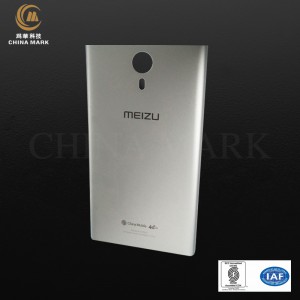

Manufacturing Companies for China Precision Work Fabrication Battery Steel Case Extrusion Enclosure Aluminum Enclosurecase

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Manufacturing Companies for China Precision Work Fabrication Battery Steel Case Extrusion Enclosure Aluminum Enclosurecase, Normally to the majority of business users and traders to offer best quality goods and excellent company. Warmly welcome to join us, let’s innovation collectively, to flying dream.

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Anodized Aluminum Extrusion Case, China Battery Steel Case, Extrusion Enclosure, precision waterproof extruded aluminum enclosure, Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

Precision CNC Machining

| Machines | Alum extrusion machine |

| Processing | - Extrusion+CNC+Anodized+finished edge. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | Phone metal housing |

| NW | 10g |

| Mold | Alum extrusion Mold |

| Mold open cycle | 8 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Precision CNC machining, please consult weihua technology — China precision CNC machining supplier;We have many years of processing experience, support customized, short time limit, timely delivery, low price!

Characteristics of CNC precision machining:

1. Reduce the number of tooling, and do not need complex tooling to process parts with complex shapes;

2. Stable processing quality, high processing precision and high repetitive precision, suitable for aircraft processing requirements;

3. High production efficiency in small batch production;

4. Can process complex surface difficult to be processed by conventional methods, and can even process some processing parts that cannot be observed;

In summary, it is the kind of structure is more complex, the product many batches and small precision parts are more suitable, such as precision shaft, optical fiber tail handle, pin, etc

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA