Professional China Logo Plates - Metal name badges,Electroformed nameplate | WEIHUA – Weihua

Professional China Logo Plates - Metal name badges,Electroformed nameplate | WEIHUA – Weihua Detail:

The best and most trouble-free electroforming signs:

Speaking of electroforming signs, professional signs, hardware industry engineering, business and technical personnel have long been familiar with electroformed logo, but for non-industry personnel may be relatively unfamiliar. Now, our HUIZHOU WEIHUA TECHNOLOGY will show you some details of electroforming signs for you.

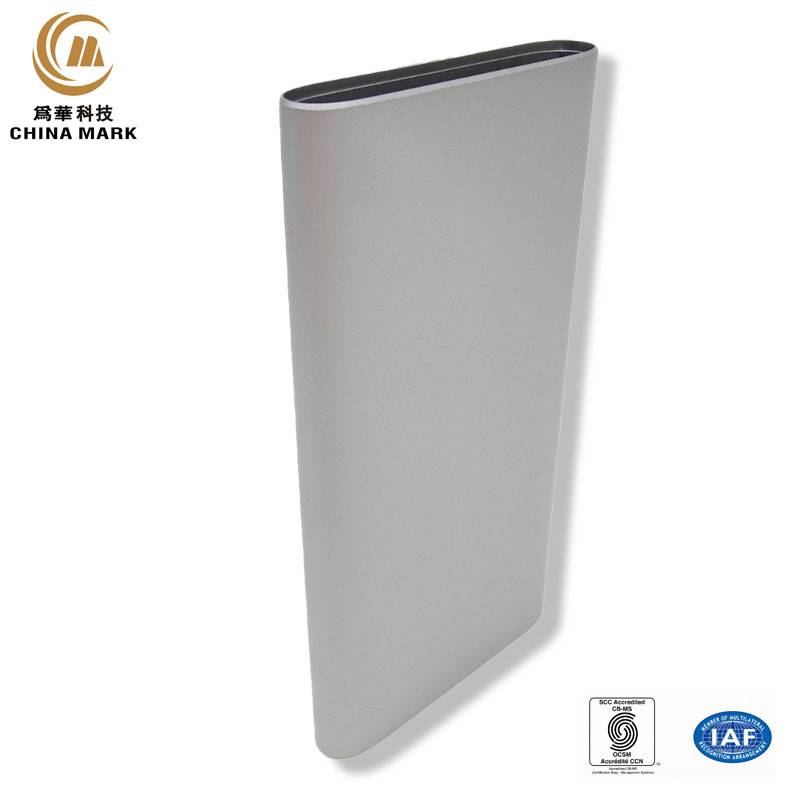

Name: Electroforming thick nameplate

Material: Nickel or brass or copper is ok

Size: 52*27*0.8mm

Process: electroforming + background spray black ink + electroplating chrome color, font bright silver + apply 3M468 adhesive

Estimated unit price of the product: RMB 3~12, the final cost is determined according to the product structure

MOQ: 500 pieces. Unlimited number of proofing.

Do this need to open the mold: Yes

Purpose: used in optical testing equipment

The metal sign from Huizhou Weihua Technology is a team with professional production and design experience. It will not charge additional startup costs or additional design costs.

Our advantages are as follows:

- Quality based on price

- No signage startup fees and custom design fees

- Can provide a variety of color options, tell us Pantone color number, or other designated color number is ok.

- We can provide 10-20 free samples of different styles for customers to view, except for the freight charges that need to be borne by the customer (generally, the range of express delivery costs is $15-$62.5, unless the price will be different in remote areas)

- Long-term friendly cooperation with many major customers at home and abroad, such as BYD, TCL, BOSE, Harman Kardon, KitchenAid, etc.

- Passed IATF16949 and ISO9001 certification

- We can provide professional test requirements such as methyl ethyl ketone, 100 grid, 2.5 dimensional, salt spray, film thickness, friction resistance, tape retention, ultraviolet aging, etc., and provide corresponding reports for free.

- Can be shipped worldwide by express, sea and air, regardless of geographical restrictions

If you have any items about signs, please quickly pick up the phone in your hand and call our business phone: 0086+19926691505, or send an email to our business

The meaning of electroforming signs:

Electroforming sign generally refers to a sign made of nickel, then plated with silver or gold, or plated with copper. It is currently considered to be the most high-end logo.The electroforming signs are divided into four layers, the bottom layer is the glue barrier, the second layer is glue, the third layer is the electroforming signs we use, and the fourth layer is composed of a transparent protective film on the surface of the electroforming signs. The surface can be matte or shiny, and the surface can be brushed.

Features of electroforming signs:

1. The degree of environmental pollution is light, no corrosion is required, so it will not cause etching pollution.

2. The process is simple. The electroforming signs do not need any molds, so there is no need to worry about paying high mold costs to make a sign. All the craftsmanship can be completed with a delicate, high-end, high-gloss film. Electroforming signs. Save time, trouble and money.

