Makore makumi maviri ezviitiko mukutonhora / kudhirowa / kupisa kwekugadzira indasitiri yealuminium alloy, inotarisana nekuvhura kufa uye kubaya / kudhirowa / kugadzira / kugadzirwa kweCNC uye kugadziriswa kwearuminiyamu zvigadzirwa, aluminium extrusion muforoma

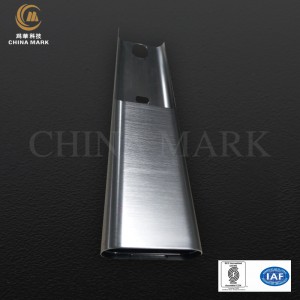

Aluminium extrusion yeChina sainzi uye tekinoroji, anoshandiswa zvakanyanya, akakwana zvikamu, mhando yepamusoro, yekutanga-kirasi sevhisi, kukanganisa extrusion aruminiyamu kunogona kugadziridzwa zvinoenderana nezvinodiwa zvakasiyana, gamuchira kubvunza;

Aluminium extrusion yekugadzira extrusion maitiro

Maitiro ekushanda:

1. Pisai ingot humburumbira kusvika pa380 ℃ - 420 ℃ muchimiro chekupisa gradient ye100 ℃ / 1 awa.

2. Maererano nehurongwa hwekushanda pepa, sarudza iyo yakakodzera huwandu hwakakodzera hwealuminium bhaira kudziya kune 480 ℃ - 520 ℃, akakosha maindasitiri profiles zvinoenderana neyakatsanangurwa maitiro tembiricha.

3. Zvinoenderana nehurongwa hwekushanda, sarudza chakuumba zvinoenderana nechirongwa, chidziise kusvika pa460 ℃ - 500 ℃, uye chengeta ichidziya kwemaawa maviri kusvika mana.

4. Tanga iyo extruder inotonhora mota - mafuta mota.

5. Zvinoenderana nehurongwa humwe chete hwechirongwa, sarudza yakakosha kushoni yeforoma kuti iiswe muforoma base, uye unokiya chigadziko cheforoma munzvimbo yekuwedzera.

6. Vhara dhiramu rinobata uye simudza iyo inopisa simbi yealuminium kune chinowirirana chinzvimbo cheiyo nduru yegirazi nekushandisa iyo yekudyira pani.

7. Tenzi humburumbira mberi extrusion

8. Iyo yekutanga yekumhanyisa kumhanya inofanirwa kunonoka, uye iyo yepakati kumhanya inofanirwa kugadziriswa zvinoenderana nepamusoro pehunhu hweprofile pane iyo nzira yekubuda.

9. Rekodha iyo nhamba yeforoma, aruminiyamu bar nhamba, tenzi humburumbira kumanikidza uye kuburitsa kumhanyisa zvakadzama mune yekutanga rekodhi.

Ii. Maitiro anodikanwa

1. Tembiricha yealuminium tsvimbo inopisa pamushini ndeiyi: A flat die: 500 ℃ - 520 ℃ b. kupatsanurwa kufa: 480 ℃ - 500 ℃ c. akasarudzika maindasitiri zvinhu zvinoitwa zvinoenderana neakasarudzika maitiro zvinodiwa

2.Mold kupisa nzira: a. flat kufa: 460 ℃ - 480 ℃ b. kupatsanurwa kufa: 460 ℃ - 500 ℃

3.Kuisa tembiricha tembiricha: 380 ℃ - 420 ℃ yekupedzisira nzvimbo tembiricha yeiyo ingot chubhu iri 280 ℃ - 360 ℃

4. Iyo yakadzoserwa zvinhu inofanirwa kuve neyakagadzika pamusoro, isina ruoko rwekunzwa kwehurefu hwenzvimbo, yakanaka uye kunyange yekudyara zviyo, isina yakajeka bhandi, mutsetse mutema, ndege gwanza pakati peYin neYang ndege, Angle kutsauka, uye iyo yekucheka Angle inofanira kunge iri yepamusoro chaiyo nhanho zvinoenderana neyakajairwa nyika.

5.Kudzvinyirira kwekuwedzera: ≤200㎏ / cm2

6 nduru yekuvharira kumanikidza 120㎏ / cm2 - 150㎏ / cm2.

7.Tembiricha ye hydraulic mafuta ≤45 ℃

8. Mbiri yekumhanyisa kubuda inowanzo kudzorwa mu: 5 m / min -30 m / min

10. Yese extrusion yematanda makumi masere -100-tsvimbo zana, inofanirwa kushandisa yakakoshwa yakachena silinda pamushoni kuchenesa iyo bile.

Tatu. Nyaya dzinoda kutariswa

1. Panguva yekuwedzeredzwa, kana iyo kufa ikavharwa, iyo nguva yekufa haifanire kupfuura masekondi mashanu.

2. Paunenge uchiisa muforoma, nyatsoteerera kuchengetedzwa uye kudzivirira sikuruu kuti isatsvedze nekutyora tsoka.

3. Kana uchidhonza, zvakanyatsorambidzwa kutarisisa zvakananga kuburitsa.

4. Usati wamisa iyo die, nzvimbo yepakati inofanirwa kuongororwa uye tsvimbo ye extrusion inofanira kuenderana. Iyo isina-mutoro bvunzo muchina unofanirwa kumhanyisa kamwe usati watanga muchina.

5. Kunyangwe tembiricha yetambo yekuyera, chakuvhu uye ingot barrel inosangana nezvinodiwa.

6.3 - tarisa mhando yematanda mashanu kamwe.

Tarisa tembiricha yemafuta kazhinji.

8. Kunyangwe yega aruminiyamu bhaa inoratidzirwa nenhamba yevira uye nhamba yemubairo.