Aluminium extrusion txheej txheem:

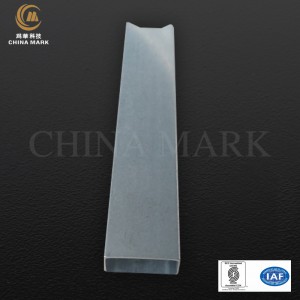

Tiag tiag extrusion pib nrog extrusion cam khwb cia nyob rau hauv txhuas pas nrig, txhuas casting pas nrig yuav tsum tau rhaub ua ntej extrusion mus muag nws, cua sov zoo txhuas casting rods sheng ingot muab tso rau hauv lub thoob extruder sab hauv, thiab tom qab ntawd tsav los ntawm high-power hydraulic extrusion pas nrig, lub pem hauv ntej kawg ntawm extrusion pas nrig muaj lub ncoo siab, xws li rhaub mos aluminium alloy hauv dummy thaiv hauv qab muaj zog los ntawm pwm precision molding extrusion, tau txais cov khoom kawg.

Aluminium bar yog qhov khoob ntawm txheej txheem txheej txheem extrusion. Aluminium bar rau extrusion tej zaum yuav khoom lossis qhov khoob, feem ntau cylindrical, thiab nws ntev yog txiav txim siab los ntawm extrusion spindles.Aluminium tuav feem ntau nrum, qee qhov yog forged lossis nias.Nws feem ntau yog tsim los ntawm sawing aluminium alloy tuav nrog zoo alloy sib xyaw.Cov pas nrig ib txwm ncu mus txog 450 degrees hauv qhov cub hluav taws xob ua ntej xa mus rau daim ntawv, nrog kwv yees li 10% nyob rau hauv cov nqaij.

Kev faib tawm ntawm cov txheej txheem extrusion:

1. Raws li cov kev taw qhia extrusion: rau pem hauv ntej extrusion, thim rov qab extrusion, sab tom qab extrusion

2. Raws li tus yam ntxwv deformation: lub dav hlau deformation extrusion axial symmetry deformation extrusion dav dav peb-seem deformation extrusion

3. Raws li lub xeev lubrication: tsis muaj lub qhov txhab lubrication extrusion lubrication extrusion zoo tagnrho lubrication extrusion

Zoo ntawm kev ua extrusion:

1. Txhim kho lub peev xwm deformation ntawm hlau

Extrusion piv ntawm txhuas ntshiab yuav ncav cuag 500, qhov sib piv extrusion ntawm ntshiab tooj liab tuaj yeem ncav cuag 400, thiab qhov sib piv extrusion ntawm hlau tuaj yeem ncav cuag 40-50.

2. Extrusion khoom muaj cov khoom lag luam siab zoo

Lub ntsej muag extrusion deformation tuaj yeem txhim kho microstructure thiab cov yam ntxwv ntawm cov khoom siv hlau, tshwj xeeb tshaj yog rau qee cov txhuas alloys nrog extrusion effect, qhov ntev ntev (kev taw qhia kev qhia) cov yam ntxwv ntawm cov khoom extruded tom qab quenching thiab kev laus dua ntau dua li cov khoom zoo sib xws tsim los ntawm lwm cov txheej txheem Cov.

3. Extrusion khoom muaj ntau yam

Kev rho tawm tsis tuaj yeem tsuas yog tsim cov yeeb nkab, pas nrig thiab xov hlau nrog cov qauv ntu yooj yim, tab sis kuj tuaj yeem tsim cov khoom seem thiab hollow nrog cov qauv ntu heev, thiab cov ntu hloov pauv nrog cov kev hloov pauv thiab maj mam hloov raws qhov ntev ntawm cov khoom seem.

Qhov sib txawv ntawm qhov ntev yog tseem dav heev, los ntawm cov tub ntxhais loj heev thiab qhov txuas nrog cov ntu nrog ib lub voj voog sab nraud ntawm 500-1000 hli mus rau qhov tsawg heev precision extrusions nrog rau tshooj loj ntawm matchsticks qhov loj me.