3. The sample production time is fast, generally only 1-2 days to complete the sample

4. The equipment is simple, the whole production process only needs to use a screen printing platform, baking box, exposure machine, electroplating tank and other basic equipment

5. Less materials, because there is no need for any additional carrier, so the same size of metal sign, the material consumed is 1/7 less than the sign made by the concave-convex etching process.

Height requirements for electroforming signs:

The ideal height of the electroformed nickel sign is generally below 3mm, and the raised part is between 0.4 and 0.7mm. At the same time, the height or depth of the font should not exceed 0.3mm, so that the sign will be more beautiful.

Installation method of electroforming signs:

Generally use strong self-adhesive for pasting, strong weather resistance, very strong and durable.

Application scope of electroforming signs:

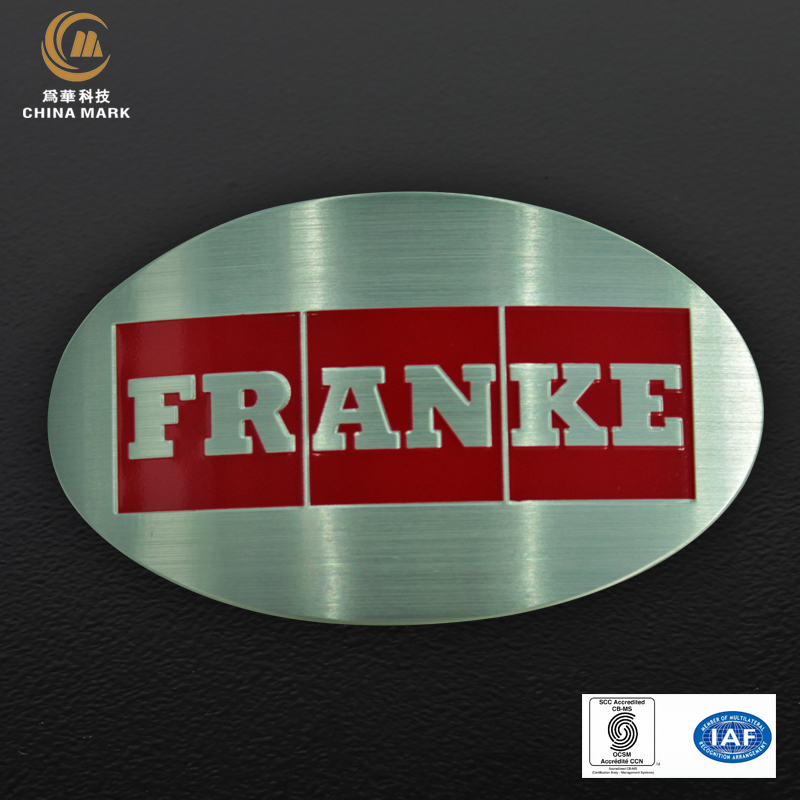

Generally used in various household appliances, furniture, such as washing machine logo, refrigerator logo, oven logo, microwave oven logo, air conditioner logo, dishwasher logo, bread maker logo, computer logo, audio logo, perfume bottle logo, wine bottle logo, etc. , The use of electroforming signs will make your products more high-end and magnificent, and the cost will be brand-recognizable. Because electroforming signs have strong gloss, and will reflect different gloss effects according to different angles.

Classification of electroforming signs:

There are two main types of electroforming signs: thick electroforming and thin electroforming (also called nickel plate). In daily life, the application of electroformed nickel signs is very common. The electroformed nickel label is made of nickel sheet casting and plating, the thickness is between 0.03mm~0.1mm (this depends on the customer’s requirements), the surface is smooth, flawless, and the accuracy is accurate. It is firmly pasted with strong 3M glue. It’s very convenient.

Electroforming sign material, adhesive and surface effect:

The main materials are nickel, brass, gold and chromium; the commonly used adhesives are 3M 7533/3M 9448/3M 467/ 3M468 / hot melt adhesive, etc.; there are many colors available, mainly according to customer needs, usually silver/black/ yellow gold/rose gold/champagne gold; the usual surface effects are bright surface effect, brushing effect, sandblasting effect, reticulate effect and CD effect.

the production process of electroforming signs:

The process of electroforming signs is relatively simple, mainly produced by electroforming, without any molds, and only one film in the entire production process. Save money and time. After the production unit receives the order, it can usually produce samples on the same day and produce products within a few days. Approximate process: drawing-film output-electroforming-color plating-film application-glue application-slitting-packaging-shipment.

Read more news

What technology does the metal nameplate have

How to distinguish metal nameplate

The surface treatment process of metal nameplate is introduced

Learn more about WEIHUA products

aluminum extrusion enclosure

stainless steel name plates engraved

metal name plates suppliers

The main process shows as below

Step 1:Alum plate

Step 2:Printing mesh-plate maker

Step 3:Every kind of colored paint

Step 4:Dust-free printing workshop

Step 7:Professional inspector and packaging workers

Step 5:Print each kind of graphics

Step 6:Industry oven, hi-temp, low-temp, constant temp

![]()

If you are interested in getting in touch with a our sales rep click here

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with Professional China Logo Plates - Metal name badges,Electroformed nameplate | WEIHUA – Weihua , The product will supply to all over the world, such as: Milan, Malta, Italy, We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.