WEIHUA - ụlọ ọrụ na-ahụ maka mkpuchi mkpuchi, ọkachamara na nhazi PVD, plating, PVD mkpuchi mkpuchi mkpuchi mkpuchi, dị ka titanium nitride mkpuchi mkpuchi mkpuchi nwere oke ike, nguzogide okpomọkụ dị elu, mmebi mmebi, titanium nitride, nano mkpuchi emeputa, mkpuchi mejupụtara, ebu titanium plating, mkpuchi PVD nke nhazi mkpuchi titanium, ihe karịrị afọ 10 nke ụlọ ọrụ nwere ọmarịcha ọrụ, ụlọ ọrụ ahụ na-ewebata akụrụngwa mkpuchi PVD na ngwa nhazi ihe nkedo plasma dị na ya, ịrụ ọrụ mara mma, ịnabata ịjụ ase!

Ugboro ole PVD nano coatings dị? Kedu uru ya?

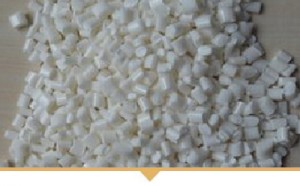

Ihe mkpuchi PVD

Njirimara nke ọgwụgwọ igwe dị elu PVD mkpuchi: mee ka ndụ dịkwuo elu, nwekwuo ike, nwekwuo uru, na ịdị ike ya dị elu, nguzogide akwa akwa, nguzogide nrụrụ siri ike, nguzogide okpomọkụ dị elu, nguzogide adhesion na arụmọrụ ndị ọzọ dị elu na-ejikarị eme ihe na ụlọ ọrụ ebu.

PVD bụ English Physical Alụlụlụ Deposition (PVD), na-ezo aka n'okpuru ọnọdụ nke agụụ, na ala voltaji, elu ugbu a aus ihapu technology, ojiji nke gas orùrù maka agụụ mkpuchi akụrụngwa nke mere na titanium efere evaporation na evaporate okwu na gas ionization, eji electric ubi osooso, ime ka evaporation ihe onwunwe na mmeghachi omume ngwaahịa Deposition na workpiece.

A na-akpọkarị mkpuchi PVD: ọgwụgwọ elu igwe, mkpuchi, ihe nkedo titanium, mkpuchi agụụ, ihe mkpuchi chromium, nhazi nke titanium, PVD, ọgwụgwọ elu, efere titanium, ọgwụgwọ elu, nhazi mkpuchi mkpuchi, ọgwụgwọ elu, wdg.

1. Elu nke nkenke na-ebu ebu nwere ike ịnwe oke esemokwu mgbe etinyere ya na mkpuchi agụụ, nke nwere ike belata nhazi ọrụ ahụ. Mgbe etinyere ebu ahụ na mkpuchi agụụ, enwere ike ịgbatị ike ahụ site na 5 ruo 10 ugboro, na abrasion elu nwere ike belata nke ukwuu.

Mgbe oyi blanking na ịbịaru anwụ na-ntekwasa na agụụ mkpuchi, esemokwu nwere ike budata belata, na ọkọ na abrasion nwere ike budata belata .Ya mere, ọ nwere ike dịkwuo ndụ mmadụ na-ebelata na-eri budata.

Uru:

Belata esemokwu ọnụọgụ, belata igwe ọrụ

Mee ka isi ike dịkwuo elu, gbasaa ndụ nke ebu ahụ

Gbochie ntutu ntutu ngwaahịa, dọpụta, melite ogo ngwaahịa

Zọpụta nsogbu nke ibudata ebu, na-eme ka ọ dị ọcha ma na-ebugharị ngwa ngwa, meziwanye arụmọrụ

2, ihe nkedo plastik n'ihi nhazi ya dị mgbagwoju anya na-ekpebi nsogbu nhazi, yabụ ọnụahịa dịtụ elu, yabụ iji melite ndụ nke ebu bụ isi okwu, ọkachasị enyo na elu etching, ọ dị mfe iyi, nke abụwo ihe na-egbu mgbu nke ukwuu.

Ihe siri ike nke mkpuchi plastik na-ekpuchi na agụụ na-abawanye, na nkwụsị abrasion mụbara n'ụzọ dị ukwuu. Ma n'ihi mmelite nke ngwụcha elu na mbelata nke esemokwu nke ebu, ihe ngwongwo plastik dị mma na ngwaahịa plastik bụ mfe iji wepụ ebu.

N'otu oge ahụ, n'ihi usoro ọrụ ya pụrụ iche, mkpuchi agụụ na-etolite akwa nchekwa dị n'elu nke ebu ahụ, nke nwere ike idozi nsogbu nke mmebi ahụ. Nke kachasị mkpa, n'ihi na mkpuchi anyị agaghị agbanwe ọnọdụ elu nke ebu ma ọlị, ma ọ bụ enyo ma ọ bụ etched elu, ọbụna ihe ndị dị oke mkpa nke CD ebu

Uru:

Eyi eguzogide dị elu, ebu ndụ ukwuu ịgbatị

Oge ihe na-agbapụta nke ihe roba dị ogologo na mmetụta ndozi ka mma

A na-eme ka ihe dị elu nke ngwaahịa plastik dịkwuo mma ma na-ebelata ntụpọ ntụpọ

Demoulding dị mfe, ọbụna zere iji demoulding gị n'ụlọnga

Ọma gbochie corrosive ihe onwunwe si corroding ebu matriks

Ebu dị mfe ihicha ma nhicha nhicha dị ogologo

3. The agụụ mkpuchi nke electronic ụlọ ọrụ na-abụghị nanị etinyere na mma ebu nke ngwaike na plastic igwe ụlọ ọrụ, kamakwa ukwuu mfọn ke electronic ụlọ ọrụ ruru ya elu elu ekweghị ekwe, mma imecha na elu nkenke.

Ọmụmaatụ, ọnụ agụba, IC nkwakọ ịnwụ, PCB nhazi nke Micro-egwe ọka Micro-mkpọpu ala, PCB oghere zọ anwụ, goldfinger anwụ, wdg, mkpuchi na ngwaahịa ndị a abụghị naanị dozie ọtụtụ nsogbu nke ndị ọrụ, kamakwa wetara ha ọtụtụ uru.

Uru:

Okpukpo mkpuchi dị ezigbo mkpa, nke nwere ike izute ihe achọrọ nke nkenke dị elu na ụlọ ọrụ eletrọniki na ọ bụ ezigbo gburugburu ebe obibi. Ọ nwere ike ịchọta ụdị nchekwa dị iche iche (dịka ntụziaka RoHS) iji melite nkwụsị nke ngwa ọrụ ma ọ bụ akụkụ ma hụ na nkwụsi ike nke mma ngwaahịa.