Top Suppliers China Aluminium Extruded Aluminum Enclosure Box Charging Pile for New Energy Auto

Attaining consumer satisfaction is our company’s purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Top Suppliers China Aluminium Extruded Aluminum Enclosure Box Charging Pile for New Energy Auto, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

Attaining consumer satisfaction is our company’s purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Aluminum, China Aluminium, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we’ll prove our capability. With your kind help, we believe that we can create a bright future with you together.

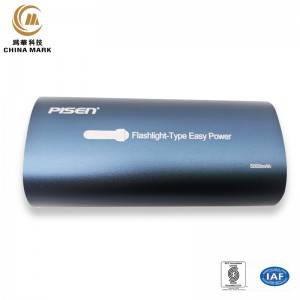

Extruded Aluminum Enclosure

| Name | Aluminum extrusion charge pal |

| Processing | Aluminum extrusion +CNC+Grounding+Sandblasting/Anodized+Laser engraving+Full inspection+Package |

| Application | Charge pal |

| Type | Aluminum extrusion profiles |

Extruded aluminum enclosure can be used independently or surface-mounted, and these all-metal housings provide the ideal framework to create extremely strong yet lightweight housings that are ideal for electronics industry OEM housing applications.

The aluminum extrusion charge pal is very useful because it can be easily installed.

Features:

1. High stability

2. Good heat dissipation

3. High quality appearance

4, waterproof, moistureproof

5. Anodic oxidation treatment is adopted

Process:

1. CNC machining

Use the required machining method to process the shell, saving you time and money.Ensure accuracy, no scrap, short lead time.

2. Digital printing

Enhance product quality and print high quality graphics directly on the extruded case to impress your customers.

Custom extruded aluminum case with variable length

WEIHUA — Aluminum extrusion manufacturers, we are a high-quality shell solution enterprise;We can customize the aluminum extruded box to meet your special requirements such as design and size.Note: extruded aluminum profiles can be provided with special lengths upon request.

If necessary, we can process and customize the aluminum extruded case according to your needs.

You may also like:aluminum box extrusion-OPPO outer case;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:6063 round bar Ø100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA