Theknoloji ea Weihua (litsi tsa machining tsa aluminium extrusion) liindasteri aluminium - aluminium profil hlobo - extrusion - bokaholimo - ho phethela, ts'ebeletso e le 'ngoe, likhoebo tsa setifikeiti; Re tsepamisa maikutlo ho: CNC aluminium extrusion, likarolo tse rarahaneng tsa ts'ebetso ea CNC, likarolo tse sa tloaelehang tsa ts'ebetso ea CNC, 1 Bahlahisi ba ts'ebetso ea moeli oa li-inch tse 100, koloi e lekolang komporo, mohala oa thelevishene, mokhoa oa ho sebetsana le moeli, o amohela 'mapa ka tloaelo

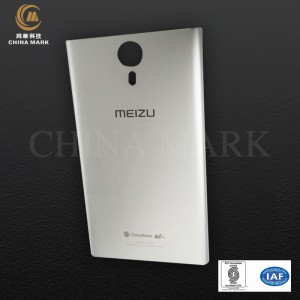

Melemo ea nyeoe ea selefouno ea aluminium

PC ea setso, ABS le thepa e 'ngoe ea polasetiki matlo, ba ikutloa ba futsanehile, thepa e le tlase, moralo o fokolang, phello e futhumetseng ea mocheso, ts'ireletso e tlase ea likarolo tsa kahare tsa motlakase Ponahalo e ncha ea nyeoe ea tšepe ea mohala oa tšepe,' mala o motle, ts'ebetso e ntle, ho hlōla mefokolo ea nyeoe ea polasetiki, e fetohile karolo e ka sehloohong ea lihlahisoa tsa likhetla tsa mehala ea mohala.

Aluminium alloy shell e entsoe ka lisebelisoa tsa aluminium alloy, bokaholimo ba aluminium kamora 'mala oa oxidation, ponahalo e ntle, boemo bo phahameng, botle bo khabisitsoeng; E manganga le litšila, e bonolo ho e hloekisa ebile e lula e hloekile; Ts'ebetso e bonolo, maemo a phahameng, indastering ea elektroniki ea IT mohala lifono, ipads, linyeoe tsa likhomphutha le likarolo tse ling li sebelisitsoe haholo.

(1) ponahalo e mosa, 'mala o motle le benya;

(2) phutholohile ikutloa, fesheneng le phahameng sehlopheng;

(3) roala ho hanyetsa le ho tšoarella;

(4) matla a phahameng, mocheso o potlakileng oa mocheso, ts'ireletso e ntle ea likarolo, e ka etsoa e le tšesaane haholo;

(5) aluminium alloy e boima bo bobebe, ductile ebile e bonolo ho bopeha, e loketseng ho netefatsa le ho ntlafatsa boleng ba lihlahisoa tse sebetsitsoeng;

(6) manganga ho mobu, ho le bonolo ho hloekisa.

Litšobotsi le ts'ebetsong ea aluminium alloy ea mohala oa mohala oa mohala:

5052 motsoako:

Ke ea al-mg series antirust aluminium alloy, e nang le ts'ireletso e ntle ea ts'enyeho, ts'ebeliso e ntle ea mocheso, ts'ebetso e ntle ea mocheso o tlase le matla a itekanetseng. Karolo ea mantlha ea alloying ea 5052 ke magnesium, e ke keng ea matlafatsoa kalafong ea mocheso, e na le polasetiki e ntle le ts'ebetso e phahameng. sekhahla sa ho thatafala.

Ho sebelisoa haholo ho ts'enyeho manganga, weldable, mahareng matla aluminium motsoako thepa e sebopeho; Mohlala, e sebediswa bakeng sa lihlahisoa tse nang le litlhoko tsa ponahalo e phahameng le e ntle weldability.Various mokelikeli le khase lik'hontheinara le likarolo tse ling tse nyenyane mojaro entsoe ke kotokaka tebileng; Hape hangata sebelisoa ka likoloi tsa sephethephethe, likepe tsa likarolo tsa tšepe, lisebelisoa, lebone la seterateng le rivet, lihlahisoa tsa lisebelisoa, khetla ea motlakase.

