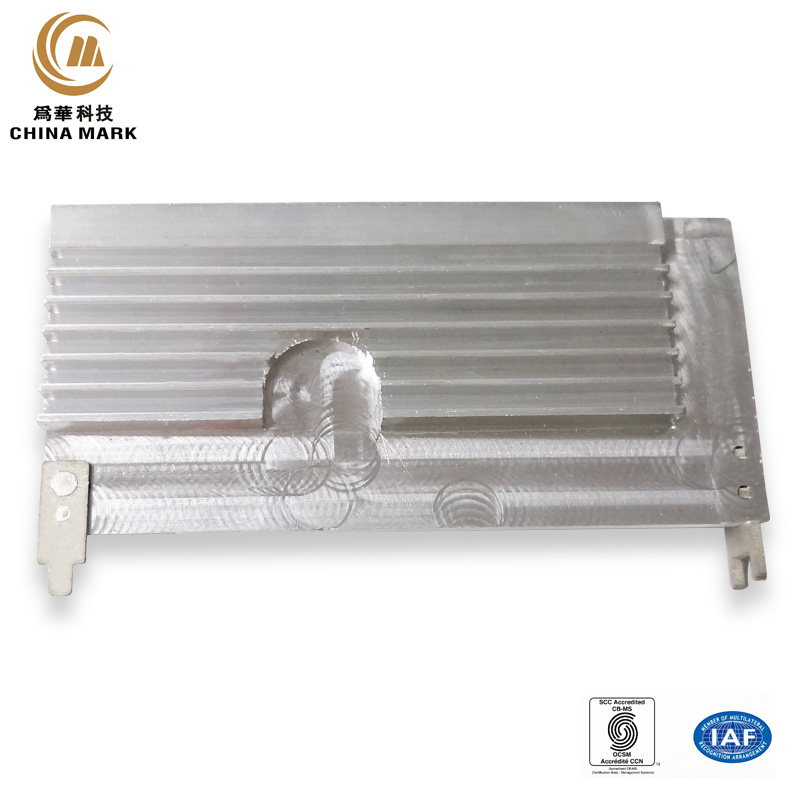

Aluminum extrusion:Is the aluminum alloy (deformation) ingot extrusion molding process with the extruder.

Aluminium alloy extrusion technology

Classification of extruded parts:

Solid section: there are no holes in the section.

Hollow profile: the profile section has holes.

Structure and design of simple extrusion die:

Tube single extrusion die there are two: the first is a solid extrusion die.The second is the hollow profile extrusion die.The specific structure is as follows:

1) extrusion barrel: a multi-layer cylinder body made of high-strength alloy steel, which can be dismounted with inner lining.The length is determined according to the extruder tonnage.Material: coat 5CrMnMo, inner set 3Cr2W8V.

2) mold support: ensure that the mold and the mold pad are concentric, is to install the mold, mold pad auxiliary tools.

3) die pad: the die pad and the die have the same size, its thickness is 3 times of the die thickness, and bear the extrusion pressure together with the die.Die pad, die hole size is slightly larger than the mold.Materials: alloy tool steel.

4) press mouth: auxiliary tools that ensure that the mold does not shift during extrusion and are closely matched with the extrusion barrel. The structure and size are determined according to the tonnage of the extruder.

5) extrusion gasket: auxiliary tool to prevent direct contact between the extrusion shaft and the extruded metal.Its outer diameter is smaller than the inner diameter of the extrusion barrel, and its thickness is between 40 mm and 150mm.

6) extrusion shaft: when the extrusion shaft works, it enters into the extrusion cylinder and contacts with the extrusion pad. The extrusion bearing is subjected to the maximum extrusion pressure of the extruder.Material: 3Cr2W8V.

Die hole configuration principle:

Single hole profile mold hole configuration: generally is to make the mold center of gravity and mold center coincide.If the wall thickness varies greatly, the thinnest part should be arranged in the center of the mold.

Porous profile die hole configuration: for small section or section symmetry is poor, usually used porous mold.The spacing between the holes of the porous mold should not be too small.

Determination of die hole working belt:

1) take the whole section as the benchmark, where the working strip length is (1.5 to 2) times of the finished product thickness.

2) the length of the working band adjacent to the reference point is the length of the working band at the reference point plus 1mm.

3) with the same thickness, the working strip length at the same distance from the center of the mold is the same.

4) starting from the center of the mold, the increase and decrease of the working strip length of each distance of 10mm can be referred to the relevant literature.

5) empty knives in the working belt: too many empty knives will weaken the strength of the working belt of the mold.

Block Angle:

When the length of the die hole working strip is greater than 15 to 25mm, in fact, the metal is no longer fit with the working strip due to size shrinkage, at this time, the metal flow rate can be adjusted by the obstruction Angle.The Angle between the busbar and the extrusion center line of the working belt is the blocking Angle, and the most effective blocking Angle is 3 to 5 degrees.

Flow Angle: generally, the flow Angle is a symmetrical cone or an inclined cone on the working end face of the mold.

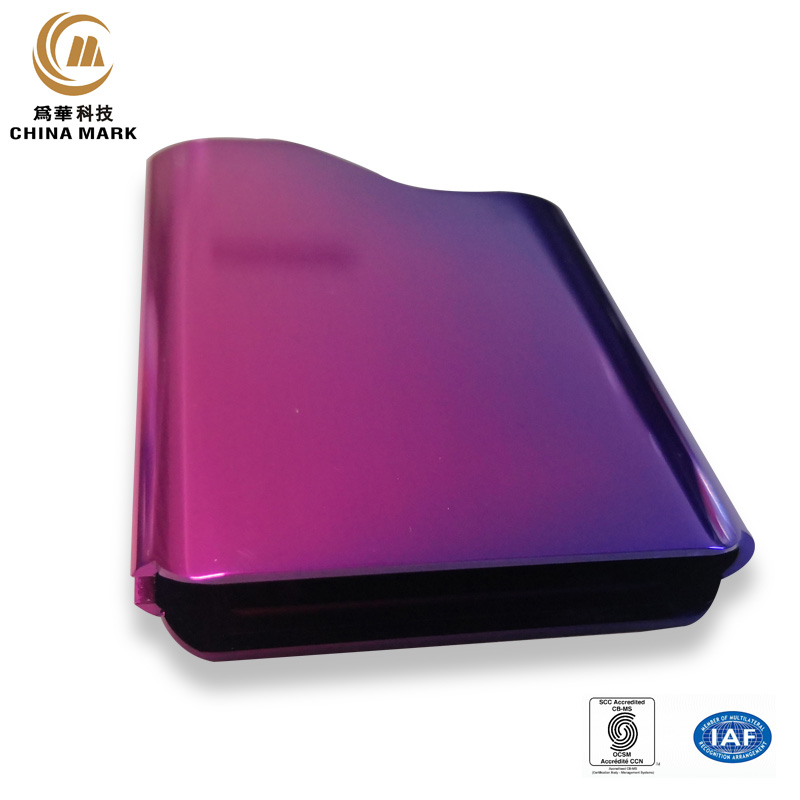

The above is about what is aluminum extrusion and aluminum extrusion technology related introduction;We are a professional aluminum extrusion fabrication enterprises, can provide: arc aluminum extrusion, triangle aluminum extrusion and other customized processing services;Welcome to consult ~

Post time: Apr-11-2020