Hot Selling for China Custom Precision CNC Parts of Machined/Machining/Machinery Processing with Material of Metal/Aluminum Alloy/Stainless Steel

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for Hot Selling for China Custom Precision CNC Parts of Machined/Machining/Machinery Processing with Material of Metal/Aluminum Alloy/Stainless Steel, To offer prospects with great equipment and solutions, and frequently develop new machine is our company’s business objectives. We glance ahead for your cooperation.

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for China CNC Machinng Services, CNC Machining Item, Custom CNC Machining, Machined Parts, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our solutions have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

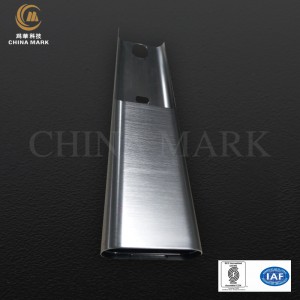

Precision NC Components

| Machines | Alum extrusion machine |

| Processing | - Alum+Late+Anodized. - further combined with polishing/sand-blasting/grained to be the finish- to get the protective layer by anodic oxide coating- to get the logo by laser-engraving |

| Application | Baidu clouds Decorative ring |

| NW | 26g |

| Mold | Alum extrusion |

| Mold open cycle | 8 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua — precision forging and stamping pvt.ltd.Committed to CNC precision processing, mainly providing medical parts processing, communications parts processing, photoelectric parts processing, auto parts processing, CNC precision processing, CNC processing, complex parts CNC processing, non-standard parts CNC processing;Processing accuracy up to 0.01m, welcome to contact to negotiate!

The importance of heat treatment for precision metal processing

Precision metal processing in the common processing technology has a lot of, such as: forging, heat treatment, surface treatment, these processes are in order to make the precision parts more practical.

Heat treatment includes three stages: heating, insulation and cooling.The main factors at work in heat treatment are temperature and time.

Heat treatment is to heat the steel in the solid state to a certain temperature, for the necessary insulation, and at an appropriate rate of cooling to room temperature, in order to change the internal structure of the steel, so as to obtain the desired performance.

In the precision hardware processing, the heat treatment is to improve the mechanical function of the mechanical parts, to ensure that the processing quality meets the use needs of the goods.

The importance of precision metal processing heat treatment is as follows:

1. The purpose is to change the internal structure of the steel to improve the performance of the steel.

2. Proper heat treatment can significantly improve the mechanical properties of steel and prolong the service life of machine parts.

3. The heat treatment process can not only strengthen the metal materials to fully tap the potential of material properties, reduce the structural weight, save materials and energy, but also improve the quality of mechanical products, significantly extend the service life of machine parts.

4. Proper heat treatment process can eliminate all kinds of defects caused by casting, forging, welding and other hot processing processes, refine grain, eliminate segregation, reduce internal stress, and make the steel structure and performance more uniform.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Alum extrusion machine

Step B:Auto-lathing machine

Step C:CNC machine

Step D:Auto sand-blasting machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Laser-engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA