Manufacturing Companies for China Polypropylene PVC Plastic Sheets Fiber PETG Plastic Sheets

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Manufacturing Companies for China Polypropylene PVC Plastic Sheets Fiber PETG Plastic Sheets, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Building Material, China PVC Plate, PC logo plate, If any item be of interest for you, make sure you let us know. We’ll try our best to satisfy your requirements with high quality merchandise, the best prices and prompt delivery. Please feel free to contact us at any time. We are going to reply you when we receive your inquiries. You should note that samples are available before we start our business.

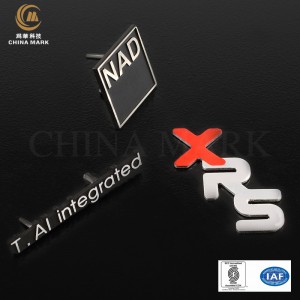

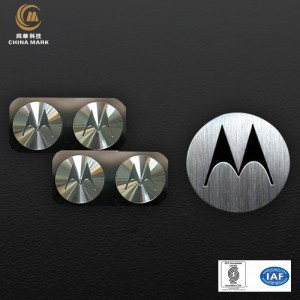

PC Nameplates

| Material | PC, PET |

| Process | -PET cut+printing+ovening+stamping |

| Application | Nameplate for clinic device |

| NW | 25g |

| Mold | Tool opening |

| LT | 7 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Polycarbonate (PC) diaphragm

Polycarbonate (PC), with a density of 1.2g/cm 3, is a new type of thermoplastic engineering plastic, which appeared in the late 1950s. Due to its excellent comprehensive performance, it is widely used and has good effect in nameplates.

PC nameplate material features

(1) wide range of temperature

In a temperature range of 30~130℃, all can adapt, when the temperature changes suddenly, the PC film changes little, so as to ensure that the nameplate can be used in a variety of products in a variety of harsh environment.

(2) good mechanical properties

PC film has a higher impact resistance and high elasticity, its yield point stress is about 60N/mm, is today’s strongest impact resistance plastic, so it is also known as not broken glue, its resilience and fatigue limit strength is a good material for making film panel.

(3) strong processing adaptability

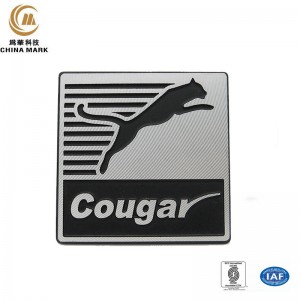

PC film surface can be pressed out of different textures, thereby improving the appearance of the material, can obtain a soft gloss surface;At the same time its surface polarity is higher, to a variety of inks have affinity, suitable for screen printing, also suitable for bronzing, hot pressing.

(4) chemical resistance

It can tolerate dilute acid, weak base, alcohol and alcohol ether.In addition, polycarbonate film has the characteristics of high insulation strength, directionless, high transparency and low atomization.When it through coating or other treatment method, can also improve the surface scratch resistance, chemical resistance and ultraviolet resistance, aging resistance and other characteristics.

You may also like:panel for game machine,stamping nameplate;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:Alum plate

Step 2:Every kind of colored paint

Step 3:Dust-free printing workshop

Step 4:Print each kind of graphics

Step 5:Industry oven, hi-temp, low-temp, constant temp

Step 6:Professional inspector and packaging workers

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA