The meaning of electroforming signs:

Electroforming sign generally refers to a sign made of nickel, then plated with silver or gold, or plated with copper. It is currently considered to be the most high-end logo.The electroforming signs are divided into four layers, the bottom layer is the glue barrier, the second layer is glue, the third layer is the electroforming signs we use, and the fourth layer is composed of a transparent protective film on the surface of the electroforming signs. The surface can be matte or shiny, and the surface can be brushed.

Features of electroforming signs:

1. The degree of environmental pollution is light, no corrosion is required, so it will not cause etching pollution.

2. The process is simple. The electroforming signs do not need any molds, so there is no need to worry about paying high mold costs to make a sign. All the craftsmanship can be completed with a delicate, high-end, high-gloss film. Electroforming signs. Save time, trouble and money.

3. The sample production time is fast, generally only 1-2 days to complete the sample

4. The equipment is simple, the whole production process only needs to use a screen printing platform, baking box, exposure machine, electroplating tank and other basic equipment

5. Less materials, because there is no need for any additional carrier, so the same size of metal sign, the material consumed is 1/7 less than the sign made by the concave-convex etching process.

Height requirements for electroforming signs:

The ideal height of the electroformed nickel sign is generally below 3mm, and the raised part is between 0.4 and 0.7mm. At the same time, the height or depth of the font should not exceed 0.3mm, so that the sign will be more beautiful.

Installation method of electroforming signs:

Generally use strong self-adhesive for pasting, strong weather resistance, very strong and durable.

Application scope of electroforming signs:

Generally used in various household appliances, furniture, such as washing machine logo, refrigerator logo, oven logo, microwave oven logo, air conditioner logo, dishwasher logo, bread maker logo, computer logo, audio logo, perfume bottle logo, wine bottle logo, etc. , The use of electroforming signs will make your products more high-end and magnificent, and the cost will be brand-recognizable. Because electroforming signs have strong gloss, and will reflect different gloss effects according to different angles.

Classification of electroforming signs:

There are two main types of electroforming signs: thick electroforming and thin electroforming (also called nickel plate). In daily life, the application of electroformed nickel signs is very common. The electroformed nickel label is made of nickel sheet casting and plating, the thickness is between 0.03mm~0.1mm (this depends on the customer's requirements), the surface is smooth, flawless, and the accuracy is accurate. It is firmly pasted with strong 3M glue. It's very convenient.

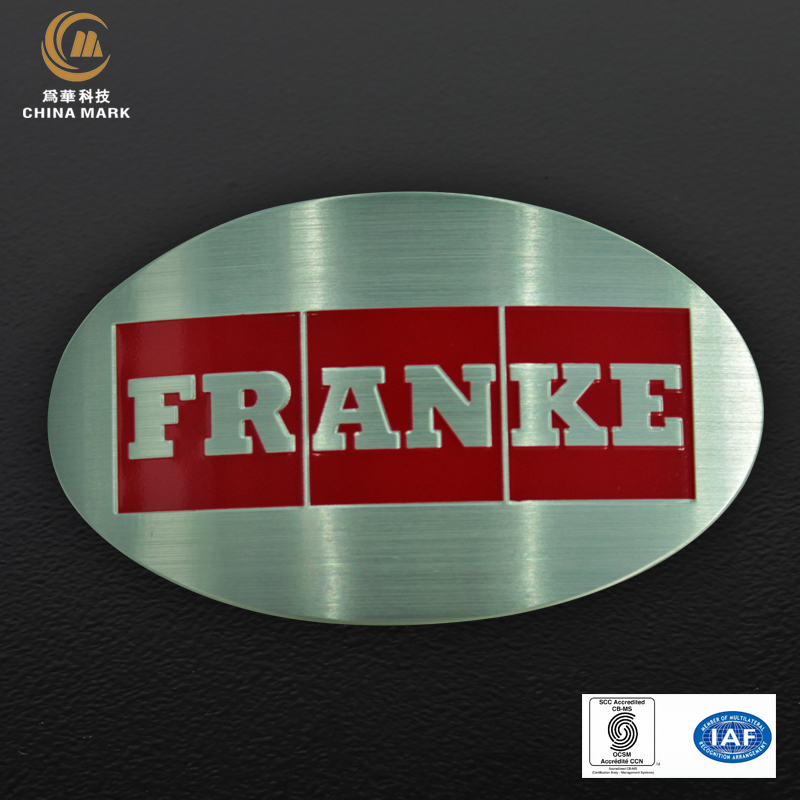

Electroforming sign material, adhesive and surface effect:

The main materials are nickel, brass, gold and chromium; the commonly used adhesives are 3M 7533/3M 9448/3M 467/ 3M468 / hot melt adhesive, etc.; there are many colors available, mainly according to customer needs, usually silver/black/ yellow gold/rose gold/champagne gold; the usual surface effects are bright surface effect, brushing effect, sandblasting effect, reticulate effect and CD effect.

the production process of electroforming signs:

The process of electroforming signs is relatively simple, mainly produced by electroforming, without any molds, and only one film in the entire production process. Save money and time. After the production unit receives the order, it can usually produce samples on the same day and produce products within a few days. Approximate process: drawing-film output-electroforming-color plating-film application-glue application-slitting-packaging-shipment.