Ndondomeko ya Aluminium extrusion

Njira ya aluminium alloy extrusion imayambira ndi kapangidwe kazinthuzo, chifukwa kapangidwe kake kamakhala kogwiritsa ntchito momwe ntchito imagwirira ntchito, yomwe imatsimikizira magawo ambiri omaliza a malonda. Monga momwe makinawo amagwirira ntchito, magwiridwe antchito am'maso ndi kugwiritsa ntchito zofunikira zachilengedwe , izi ndizofunikira zimatsimikizira kusankha kwa aloyi ya extruded aluminium.

Komabe, katundu wa zotayidwa zotulutsidwa zimatsimikizika ndi kapangidwe kake ka mankhwalawo. Mawonekedwe a malonda amatengera mawonekedwe a extrusion die.

Akathetsa vuto lakapangidwe, njira yothandizila extrusion ikuyamba extrusion kuponyera mu ndodo ya aluminiyamu, ndodo ya aluminium yoponyera iyenera kutenthedwa isanachitike extrusion kuti ichepetse, zotenthetsera zabwino zotayidwa zopangira ndodo sheng ingot zimayikidwa mu mbiya ya extruder mkati, kenako mphamvu yamphamvu yamagetsi kukankhira ndodo ya extrusion, kumapeto kwa ndodo ya extrusion kuli ndi pini yothinikiza, yotenthetsera zotsekemera zotsekemera zotsekemera mu dummy block pansi pakukakamizidwa kwambiri kuchokera ku nkhungu mwatsatanetsatane akamaumba extrusion.

Izi ndi zomwe nkhungu ndi: mawonekedwe a chinthu chofunikira pakupanga.

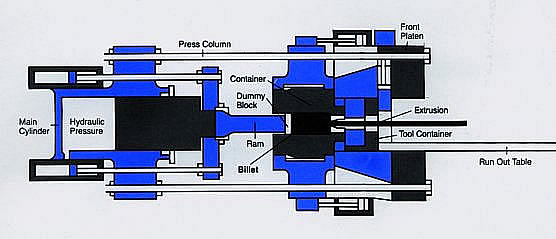

Chithunzichi ndi: chithunzi chopingasa cha hydraulic extruder schematic

Malangizo a extrusion amachoka kumanzere

Uku ndikulongosola kosavuta kwa extrusion yomwe imagwiritsidwa ntchito kwambiri masiku ano. Kutulutsa kosawonekera ndi njira yofananira, koma pali zosiyana zina zofunika kwambiri.

Imfa imayikidwa pa bar yopanda dzenje la extrusion, kotero kuti imfayo imakanikizidwa kupita ku bar ya aluminiyamu yosasunthika, ndikukakamiza aloyi ya aluminiyamu kuti ipite kulowera kwa bar yopanda pake.

M'malo mwake, njira ya extrusion ndiyofanana ndikufinya mankhwala otsukira mano. Vutoli likagwiritsidwa ntchito kumapeto kotsekedwa kwa mankhwala otsukira mano, mankhwala opangira mano amafinyidwa potsegulira kozungulira.

Ngati kutsegula kuli kopanda pake, mankhwala otsukira mano amatuluka ngati riboni.

Zachidziwikire, mawonekedwe ovuta amathanso kufinyidwa kutseguka kwa mawonekedwe omwewo Mwachitsanzo, opanga makeke amagwiritsa ntchito machubu opangidwa mwapadera kufinya ayisikilimu kuti apange mitundu yonse yazokoma.

Ngakhale simungathe kupanga zinthu zambiri zothandiza ndi mankhwala otsukira mano kapena ayisikilimu, simungathe kufinya zotayidwa m'machubu ndi zala zanu.

Koma mutha kugwiritsa ntchito makina osindikizira amadzimadzi kuti mutulutse zotayidwa kuchokera pachikombole chake kuti mupange zinthu zingapo zothandiza zamtundu uliwonse.

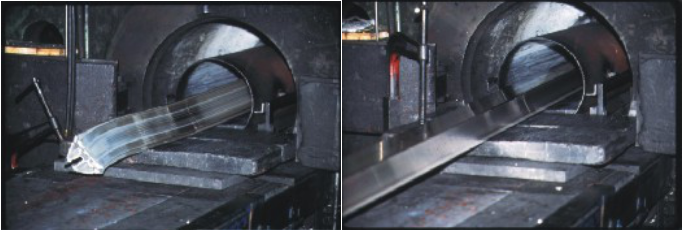

Chithunzi pansipa (kumanzere) chikuwonetsa gawo loyamba la extruder koyambirira kwa extrusion. (kumanja)

Bala

The zotayidwa bala ndi akusowekapo za ndondomeko extrusion. Chitsulo cha aluminiyamu chomwe chimagwiritsidwa ntchito popanga extrusion chimatha kukhala cholimba kapena chopanda pake, nthawi zambiri chimakhala chachitsulo, ndipo kutalika kwake kumatsimikiziridwa ndi chubu cha extrusion.

Ndodo Aluminiyamu nthawi zambiri amapangidwa ndi kuponyera, kapena kulipira kapena ufa kulipira.It nthawi zambiri amapangidwa ndi kudula mipiringidzo aloyi zotayidwa ndi zikuchokera wabwino aloyi.

Alloys aluminiyamu nthawi zambiri amakhala ndi zinthu zopitilira chimodzi. Alloys yotulutsika ya aluminiyumu imapangidwa ndi zinthu zochepa (nthawi zambiri zosaposa 5%) (monga mkuwa, magnesium, silicon, manganese, kapena zinc) zomwe zimapangitsa kuti zinthu zizikhala ndi aluminium yoyera komanso zimakhudza extrusion process.

Kutalika kwa ndodo ya aluminiyumu kumasiyana kuchokera pakupanga mpaka wopanga, komwe kumatsimikizika ndi kutalika kofunikira komaliza, kuchuluka kwa extrusion, kutalika kwa kutulutsa ndi cholowa cha extrusion.

Kutalika kwanthawi zambiri kumakhala kuyambira mainchesi 2660mm mpaka mainchesi 72 (1830mm). Kunja kwa diamondi kumayambira mainchesi 3 (76mm) mpaka mainchesi 33 (838mm), mainchesi 6 (155 mm) mpaka mainchesi 9 (228 mm).

Njira zowongolera mwachindunji

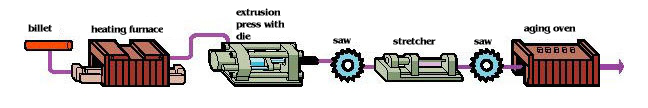

[billet] [chotenthetsera] [extrusion makina okhala ndi die] saw [strecher] [kukalamba overn]

Chithunzicho chikuwonetsa njira zoyambira zotulutsira kapamwamba ka aluminiyumu

Chojambula chomaliza chikatsimikizika, aloyi aloyi amasankhidwa, kupanga kwa extrusion kumalizika, ndikukonzekera njira yeniyeni ya extrusion kumalizika.

Kenako preheat bala ya aluminium ndi chida cha extrusion. Munthawi ya extrusion, bala ya aluminiyamu ndiyolimba, koma yasintha m'ng'anjo.

Malo osungunuka a aluminiyamu alloy ndi pafupifupi 660 The .Kutentha kotentha kwamachitidwe a extrusion nthawi zambiri kumakhala kwakukulu kuposa 375 ℃ ndipo kumatha kukhala 500 ℃, kutengera mtundu wazitsulo.

Njira yeniyeni ya extrusion imayamba pamene ndodo ya extrusion imayamba kukakamiza ndodo ya aluminium mu ingot.

Makina osindikizira osiyanasiyana amapangidwa kuti afinyire paliponse kuchokera matani 100 mpaka matani 15,000.Matenthedwewa a extrusion amatsimikizira kukula kwa extrusion wopangidwa ndi makina a extrusion.

Mafotokozedwe owonjezera a malonda amawonetsedwa ndi kukula kwakukulu kwa mtanda wa chinthucho, nthawi zina komanso ndi gawo lazungulira la malonda.

Extrusion itangoyamba kumene, bala ya aluminiyamu imayang'aniridwa ndi mphamvu ya nkhungu ndipo imakhala yayifupi komanso yolimba, mpaka kufalikira kwa bar ya aluminium kumangolekedwa ndi khoma la ingot;

Ndiye, pamene kupanikizika kukukulirakulira, chitsulo chofewa (cholimba) sichikhala ndi malo oyenda ndipo chimayamba kufinyidwa kuchokera kubowo lankhungu mpaka kumapeto ena a nkhunguyo, ndikupanga mbiri.

Pafupifupi 10% ya ndodo ya aluminium (kuphatikiza khungu la aluminiyamu ndodo) imatsalira mu mbiya ya ingot, mankhwala a extrusion amadulidwa kuchokera ku nkhungu, ndipo chitsulo chotsalira mumtsuko wa ingot chimatsukidwa ndikuwonjezeredwa. njira yotsatira ndikuti chotentha chotulutsa extrusion chimazimitsidwa, makina ndi okalamba.

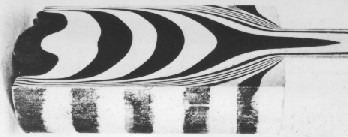

Aluminiyamu wotentha akamachotsedwa pachikombocho kudzera mu ingot silinda, chitsulo chomwe chili pakatikati pa baramu ya aluminiyamu chimayenderera mwachangu kuposa m'mphepete mwake. Monga mzere wakuda wa m'fanizoli ukuwonetsera, chitsulo m'mbali mwake chimatsalira kuti chibwezeretsedwe ngati otsalira.

Mlingo wa extrusion umadalira aloyi yemwe amafinyidwa ndi mawonekedwe a dzenje lofa. Kugwiritsa ntchito aloyi wolimba kuti mufinyete zinthu zopangidwa mwaluso kumatha kukhala pang'onopang'ono ngati 1-2 mapazi pamphindi. Ndi ma alloys ofewa, mawonekedwe osavuta amatha kufinyidwa mpaka 180 mapazi mphindi kapena kupitilira apo.

Kutalika kwa mankhwala a extrusion kumadalira pa bar ya aluminiyamu ndi dzenje lakutulutsira nkhungu. Extrusion yopitilira imatha kupanga chinthu mpaka kutalika kwa 200. Kutulutsa kwaposachedwa kwambiri, pomwe mankhwala omwe amachotsedwayo achoka pa extruder amaikidwa pa slide (chofanana ndi lamba wonyamula);

Malinga ndi aloyi osiyana, kutulutsa kunja kwa njira yozizira yazogulitsa: kugawidwa kuzizira kwachilengedwe, mpweya kapena kuziziritsa kwamadzi koma kuzimitsa .Ichi ndichofunikira kwambiri kuti zitsimikizire kuti ntchitoyo imagwiranso ntchito munthu atakalamba. bedi lozizira.

Wongolani

Pambuyo pa kuzimitsa (kuzirala), chinthu chomwe chimatulutsidwa chimawongoka ndikuwongoleredwa ndi machira kapena chowongolera (kutambasula kumadziwikanso kuti kuzizira pambuyo pa extrusion) .Pomaliza, mankhwalawo amasamutsidwa kumakina osakira ndi chida cholozera.

Kumanga

Kuphika kumapangidwe azinthu ndizocheka kwa chinthu china mpaka kutalika kwamalonda. Ma macheka ozungulira ndi omwe amagwiritsidwa ntchito kwambiri masiku ano, monga macheka oyenda mozungulira omwe amadula zidutswa zazitali zakutali.

Palinso macheka odulidwa kuchokera pamwamba pa mbiri (monga macheka amagetsi a magetsi). Tebulo lothandiza macheka, tebulo la macheka lili ndi tsamba la macheka kuchokera pansi mpaka kudula mankhwala, kenako tsamba la macheka kubwerera pansi za tebulo lotsatira.

Macheka ozungulira omwe amakhala omaliza amakhala mainchesi 16-20 m'mimba mwake ndipo ali ndi mano opitilira 100 a carbide. Masamba akulu amawagwiritsa ntchito pazotulutsa zazikulu zazikulu.

Makina ochepera odziyipitsira amakhala ndi makina omwe amapereka mafuta opangira mafuta ku sawtooth kuti awonetsetse kuti akadula moyenera komanso pamwamba pa macheka.

Makina osindikizira amangogwirizira zigawozo kuti acheke ndipo zinyalala zimasonkhanitsidwa kuti zibwezeretsedwe.

Okalamba:

Zinthu zina zomwe zimatulutsidwa zimafunikira ukalamba kuti ukhale ndi mphamvu yokwanira, motero umatchedwanso kukalamba.Kukalamba kwachilengedwe kumachitika kutentha kwapakatikati.Kukalamba kwapangidwe kumachitika mu ng'anjo yokalamba.Tekinoloje, amatchedwa mpweya wokhathamira kwambiri.

Mbiriyo ikatulutsidwa kuchokera kwa wotulutsayo, mbiriyo imakhala yolimba koma posakhalitsa imakhazikika ikakhazikika kapena kuzimitsidwa (ngakhale itakhazikika ndi mpweya kapena madzi).

Mitengo ya aluminiyamu yopanda kutentha (monga zotayidwa ndi aluminiyamu yokhala ndi magnesium yowonjezera kapena manganese) imalimbikitsidwa ndi ukalamba wachilengedwe komanso kuzizira. Kutentha kwa aloyi zotayidwa (monga zotayidwa ndi aluminium ndi mkuwa, zinc, magnesium + silicon) imatha kupeza mphamvu komanso kuuma kwabwino pokhudzidwa ndi kutentha kwa mawonekedwe a allo metallographic.

Kuphatikiza apo, ukalamba ndikupanga tinthu tating'onoting'ono tomwe tidagawika mofananamo kuti tipeze mphamvu yayikulu yazokolola, kuuma ndi kukhazikika kwa aloyi wapadera.

Bales

Kaya ng'anjo yokalamba kapena kutentha kwa firiji kukalamba, mutakalamba kwathunthu, mbiriyo imasamutsidwira kuchipatala chapamwamba kapena malo ogwirira ntchito kapena mabele okonzeka kunyamula makasitomala.

Anthu amafunsanso

Post nthawi: Mar-20-2020