Aluminium extrusion ts'ebetso:

Ha e le hantle extrusion e qalile ka extrusion e entsoeng ka molamu oa aluminium, molamu oa aluminium o lokela ho futhumatsoa pele o eketsoa, ho futhumatsa melamu e metle ea aluminium sheng ingot e kentsoe moqomong oa extruder kahare, ebe e tsamaisoa ke molamu o matla oa haeteroliki oa extrusion, molamu bokapele ba molamu oa extrusion bo na le khatello, joalo ka mocheso o futhumetseng oa aluminium ka har'a dummy block tlasa khatello e matla e tsoang ho hlobo e nepahetseng ea hlobo ea extrusion, fumana sehlahisoa sa hoqetela.

Sebaka sa aluminium ha se na letho ka ts'ebetso ea extrusion. Aluminium bar bakeng sa extrusion e kanna ea ba e tiileng kapa e sekoti, hangata e le cylindrical, 'me bolelele ba eona bo khethoa ke li-spindles tsa extrusion.Aluminium mekoallo hangata e lahleloa, e meng e entsoe kapa e hatelloa.Hangata melamu e futhumetse ho isa likhatong tse 450 seboping se futhumatsang pele e romelloa, ka 10% e setseng ka har'a li-ingots.

Kemiso ea mekhoa ea extrusion:

1. Ho ea ka tataiso ea extrusion: pele extrusion, reverse extrusion, lateral extrusion

2. Ho ea ka litšobotsi tsa deformation: sefofane deformation extrusion axial symmetry deformation extrusion kakaretso ea mahlakore a mararo deformation extrusion

3. Ho ea ka mmuso oa setlolo: ha ho na lubrication extrusion lubrication extrusion e loketseng lubrication extrusion

Melemo ea ho sebetsana le extrusion:

1. Ntlafatsa bokhoni ba ho fetoha ha tšepe

Karolo ea extrusion ea aluminium e hloekileng e ka fihla ho 500, karo-karolelano ea extrusion ea koporo e hloekileng e ka fihla ho 400, 'me karo-karolelano ea tšepe e ka fihla ho 40-50.

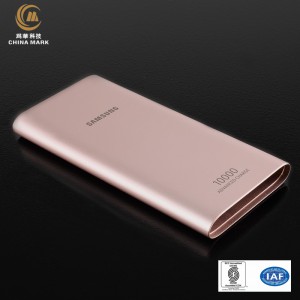

2. Lihlahisoa tsa extrusion li na le boleng bo phahameng bo felletseng

Ts'ebetso ea extrusion e ka ntlafatsa sebopeho sa microstructure le mochini oa thepa ea tšepe, haholo bakeng sa lits'epe tse ling tsa aluminium tse nang le phello ea extrusion, longitudinal (extrusion direction) thepa ea mochini oa lihlahisoa tse ntšitsoeng kamora ho tima le ho tsofala li phahame haholo ho feta lihlahisoa tse tšoanang tse hlahisoang ke mekhoa e meng ea ts'ebetso. .

3. Lihlahisoa tsa extrusion li na le mefuta e mengata

Ts'ebetso ea extrusion e ke ke ea hlahisa feela phala, molamu le terata e nang le sebopeho se bonolo sa karolo, empa hape e ka hlahisa likarolo tse tiileng le tse sekoti tse nang le sebopeho se rarahaneng haholo, le likarolo tsa likarolo tse fapaneng tse nang le phetoho butle-butle le phetoho e etsahalang butle butle lehlakoreng la bolelele ba karolo ea sehlahisoa.

Boholo ba litekanyo le bona bo pharalletse haholo, ho tloha ho li-tubes tse kholo haholo le li-profiles tse nang le likarolo tse nang le selikalikoe se ka ntle sa bophara ba 500-1000mm ho nyane haholo extrusions ka nepo e nang le likarolo tse boholo ba lithupa tsa mollo.