Sebetsa ka ho nepahetseng machining Ho na le mefuta e mengata ea mochini o nepahetseng oa machining, ho kenyelletsa le ho sila, ho fetola le ho tjha machining. Ho sebetsa ka nepo kajeno ho laoloa ke taolo ea linomoro tsa khomphutha (CNC).

Ts'ebetso e atlehileng ea ts'ebetso e nepahetseng e hloka bokhoni ba ho latela lipolane tse ikhethileng tse ntlafalitsoeng ke moralo o thusang k'homphieutha (CAD) kapa mananeo a thuso ea khomphutha (CAM) .Theknoloji ena ea machining ea CNC e ka theha lichate tsa 3D kapa Litsela tsa ho hlahisa mechini, lintho kapa lisebelisoa. e tlameha ho raloa ho netefatsa boleng le katleho.

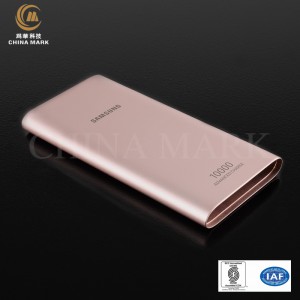

Mechini e nepahetseng e ka sebelisa lisebelisoa tse fapaneng, joalo ka boronse, khalase, graphite, polasetiki, tšepe le lisebelisoa tse ling.Ho latela boholo ba projeke le lisebelisoa tse amehang, ho tla sebelisoa lisebelisoa le mekhoa e fapaneng ea ho sebetsa ka nepo. Mahlale a nepahetseng a tlameha ho ba le boiphihlelo le boiphihlelo lits'ebetsong le lisebelisoa tse fapaneng Ba ka sebelisa motsoako o fe kapa o fe oa mechini ea ho cheka, mechini ea ho sila, lithupa, mechini e silang, lisakha esita le liroboto tse lebelo haholo ho etsa mosebetsi.

Thepa sebelisoa ka CNC machining:

Motsoako oa titanium (Ti - 6 al4v)

Metal Matrix likarolo tsa MMC (AMC225xe)

Special Steels (300 m, Maraging 300-350, 15 cdv6, 17-4 PH le tse ling)

Lisebelisoa tsa aluminium (2014, 2024, 6082, 7050, 7075 le tse ling), tšepe le Koporo

Superalloys (Inconel 625 le 718)

Mefuta ea lihlahisoa tse nepahetseng:

1. Mohlala le moralo o hlophisitsoeng

2. Lihlahisoa tsa elektroniki

3. Kalafo ea nako e le 'ngoe le e sa keneng

4, likhokahano tsa mehala,

5. Liindasteri le OEM

6. Bracket ea ho hloa, sesebelisoa se tsitsitseng, karolo e nepahetseng, khetla le motsoako, strut le karolo ea sebopeho ke lihlahisoa tsohle tse tloaelehileng tse hlahisoang ke ts'ebetso ea machining ea CNC.

About sebetsa ka ho nepahetseng CNC machining tšebeletso ea rona

Melemo ea mantlha ea ts'ebetso e nepahetseng ea CNC e kenyelletsa bokhoni ba ho hlahisa likarolo tse rarahaneng ka ho nepahala ho holimo ha o ntse o boloka litšenyehelo tse tlase tsa tlhahiso le ho kenya

Mechini ea CNC ke theknoloji e tšepahalang le e ntlafalitsoeng ka botlalo e felisang monyetla oa liphoso tsa batho mme ka hona e thusa ho ntlafatsa ho nepahala ka kakaretso.Ho ekelletsa moo, ka ho lokolla nako bakeng sa baetsi nakong ea tlhahiso, tlhokomelo e ka shebana le netefatso ea boleng le ho fana ka tlhokomelo ea projeke, eo E thusa ho netefatsa hore litlhoko tse qaqileng tsa ts'ebetso ea tlhahiso lia fihlelleha.

Mabapi le phokotso ea litšenyehelo, machining ea CNC ha e fokotse litšenyehelo feela ka ho fokotsa tlhoko ea barekisi ba nang le boiphihlelo, empa hape e fokotsa palo e felletseng ea lisebelisoa tse senyehileng.

Feletseng sebetsa ka ho nepahetseng machining CNC

Re fana ka lits'ebeletso tse felletseng tsa machining tsa CNC bakeng sa leloala la hau le nepahetseng la mochini, li-lathes, ho teba ha mochini, ho cheka ka tsela e nyane le litlhoko tse akaretsang.Lefapha la boenjineri le sebelisa moralo oa morao-rao oa CAD / CAM le theknoloji ho sebetsa 'moho le bareki ba rona.

Moralo o thusitsoeng ke khomphutha le tlhahiso

Re lula re ntlafatsa le ho tsetela ho mahlale a rona le lisebelisoa ho thusa baenjiniere ba rona ho rala mosebetsi o rarahaneng ho fihlela litlhoko tse hlokoang haholo. Baenjiniere ba rona ba na le tharollo ea 3D le CAD / CAM tse re nolofalletsang ho fana ka liphetho tse nepahetseng.

U ka itšetleha ka boleng

Re ananela boleng, re ikemiselitse ho fana ka lihlahisoa le litšebeletso tse fihlellang kapa tse fetang litebello tsa bareki Re lula re batla mekhoa ea ho ntlafatsa tsamaiso ea rona ea taolo ea boleng.

Leha boholo CNC machining sebetsa ka ho nepahetseng e loketse ho sebetsana le tšepe, lisebelisoa tsena li tenyetseha haholo 'me li ka sebelisoa ho hlahisa tse ikhethileng likarolo tse nepahetseng bakeng sa liindasteri tse fapaneng.Re amohela re botse