6013 motsoako:

Ke mofuta o mocha oa al-mg-si-cu aluminium alloy, haholo-holo e nang le magnesium, silicon, koporo, manganese le likarolo tse ling, tse nang le ts'ebetso e ntle e phethahetseng. 6013 e loketse lihlahisoa tse nang le litlhoko tse phahameng tsa matla, ho hanyetsa ts'enyeho le oxidation ea anodic. ts'ebetso ea 'mala;

Motsoako o na le lits'ebetso tse fapaneng mefuteng ea mohala oa mohala oa mohala, sepakapakeng, likepe, lipalangoang le kaho.Ha e sebelisoa bakeng sa motsoako oa aluminium oa khetla ea mohala oa mohala, mochini oa tlhahiso ke pele ho phunya poleiti ea mantlha, ebe ka ho sila, sandblasting , 'mala o koahelang kapa ho roala,' me qetellong e bentša, qetellong e etsa mokotlana o felletseng oa tšepe ea mohala oa thekeng.

6063 motsoako

Ke ea al-mg-si series alloy e phahameng ea aluminium alloy. lebelo extrusion sebopeho sa lifaele tse rarahaneng; Ts'ebetso e ntle ea khabiso, bokaholimo ba ts'ebetso bo hloekile haholo, 'me ho bonolo ho e tlotsa le mmala.

Ke motsoako o sebelisoang ka ho fetesisa letotong la al-mg-si, le sebelisoang khafetsa ho aheng thepa ea mokhabiso, aluminium bakeng sa bolulo ba mehala ea thekeng le likhomphutha, liphaephe tsa nosetso le lisebelisoa tsa extrusion bakeng sa fenishara, lipolanete, makoloi le terata.

6061 motsoako

Ke ea al-mg-si alloy, e nang le magnesium le silicon e phahameng ho feta 6063 le koporo e nyane. Ka hona, matla a eona a phahame ho feta a 6063, empa kutlo e tima e boetse e phahame ho feta ea 6063. Moea Ho tima ho ke ke ha phethahala kamora extrusion, ka hona ho hloka kalafo ea tharollo le ho tima botsofe ho fumana matla a phahameng. Matla a phahameng, polasetiki e ntle le khanyetso e ntle ea ts'enyeho;

Haholo-holo, ha ho na khatello ea ts'enyeho ea ts'enyeho, e nang le ts'ehetso e ntle, ts'enyeho ea ts'enyeho le bokhoni ba ho sebetsa bo batang. Mmala o khabisitsoeng, o bonolo ho o apesa, o loketse thepa ea mokhabiso oa moaho le thepa ea moaho ka kakaretso.

E sebelisetsoa ho hloka matla a itseng, ho ts'ehetsa le ho hanela ho bola ha mefuta eohle ea liindasteri, joalo ka likarolo tsa lifofane, likarolo tsa kh'amera, coupler, lisebelisoa tsa sekepe le lisebelisoa tsa thepa, lisebelisoa tsa elektroniki le lisebelisoa, mekhabiso kapa lisebelisoa tse fapaneng, lihokelo, hlooho, hlooho , mariki, piston ea haeteroliki, likarolo tsa piston, lisebelisoa tsa motlakase, li-valve le valve ke mofuta oa tšebeliso e pharalletseng, e ts'episang alloy.

Ka ntlafatso ea mohopolo oa ts'ebeliso, boemo ba kananelo le mahlale a indasteri, lisebelisoa tsa aluminium tsa mehala ea mehala li tla ntlafatsoa khafetsa, 'me lisebelisoa tsa aluminium tsa liselefouno tsa nako e tlang li kanna tsa hlolla le ho feta,' me tsa etsetsoa motho ka mong.