Aluminium extrusion heatsinks

Aluminium e atolositsoeng ke e 'ngoe ea litsela tse tsebahalang haholo le tse sa bitseng chelete e ngata tsa ho etsa li-radiator. Li-radiator tsa standard extrusion ke li-radiator tse sehiloeng le tse phethiloeng' me hangata li kenyelletsa lisebelisoa tsa ho kenya. E ka sebelisoa ho lisebelisoa tsa LED, IGBT le IC, hammoho le lipakete tse ling tse fapaneng tsa elektroniki.

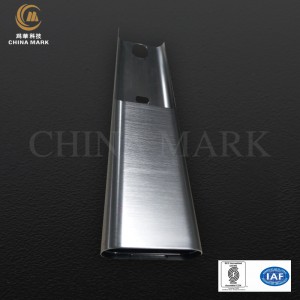

Radiator fin e na le bokhoni ba bohlokoa tlhahisong ea CNC 'me e ka fumaneha ho tsoa palo e kholo ea likarolo tsa aluminium extrusion le hlobo e seng e ntse e le sebopeho sa radiator.

Karolo ea sefapano ea radiator ea extrusion e rarahane haholo 'me thepa e sebelisitsoeng e senyeha habonolo. Likarolo tse ekelitsoeng li na le qetello e ntle ea bokaholimo' me li loketse tse ling mekhoa ea kalafo ea bokaholimo e kang ho tšela anodizing kapa electroplating.

Re sebelisa AL6063 aluminium alloy e nang le mocheso o phahameng oa mocheso, oo baetsi ba radiator ba bangata ba sa o sebeliseng hobane ke "fudge" mme ho thata ho e sebetsana ntle le moralo o motle oa tekheniki. 8: 1, ka hona e fana ka ts'ebetso e ntle ka ho fetesisa.

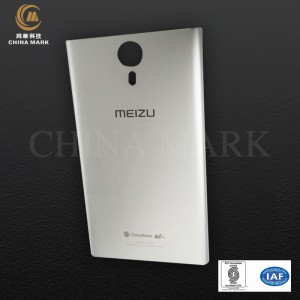

Likaroloana

Aluminium extrusions ke tharollo e bolokang chelete ho fetisisa bakeng sa likopo tse ngata tsa ho pholisa elektroniki

Bokhopo bo phahameng ba ts'ebetso e eketsehileng

E entsoe ka aluminium alloy 6063

Lifaele tsa extrusion li fumaneha ka kotloloho fin, STAR LED, le meralo e totobetseng ea LED, ho netefatsa ts'ebetso e phahameng ea ts'ebeliso e itseng ea mocheso

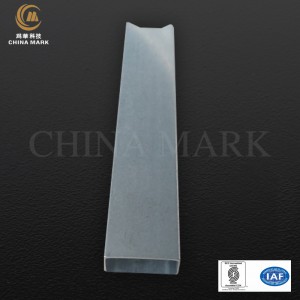

Tlhahiso ea radiator ea extrusion e tloaelehileng

Re ikemiselitse ho fana ka ts'ebeletso e ikhethang ea bareki tšimong e nyane ea radiator. Ka mechini ea rona ea boemo bo holimo ea CNC, re ka khaola, ra kolota le ho sebetsana le litlhoko tsohle tsa radiator ka nako e loketseng haholo.

Haeba u entse mapheo, re ka u thusa ho a etsa.Re na le lisebelisoa tsa sehlopha sa pele tsa extrusion, 'me re fetisitse tlhahlobo ea boleng bo felletseng ka nako e ts'oanang, re na le basebetsi ba maemo a pele ho netefatsa tsoelo-pele e ntle ea projeke ea hau; Re ka u fa lits'epe tse kopantsoeng tse hlokahalang, qetello ea bokaholimo le ts'ebetso ea bobeli Haeba sebopeho seo u se hlokang bakeng sa kopo ea hau se se lethathamong la rona, re ka sebetsa le uena ho rala li-extruders tse ikhethileng ho fihlela litlhoko tsa hau tse khethehileng. Iteanye le rona.