New Fashion Design for Copper Name Plate - Custom locker name plates,Nameplate for wardrobe | CHINA MARK – Weihua

New Fashion Design for Copper Name Plate - Custom locker name plates,Nameplate for wardrobe | CHINA MARK – Weihua Detail:

Custom locker name plates

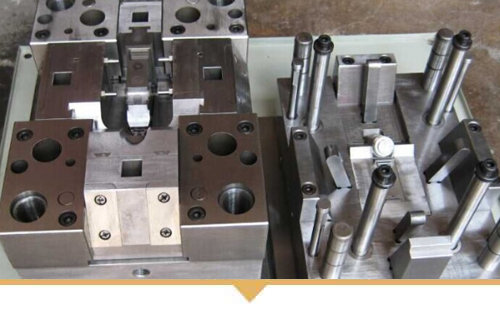

| Material | zinc alloy, alum alloy |

| Process | - Zinc alloy+dissolve+diecast+galvanized+ovening - by die-cast by die-cast machine - further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for wardrobe |

| NW | 180g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology (custom locker name plates manufacturers) fine technology, fast proofing speed, support customer customization, product diversity, quality after-sales service.

What are the commonly used materials for making metal nameplates?

The nameplate is mainly used for furniture and mechanical products. Its existence is not only a sign, but also represents the culture, deposits and strength of the enterprise.So, our business friends, for the hardware sign production, the requirements are more strict.In particular, the sign with what material, is the most concerned about the topic.

Here, in order to let you know more, we here to share the specific material, sign with what?

1, smooth sign: picture or board surface is oily, very smooth sign.

2. Luminous material label: luminous material label (that is, we usually say neon).

3, metal nameplate: in the case of no specially designated plate, the metal as the plate or the main material of the alloy plate.

4, acrylic sign (acrylic) : acrylic material to do the main material of the board sign.

5, electric light plate: the use of light emitting diode or luminous tube to achieve monochrome or color performance.The light-emitting diodes and their performance can be divided into five categories: luminous electro-optical plate, LCD, LED, CRT, FDT, etc.

For China technology mainly undertake trademark, sign orders.Products mainly include computers, mobile phones, audio, refrigerators, air conditioners and other digital home appliances are used on the copper, aluminum, stainless steel nameplates, plastic signs, mirror display, three-dimensional signs, crystal drop plastic signs, nameplate processing, copper signs research and development of all kinds of modern difficult technology metal nameplates, welcome your consultation!

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for New Fashion Design for Copper Name Plate - Custom locker name plates,Nameplate for wardrobe | CHINA MARK – Weihua , The product will supply to all over the world, such as: Austria, Tanzania, Serbia, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.