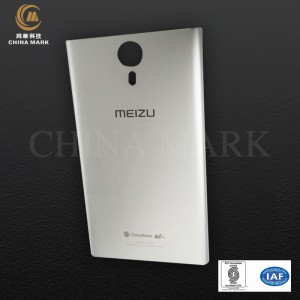

Low MOQ for China Glass PVD Vacuum Coating Machine/Glassware Vacuum Metallizing Case

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Low MOQ for China Glass PVD Vacuum Coating Machine/Glassware Vacuum Metallizing Case, Now we’ve set up steady and long small business interactions with consumers from North America, Western Europe, Africa, South America, far more than 60 countries and regions.

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for China Glass Vacuum Coating Machine, Glassware PVD Vacuum Metallizing Machine Case, We have been looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

PVD plated,Decorative electro coatings

| Material | ABS |

| Process | -Material prepare+moulding+deburr+grinding+galvanizing+ovening |

| Application | Remote control car |

| NW | 15g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

The decorative PVD coating sets the product apart.In addition to protection from scratches and wear, the attractive color on the metal’s exterior enhances the value and service life of many goods.

Decorative PVD plating advantages:

1. High hardness

2. Impact resistance and scratch resistance

3. Wear resistance

4, chemical inertia/no rust

5, tasteless

6. Prevent allergies

7. Metal appearance

8. Customize the color

9. Uniform color

10. Applicable materials: stainless steel, titanium alloy, aluminum alloy, brass, zinc alloy, ABS plastic

Characteristics of PVD coated film

PVD coating technology is used to plating the film layer, with high hardness, high wear resistance (low friction coefficient), good corrosion resistance and chemical stability, the film life is longer;At the same time, the film layer can greatly improve the decorative performance of the workpiece.

PVD coating technology is mainly divided into two categories: decorative coating and tool coating.

The purpose of decorative plating is mainly to improve the appearance of the workpiece decorative performance and color at the same time to make the workpiece more wear-resisting corrosion resistance to extend its service life;This respect basically applies each domain of hardware industry, be like door window hardware, lock, wei yu hardware to wait for an industry.

The purpose of tool coating is mainly to improve the surface hardness and wear resistance of the workpiece, reduce the friction coefficient of the surface, and improve the service life of the workpiece;This aspect is mainly used in a variety of cutting tools, turning tools (such as turning tool, planer cutter, milling cutter, drill bit, etc.), various hardware tools (such as screwdriver, pliers, etc.), a variety of molds and other products.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

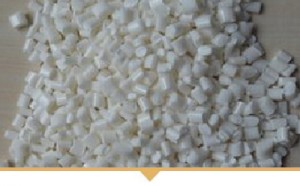

Step 1:ABS resin

Step 2:Molding machine

Step 3:Hi-precision tooling

Step 4:Galvanizing line

Step 7:Accessory for splendid toy

Step 5:Industry oven

Step 6:Full check lines

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA