One of Hottest for China Custom Die-Casting Zinc Alloy Metal Case,Die Cast Zinc Plating Shell

As a way to ideal meet up with client’s desires, all of our operations are strictly performed in line with our motto “High Top quality, Competitive Cost, Fast Service” for One of Hottest for China Custom Die-Casting Zinc Alloy Metal Case,Die Cast Zinc Plating Shell, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

As a way to ideal meet up with client’s desires, all of our operations are strictly performed in line with our motto “High Top quality, Competitive Cost, Fast Service” for China Precision CNC Mechanical Parts, OEM Factory Zinc Alloy Metal Plating Housing, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable items quality , increase customers’ satisfaction and achieve win-win situation .

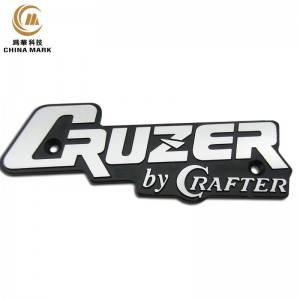

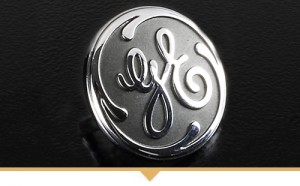

Metal logo plates

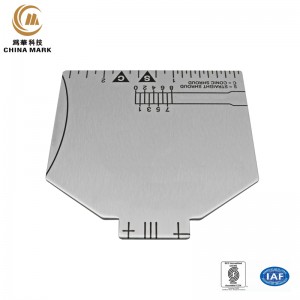

| Material | zinc alloy, alum alloy |

| Process | - Zinc alloy+dissolve+diecast+galvanized+ovening+oiling+ovening - by die-cast by die-cast machine- further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for car |

| NW | 240g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology (company logo plates) professional production of metal plate etching, first-class technology and service for you to create satisfactory products!Price concessions, delivery on time!Gold engraved name plates to find for China technology!

Metal alloy plate

Main USES: furniture, wine bottle (box), tea box, luggage, door, car, etc.

Material: zinc alloy/copper/iron

Main processes: die casting, polishing, sand cleaning, electroplating, coloring.

Main installation method: strap double-sided tape or two side hole with small nails.

Product features:

1, the design is fashionable, delicate and exquisite, convenient to carry, send yourself to send a lover, send a good choice of friends.

2, delicate and small, the shape is changeable, always reflect your mood, show your personality, show your taste.

3, the use of environmental protection true/imitation gold plating, sweat resistance, wear resistance, durable, environmental protection and allergy, color retention time is long.

Advantages: style, decorative patterns and shape plasticity, concave and convex three-dimensional sense of strong, strong metal texture.

You may also like:nameplate for electronic furnace;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

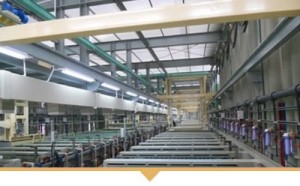

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA