Sebetsa ka ho nepahetseng machining e sebelisoa ho tlosa thepa e tala mosebetsing 'me e boloka mamello e haufi e phethela. Sena se thusa ho theha sehlahisoa se phethiloeng se phethahetseng Ka mantsoe a mang, e bonts'a ho bōptjoa ha litene tse kholo tsa thepa hore e be likarolo tse ling tsa konkreite. Ka tsela ena, li ka kopana le litlhaloso tse nepahetseng. Ts'ebetso ena e kenyelletsa ho itšeha, ho reteleha, ho sila le ho tjhesa machining. Hangata ka thuso ea lisebelisoa tsa CNC.

Ts'ebetso e nepahetseng ea boleng bo holimo e hloka bokhoni ba ho latela lipolane tse ikhethang tse hlahisoang ke CAD (moralo o thusang k'homphieutha) kapa mananeo a CAM (a thusang ka tlhahiso ea likhomphutha) joalo ka AutoCAD le TurboCAD. Lisebelisoa tsena li tlameha ho lateloa ka tieo ho netefatsa hore sehlahisoa se boloka bots'epehi Leha likhamphani tse sebetsang hantle haholo li sebelisa mofuta o mong oa lenaneo la CAD / CAM, hangata li sebelisa metako e huloang ka letsoho mohatong oa pele oa moralo.

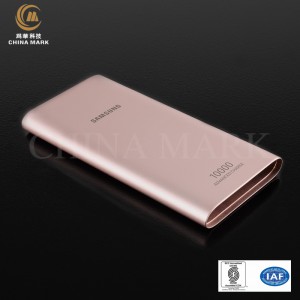

Ho tloha ka aluminium, koporo le tšepe ho isa ho tse sa tloaelehang le tsa bohlokoa (tse kang khauta, iridium le platinamo), mochini o tsoetseng pele oa CNC o ka etsa le meralo e rarahaneng ka ho fetesisa ho lisebelisoa tse ikhethang ka ho fetesisa. Lisebelisoa tse fapaneng tsa ho sebetsa ka nepo li tla sebelisoa. Motsoako o mong le o mong oa li-lathes, mechini ea ho sila, mechini ea ho cheka, lisakha le li-grinders li ka sebelisoa, mme ho ka sebelisoa liroboto tse lebelo haholo. Lisebelisoa tsa CNC li lumella litekanyo tse nepahetseng hore li lateloe nakong eohle ea sehlahisoa.

CNC ke eng?

Taolo ea lipalo tsa likhomphutha (CNC) e lumella mechini ho tsamaisoa le ho beoa leihlo ke taolo ea likhomphutha. Mechini e mengata ea CNC e pharalletse haholo - mechini e silang, li-welders, li-grinders, li-lathes, li-cutter tsa milling, lisepa tsa ho sila, mechini e otlang, mefuta e mengata ea lits'ebetso tse kholo tsa indasteri itšetleha ka theknoloji ea CNC ho hlahisa likarolo tse nepahetseng, tse ikhethileng.

Likhoutu tse ikhethileng tsa software (joalo ka khoutu ea NC le khoutu ea G kapa khoutu ea ISO) li ka sebetsoa ka CAM (machining e thusitsoeng ke khomphutha) le liphutheloana tsa software tsa CAD (komporo e thusang) ho khanna mechini ea CNC ho theha likarolo tse tharo ka kotloloho ho tsoa ho moenjineri moralo oa dijithale.

Menyetla ea CNC machining sebetsa ka ho nepahetseng

Mechini e nepahetseng ea CNC ke ts'ebetso e ntlafalitsoeng ea ts'ebetso ea ts'ebetso ea CNC ho isa ho tlhahiso ea bongata nakong ea prototyping, mechini ea CNC e lumella bahlahisi ho aha kapele meralo e sebetsang e ka sebelisoang ho lekoa.Haeba ho na le tlhokeho 'marakeng, machining ea CNC e ka lemoha kapele. Mohato o mong le o mong o fokotsa haholo nako ea ho fetoha, ho nolofalletsa k'hamphani ho fokotsa haholo litšenyehelo tsa menyetla e lahlehileng.

Tšebeletso ea CNC machining

Ts'ebetso ea likhomphutha ea likhomphutha (CNC) e tsejoang hape e le ho sila ha CNC) ke ts'ebetso ea ho etsa ts'ebetso ea sesebelisoa sa mochini ka litaelo tse hlophisitsoeng hantle tsa khomphutha.CNC machining e ile ea fetoha indasteri tekanyetso ho elella lilemong tsa bo-1960 mme e ntse e le mokhoa o ratoang oa machining. Mechini le lisebelisoa tse ka laoloang ke ts'ebetso ea CNC li kenyelletsa li-lathes, li-grinders le mechini e silang.

Milling ea CNC e khona ho boloka mamello e thata haholo ea jiometri maemong a mangata a litšobotsi tsa bohlokoa tsa karolo eo (joalo ka bophara, boemo ba 'nete, moeli le ho hlophiseha).

Ho tloha tlhahiso ea makoloi ho isa likarolong tsa lifofane le lisebelisoa tsa elektronike tsa indasteri, indasteri e ngoe le e ngoe eo u ka e nahanang e kenyelletsa ts'ebetso e nepahetseng ea CNC, ka hona, haeba u tloaelane le projeke e kenyelletsang likarolo, ho na le monyetla o motle oa hore e fetile sebetsa ka ho nepahetseng machining.

Ka litšenyehelo tse theko e tlase tsa lisebelisoa le bokhoni ba ho theha likarolo tse rarahaneng, CNC machining sebetsa ka ho nepahetseng ke tharollo e tsebahalang bakeng sa merero ho tloha ho prototyping ho isa ho tlhahiso e kholo ea e ikhethang likarolo tse nepahetseng.