Lilemo tse 20 tsa boiphihlelo indastering e batang ea ho tapa / ea ho taka / e chesang ea aluminium, e shebaneng le ho buloa ha tšepe le ho betla / ho taka / ho betla / tlhahiso ea CNC le ts'ebetso ea lihlahisoa tsa aluminium, hlobo ea aluminium extrusion.

Aluminium extrusion bakeng sa mahlale le mahlale a China, e sebelisoang haholo, mekhahlelo e felletseng, boleng bo holimo, ts'ebeletso ea maemo a pele, tšusumetso ea extrusion aluminium e ka etsoa ho latela litlhoko tse fapaneng, amohela ho buisana;

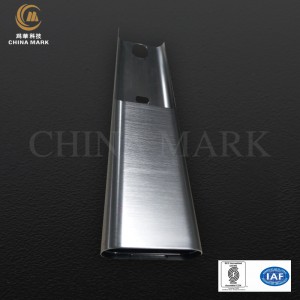

Aluminium extrusion lesela extrusion ts'ebetso

Mekhoa ea ts'ebetso:

1. Senya silinda ea ingot ho 380 ℃ - 420 ℃ ka mokhoa oa ho futhumatsa gradient ea 100 ℃ / 1 hora.

2. Ho ea ka leqephe la moralo oa ts'ebetso, khetha palo e loketseng ea ho futhumatsa sebōpi sa aluminium ho 480 ℃ - 520 ℃, lifaele tse ikhethileng tsa indasteri ho latela mocheso o boletsoeng.

3. Ho latela moralo oa ts'ebetso, khetha hlobo ho latela moralo, e futhumatse ho fihlela ho 460 ℃ - 500 ℃, 'me e futhumetse lihora tse 2--4.

4. Qala motlakase o pholileng oa extruder - enjene ea oli.

5. Ho ea ka tatellano e le 'ngoe ea moralo, khetha mosamo o khethehileng hore hlobo e kenngoe motheong oa hlobo,' me u notlele setsi sa hlobo sebakeng sa extrusion.

6. Notlela moropa o ts'oereng ebe o phahamisa bareng e futhumetseng ea aluminium ho ea boemong bo tsamaellaneng ba gallbladder ea thepa ka ho sebelisa rack.

7. Master cylinder pele extrusion

8. Lebelo la pele la ho tobetsa le lokela ho ba butle, 'me lebelo le mahareng le lokela ho fetoloa ho latela boleng ba bokaholimo ba boemo bo holimo.

9. Rekota nomoro ea hlobo, aluminium bar bar, khatello ea master silinda le lebelo le lahlehang ka botlalo ho rekoto ea mantlha.

Ii. Tsamaiso e hlokahalang

1. Mocheso oa ho futhumatsa molamu oa aluminium mochini ke: A flat die: 500 ℃ - 520 ℃ b. arola shoa: 480 ℃ - 500 ℃ c. thepa e khethehileng ea indasteri e etsoa ho latela litlhoko tse ikhethang tsa ts'ebetso.

2. Ts'ebetso ea ho futhumatsa hlobo: a. bataletseng shoa: 460 ℃ - 480 ℃ b. arola shoa: 460 ℃ - 500 ℃

3. Ho beha mocheso oa tube: 380 ℃ - 420 20 mocheso oa bokaholimo ba "ingot tube" ke 280 ℃ - 360 ℃

4. Thepa e ntšitsoeng e tlameha ho ba le bokaholimo bo boreleli, ha ho na maikutlo a letsoho bakeng sa ho its'oarella ha bolelele ba nako, lijo-thollo tse ntle esita le tse tsoang kantle, ha ho na lebanta le khanyang, mohala o motšo, lekhalo la sefofane lipakeng tsa lifofane tsa Yin le Yang, ho kheloha ha Angle, le Angle ea ho itšeha e lokela ho ba ea holimo boemo bo nepahetseng ho latela maemo a naha.

5.Khatello ea extrusion: ≤200㎏ / cm2

6 khatello ea senotlolo 120 6 / cm2 - 150㎏ / cm2.

7. Mocheso oa oli ea hydraulic ≤45 ℃

8. Boemo ba phallo ea profil bo laoloa ka kakaretso ka: 5 m / min -30 m / min

10. Nts'etso e ngoe le e ngoe ea melamu e 80 -100 e lokela ho sebelisa mosamo o khethehileng o hloekileng oa silindara ho hloekisa bile.

Tse tharo. Litaba tse hlokang tlhokomelo

1. Nakong ea extrusion, haeba lefu le hoketsoe, nako e shoang e ke ke ea feta metsotsoana e 5.

2. Ha u kenya hlobo, ela hloko polokeho 'me u thibele sekontiri hore se se ke sa thella' me sa robeha leoto.

3. Ha u tsoa, ho thibetsoe ka thata ho nyarela ka kotlolloho ka ntle.

4. Pele o hloma die, boemo ba setsi bo tlameha ho hlahlojoa mme molamu oa extrusion o lokela ho hokahanngoa. Mochini oa tlhahlobo o se nang mojaro o lokela ho tsamaisoa hang pele o qala mochini.

5. Hore na thempereichara ea molamu oa ho lekanya, hlobo le moqomo oa ingot e fihlella litlhokahalo.

6.3 - hlahloba boleng ba melamu e 5 hang.

Sheba mocheso oa oli khafetsa.

8. Hore na mochini o mong le o mong oa aluminium o tšoailoe ka nomoro ea sebopi le nomoro ea moputso.