Moelelo oa matšoao a electroforming:

Letšoao la electroforming hangata le bolela letšoao le entsoeng ka nickel, ebe le koahetsoe ka silevera kapa khauta, kapa le koahetsoeng ka koporo. Hona joale e nkoa e le letšoao le phahameng ka ho fetisisa.Matšoao a electroforming a arotsoe ka lihlopha tse 'nè, lera le ka tlaase ke mokoallo oa sekhomaretsi, karolo ea bobeli ke sekhomaretsi, karolo ea boraro ke lipontšo tsa electroforming tseo re li sebelisang, le karolo ea bone. e entsoe ka filimi e sireletsang e pepeneneng holim'a matšoao a electroforming. Bokaholimo bo ka ba matte kapa bo benya, 'me bokaholimo bo ka siloa.

Likarolo tsa matšoao a electroforming:

1. Tekanyo ea tšilafalo ea tikoloho e bobebe, ha ho na kutu e hlokahalang, kahoo e ke ke ea baka tšilafalo ea etching.

2. Mokhoa ona o bonolo. Matšoao a electroforming ha a hloke hlobo leha e le efe, kahoo ha ho hlokahale hore u tšoenyehe ka ho lefa litšenyehelo tse phahameng tsa hlobo ho etsa letšoao. Mesebetsi eohle ea mesebetsi ea matsoho e ka phethoa ka filimi e bonolo, e phahameng, e khanyang. Matšoao a electroforming. Boloka nako, mathata le chelete.

3. Nako ea tlhahiso ea mohlala e potlakile, ka kakaretso ke matsatsi a 1-2 feela ho qeta sampuli

4. Thepa e bonolo, ts'ebetso eohle ea tlhahiso e hloka feela ho sebelisa sethala sa khatiso sa skrine, lebokose la ho baka, mochine oa ho pepeseha, tanka ea electroplating le lisebelisoa tse ling tsa motheo.

5. Lisebelisoa tse fokolang, hobane ha ho hlokahale hore ho be le sesebelisoa leha e le sefe se eketsehileng, kahoo boholo bo lekanang ba letšoao la tšepe, thepa e jeoang ke 1/7 e ka tlaase ho pontšo e entsoeng ke mokhoa oa etching oa concave-convex.

Litlhoko tsa bophahamo ba matšoao a electroforming:

Bophahamo bo loketseng ba lets'oao la nickel ea electroformed hangata bo ka tlase ho 3mm, 'me karolo e phahamisitsoeng e pakeng tsa 0.4 le 0.7mm. Ka nako e ts'oanang, bophahamo kapa botebo ba fonte ha boa lokela ho feta 0.3mm, e le hore letšoao le tla ba le letle haholoanyane.

Mokhoa oa ho kenya matšoao a electroforming:

Ka kakaretso sebelisa sekhomaretsi se matla bakeng sa ho peista, khanyetso e matla ea leholimo, e matla haholo ebile e tšoarella.

Sebaka sa ts'ebeliso ea matšoao a electroforming:

E sebelisoa ka kakaretso lisebelisoa tse fapaneng tsa ntlo, thepa ea ka tlung, joalo ka logo ea mochini o hlatsoang, logo ea sehatsetsi, logo ea ontong, logo ea onto ea microwave, logo ea moea, mochini o hlatsoang lijana, lets'oao la moetsi oa bohobe, lets'oao la khomphutha, lets'oao la molumo, logo ea botlolo ea litlolo, logo ea botlolo ea veine, joalo-joalo , Tšebeliso ea matšoao a electroforming e tla etsa hore lihlahisoa tsa hau li be le maemo a holimo le a hlollang, 'me litšenyehelo li tla tsebahala. Hobane matšoao a electroforming a na le khanya e matla, 'me a tla bonahatsa liphello tse fapaneng tsa khanya ho latela li-angles tse fapaneng.

