cov khoom siv tsis tshua muaj qhov kawg, tsim qauv tsis zoo, ua rau cov cua sov tsis zoo, muaj kev tiv thaiv hluav taws xob sab hauv tsawg.Qhov tshiab lub zog ntawm cov xov tooj hlau lub xov tooj, xim zoo nkauj, zoo heev, kom kov yeej qhov shortcomings ntawm cov ntaub ntawv yas, tau dhau los ua cov khoom tseem ceeb ntawm cov khoom txawb xov tooj txawb.

Aluminium alloy plhaub yog ua los ntawm aluminium alloy cov ntaub ntawv, aluminium alloy nto tom qab oxidation xim, zoo nkauj tsos, qib siab, zoo nkauj zoo nkauj; Resistant rau av, yooj yim los ntxuav thiab huv si; Cov kev ua kom yooj yim, yooj ywm, hauv kev lag luam hluav taws xob IT hauv xov tooj txawb cov xov tooj, iPads, khoos phis tawj thiab lwm yam sib xws tau siv dav.Yog qhov zoo yog:

(1) lub ntsej muag dav, xim zoo nkauj thiab luster;

(2) xis nyob zoo, zam thiab qib zoo;

(3) coj tsis kam thiab ua tau ntev;

(4) muaj zog muaj zog, ua kom sov sai sai, tiv thaiv zoo ntawm lub Cheebtsam, tuaj yeem ua ultra-nyias;

(5) aluminium alloy yog lub teeb nyob rau hauv qhov hnyav, ductile thiab yooj yim rau cov duab, uas yog qhov zoo rau kom ntseeg tau thiab txhim kho qhov ua tau zoo ntawm cov khoom lag luam;

(6) tsis lees nrog cov av, yooj yim ntxuav.

Cov yam ntxwv thiab kev siv tau ntawm aluminium alloy ntawm lub xov tooj lub xov tooj:

5052 alloy:

Nws yog rau al-mg series antirust aluminium alloy, nrog zoo corrosion tsis kam, zoo weldability, zoo tsis kub thiab muaj zog nruab nrab.Qhov lub ntsiab alloying ntawm 5052 yog magnesium, uas tsis tuaj yeem muaj zog nyob hauv kev kho cua sov, muaj cov khoom zoo yas thiab ua haujlwm siab. hardening tus nqi.

Dav siv rau hauv kev txhim kho corrosion, weldable, nruab nrab lub zog aluminium alloy cov qauv txheej txheem; Piv txwv, nws yog siv rau cov khoom uas muaj lub siab xav tau thiab zoo weldability.Various kua thiab roj ntim thiab lwm cov khoom thauj me me ua los ntawm kev nqus sib sib zog; Kuj tseem siv nyob rau hauv cov tsheb khiav, nkoj ntawm cov nplooj ntawv hlau, cov twj paj nruag, cov cuab yeej teeb lub ntsej muag thiab cov rivet, cov khoom lag luam khoom siv, lub plhaub hluav taws xob.

6013 alloy:

Nws yog hom tshiab ntawm al-mg-si-cu aluminium alloy, feem ntau muaj cov khoom siv magnesium, silicon, tooj liab, manganese thiab lwm yam, nrog cov kev ua tau zoo.6013 yog tsim rau cov khoom lag luam nrog cov kev cai siab ntawm lub zog, tiv thaiv corrosion thiab anodic oxidation. kev ua yeeb yuj;

Cov alloy muaj ntau qhov kev siv hauv kev tsim lub xov tooj ntawm tes, aerospace, nkoj, kev thauj mus los thiab kev tsim kho cheeb tsam.Thaum siv rau cov txhuas aluminium ntawm lub xov tooj txawb plhaub, cov txheej txheem ntau lawm yog thawj cov punch tawm lub hauv paus phaj, tom qab ntawd los ntawm kev sib tsoo, sandblasting , oxidation xim lossis txheej xim, thiab thaum kawg polishing, thaum kawg tsim cov ntaub ntawv tiav hlau ntawm xov tooj ntawm tes.

6063 alloy

Nws yog rau al-mg-si series siab yas aluminium alloy.Heat kev kho mob muaj peev xwm ua kom muaj zog, zoo feem cuam tawv, tsis rhiab rau kev ceeb toom, nrog lub zog nruab nrab; Qhov ua tau zoo vuam kev ua tau zoo thiab corrosion tsis kam, tsis muaj kev ntxhov siab corrosion cracking nyiam; Zoo heev thermoplastic, siab ceev extrusion qauv ntawm cov profiles yooj yim; Kev ua kom zoo nkauj zoo nkauj, kev ua tiav zoo nkauj heev, thiab yooj yim rau anodize thiab xim.

Nws yog cov khoom siv dav siv hauv al-mg-si series, uas feem ntau siv hauv tsev cov ntaub ntawv kho kom zoo nkauj, txhuas rau cov vaj tse ntawm lub xov tooj txawb thiab khoos phis tawm, cov kav dej xau dej thiab cov khoom xa tawm rau rooj tog, platform, tsheb thiab laj kab.

6061 alloy

Nws zwm rau al-mg-si alloy, nrog cov ntsiab lus ntau dua ntawm magnesium thiab silicon ntau dua 6063 thiab ib qho me me ntawm tooj liab.Yog li ntawd, nws lub zog yog siab dua li ntawm 6063, tab sis lub quenching rhiab kuj tseem siab dua li ntawm 6063. Cua quenching tsis tuaj yeem pom tom qab extrusion, yog li nws xav tau kev kho dua tshiab thiab quenching kev laus kom tau txais lub zog siab dua.High lub zog, zoo plasticity thiab zoo heev corrosion tsis kam;

Hauv tshwj xeeb, tsis muaj kev ntxhov siab corrosion cracking tendency.Nws muaj qhov ua tau zoo weldability, corrosion tsis kam thiab txias ua haujlwm muaj peev xwm.Xav xim, yooj yim rau lub tsho, haum rau cov ntaub ntawv kho kom zoo nkauj hauv tsev thiab cov qauv ntaub ntawv dav dav.

Siv xav kom muaj qee lub zog, weldability thiab siab tsis kam rau xeb ntawm txhua yam ntawm cov txheej txheem kev lag luam, xws li qhov chaw dav hlau, qhov chaw lub koob yees duab, txuas ntxiv, nkoj ntim khoom thiab kho vajtse, khoom siv hluav taws xob thiab fittings, kho kom zoo nkauj lossis ntau yam khoom siv, hinges, lub taub hau, taub hau , tus pib nres, lub tog raj kheej, lub tog raj kheej, cov khoom siv hluav taws xob, qhov ntsuas thiab lub valve yog ib hom kev siv dav siv, cog lus rau txhua tus.

Nrog kev txhim kho ntawm cov tswv yim kev noj haus, qib siab thiab kev siv thev naus laus zis, aluminium ntawv ntim cov khoom siv ntawm lub xov tooj ntawm tes yuav tsum tau hloov kho tas li, thiab cov txhuas cov khoom siv ntawm cov xov tooj yav tom ntej zoo li yuav xav tsis thoob, ntau dua kev ua haujlwm thiab tus kheej.