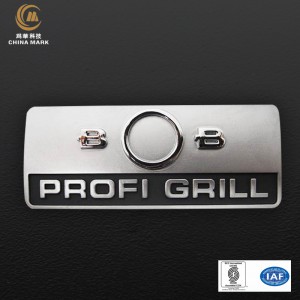

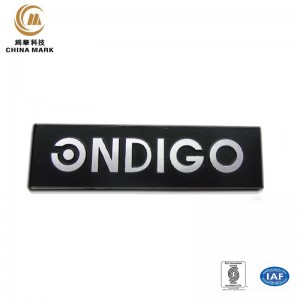

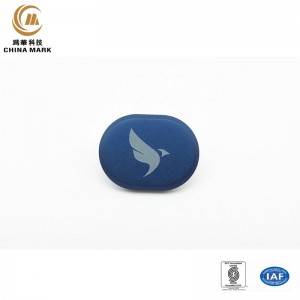

Nrum npe rau npe, Etched lub cim, Lub npe hu ua rau kev suav hluav taws xob ua khoom noj | SUAV MARK

Yog tias koj xav nyob rau hauv kov nrog peb cov muag muag rep nyem qhov no

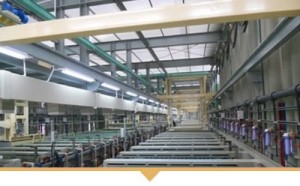

Cov txheej txheem loj muaj qhia hauv qab no

Kauj Ruam 1: Zinc alloy

Kauj ruam 2: Advanced yaj ntaus

Kauj ruam 3: Hi-precision die-cam khwb cia tooling

Kauj ruam 4: Loj teev tuag-twj

Kauj Ruam 7: Cov neeg kuaj khoom thiab cov neeg ua haujlwm ntim

Kauj Ruam 5: Galvanizing kab

Kauj Ruam 8: Cov ntu khoom

Kauj Ruam 6: Kev lag luam cub, hi temp, temp qis, qhov temp tas mus li

"Peb 40,000 square metres chaw muaj peev xwm ua tau txhua yam koj txhuas extrusion, logo daim hlau, meej stamping xav tau kev sib txuas nrog ntau ntau txoj kev xaiv kom tsim cov khoom lag luam zoo. ”

- WEIHUA

Ib qho – Dab tsi yog tyhe yam ntxwv ntawm zinc alloy?

1. Kev ua haujlwm zoo casting, tuaj yeem tuag-nrum precision qhov chaw nrog cov qauv duab thiab nyias ntsa, nrog rau cov npoo zoo du;

2. Kev kho deg: electroplating, txau, pleev xim, electrophoresis, polishing, hloov dej, thiab lwm yam;

3. Tsis muaj qhov nqus hlau thiab tsis muaj xeb thaum lub sijhawm yaj thiab tuag casting

4. Nws muaj cov cuab yeej zoo hauv lub cev thiab hnav tsis kam thaum sov;

5. Tsawg melting point, yooj yim rau tuag-tuag.

Ob – Dab tsi yog cov feem ntau siv cov txheej txheem kev kho deg rau zinc alloy tuag-casting khoom?

1. Kev Xaiv Hluav Taws Xob

2. PVD lub tshuab nqus plating

3. Kev Siv Hluav Taws Xob

Peb – Dab tsi yog qhov zoo ntawm cov txheej txheem kho saum npoo ntawm zinc alloy die-casting hardware khoom?

1. Electrophoresis: Feem ntau siv rau stainless hlau, aluminium alloy tuag-casting qhov chaw, zinc alloy tuag-casting qhov chaw, thiab lwm yam, tuaj yeem ua rau cov khoom lag luam qhia ntau yam xim, thiab tswj cov lus hlau, tib lub sijhawm txhim kho nto, muaj kev ua tau zoo los tiv thaiv corrosion,

2. PVD nqus plating plav: Lub npe tag nrho yog lub cev vapor deposition, tuaj yeem siv ntau yam xim, xws li flash nyiaj, khawv koob xiav, tawg, poob nyiaj thiab lwm yam xim xya;

3. Kev Siv Hluav Taws Xob: Kev siv lub tshuab hluav taws xob yog txheej txheem uas siv electrolysis los txuas cov yeeb yaj kiab hlau rau saum npoo ntawm hlau kom tiv thaiv xeb, txhim kho kev hnav, kev coj tus cwj pwm, kev cuam tshuam, thiab txhim kho qhov zoo nkauj. Nws yog dav siv thiab coated High gloss, zoo hlau muaj peev xwm tau txais;

4. Xim duab

Cov khoom tsim los ntawm kev txhaj tshuaj roj muaj peev xwm tiv taus kub, txhuam, ultraviolet, cawv, roj av thiab lwm yam khoom. cov xim pleev xim tuaj yeem ua rau cov khoom siv monotonous zoo nkauj dua tom qab raug txau nrog ntau xim. Tib lub sijhawm, vim tias muaj cov txheej tiv thaiv ntxiv, nws tuaj yeem txuas ntxiv lub neej thiab kev pab lub neej ntawm qhov khoom.

Plaub-Cov khoom ntawm zinc alloy tuag casting yog dab tsi?

Cov khoom siv kho tshuab thiab cov cuab yeej hluav taws xob ntawm cov zinc alloy yog qhov zoo heev. Qhov saum npoo roughness, lub zog thiab extensibility ntawm cov ua nyob rau hauv qhov tuag casting cog yog txhua yam zoo.

Tsib. Lub zog twg zoo dua, aluminium alloy lossis zinc alloy?

Lub zog, ua kom tawv thiab tsim kev ua haujlwm ntawm zinc alloy yog qhov zoo dua li aluminium alloy.