Ho aroloa ha matšoao a electroforming:

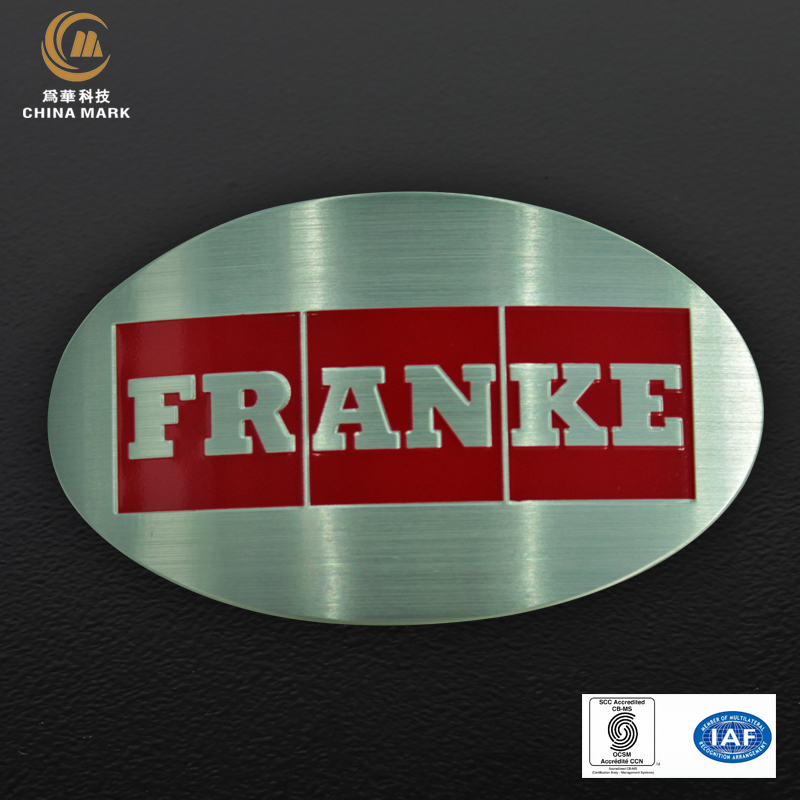

Ho na le mefuta e 'meli e meholo ea lipontšo tsa electroforming: electroforming e teteaneng le electroforming e nyenyane (eo hape e bitsoang nickel plate). Bophelong ba letsatsi le letsatsi, tšebeliso ea matšoao a nickel a electroformed e tloaelehile haholo. Electroformed nickel label e entsoe ka nickel sheet casting le plating, botenya bo pakeng tsa 0.03mm ~ 0.1mm (sena se ipapisitse le litlhoko tsa moreki), bokaholimo bo boreleli, ha bo na sekoli, 'me ho nepahala ho nepahetse. E khomaretsoe ka thata ka sekhomaretsi se matla sa 3M. Ho bonolo haholo.

Lisebelisoa tsa lets'oao la electroforming, sekhomaretsi le phello ea bokaholimo:

Lisebelisoa tse ka sehloohong ke nickel, koporo, khauta le chromium; li-adhesives tse sebelisoang hangata ke 3M 7533/3M 9448/3M 467/ 3M468 / hot melt sekhomaretsi, joalo-joalo; ho na le mebala e mengata e fumanehang, haholo-holo ho latela litlhoko tsa bareki, hangata silevera / e ntšo / khauta e mosehla / khauta ea rose / khauta ea champagne; litlamorao tse tloaelehileng tsa bokaholimo ke phello e khanyang ea sefahleho, phello ea brushing, phello ea sandblasting, phello ea reticulate le phello ea CD.

mokhoa oa tlhahiso ea lipontšo tsa electroforming:

Ts'ebetso ea lipontšo tsa electroforming e batla e le bonolo, haholo-holo e hlahisoang ke electroforming, ntle le hlobo leha e le efe, le filimi e le 'ngoe feela ts'ebetsong eohle ea tlhahiso. Boloka chelete le nako. Kamora hore karolo ya tlhahiso e fumane odara, hangata e ka hlahisa disampole ka letsatsi le le leng mme ya hlahisa dihlahiswa matsatsing a mmalwa. Ts'ebetso e hakanyetsoang: ho taka-filimi e hlahisoang-electroforming-color plating-film application-glue application-slitting-packaging-shipment.