Aluminium extrusion maitiro:

Chaicho extrusion chakatanga ne extrusion yakakandwa mualuminium tsvimbo, aruminiyamu yekukanda tsvimbo inofanira kudziyirwa pamberi pe extrusion kuti iinyorove, iyo yekudziya yakanaka aruminiyamu yekukanda tsvimbo sheng ingot inoiswa mune yekuwedzera dhiramu mukati, uye ndokuzo fambiswa neakakwira-simba hydraulic extrusion tsvimbo, iyo kumberi kwekupedzisira kweiyo tsvimbo yekutsveta ine pini yekumanikidza, yakadai inopisa yakapfava aluminium alloy mune dummy block pasi yakasimba kumanikidzwa kubva kuforoma chaiyo kuumbwa extrusion, tora chekupedzisira chigadzirwa.

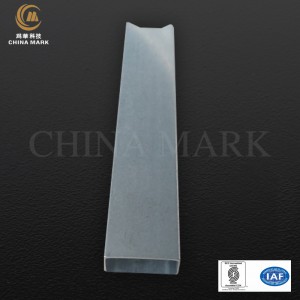

Iyo aluminium bar ndiyo isina chinhu yeiyo extrusion maitiro. Iyo aluminium bhaa ye extrusion inogona kunge yakasimba kana isina mhango, kazhinji cylindrical, uye kureba kwayo kunogadziriswa neiyo extrusion spindles.Aluminium mabara anowanzo kukandwa, mamwe akaumbirwa kana kumanikidzwa.Iyo inowanzoitwa nekucheka aluminium alloy mabhagi ane yakanaka alloy kuumbwa.Iwo matanda anowanzo svitswa kusvika pamadhigirii mazana mana (450 degrees) muvira rinopisa usati watumirwa kuumbika, pamwe neinenge gumi muzana yasara mukati meiyo ingots.

Kupatsanura kwenzira dzekuwedzera.

1. Zvinoenderana nechero extrusion nzira: kumberi extrusion, reverse extrusion, lateral extrusion

2. Zvinoenderana ne deformation hunhu: ndege deformation extrusion axial symmetry deformation extrusion general-dimensional deformation extrusion

3. Zvinoenderana nerekuti lubrication nyika: hapana lubrication extrusion lubrication extrusion yakanaka lubrication extrusion

Zvakanakira extrusion kugadzira:

1. Kuvandudza deformation kugona kwesimbi

Iyo extrusion ratio ye pure aluminium inogona kusvika mazana mashanu, iyo extrusion reshiyo yemhangura yakachena inogona kusvika mazana mana, uye iyo extrusion reshiyo yesimbi inogona kusvika 40-50.

2. Zvigadzirwa zvekuwedzera zvine mhando yepamusoro yepamusoro

Iyo extrusion deformation inogona kuvandudza iyo microstructure uye mekutengesa zvivakwa zvesimbi zvinhu, kunyanya kune mamwe maaluminium alloys ane extrusion mhedzisiro, iyo longitudinal (extrusion nzira) mechina zvivakwa zvezvinhu zvakabuditswa mushure mekudzima uye kuchembera zvakakwirira zvakanyanya kupfuura zvakafanana zvigadzirwa zvinogadzirwa nedzimwe nzira dzekugadzirisa. .

3. Zvigadzirwa zvekuwedzera zvine huwandu hwakawanda

Kugadziriswa kwekuwedzeredza hakugone chete kugadzira pombi, tsvimbo uye waya ine yakapusa chikamu chimiro, asi zvakare inogona kuburitsa yakasimba uye isina mhango zvikamu zvine yakaoma kunzwisisa chikamu chikamu, uye inowirirana chikamu zvikamu nekushomeka shanduko uye zvishoma nezvishoma shanduko pamwe nehurefu hwekutungamira kwechikamu chechigadzirwa.

Huwandu hwehukuru hwakakurawo kwazvo, kubva pamachubhu akakura kwazvo uye maprofiles ane zvikamu zvine denderedzwa rekunze dhayamita ye500-1000mm kusvika kudiki kwazvo kunyatsoburitsa ine zvikamu saizi yematches.