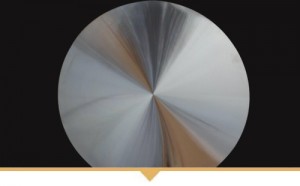

Trending Products 86% Anodized High Reflectivity Polished Mirrored Aluminum Plate Reflector

Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Trending Products 86% Anodized High Reflectivity Polished Mirrored Aluminum Plate Reflector, We are going to make increased attempts to aid domestic and international buyers, and generate the mutual benefit and win-win partnership between us. we are eagerly waiting for your sincerely cooperation.

Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Aluminum Metal Sticker, Metal Stickers For Sound, Shiny Gold Metal Label Sticker, We always insist on the management tenet of “Quality is first, Technology is basis, Honesty and Innovation”.We’ve been able to develop new products and solutions continuously to a higher level to satisfy different needs of customers.

Metal name plates engraved

| Material | Usually use the Alum plate or copper under 1mm THK |

| Process | - Alum cut+stamp+CD brush+bending+anodize+high gloss - by stamping or cold pressing technique, - To get each kind of concentric grain effect by the hi-precision full auto CD grain machine, - To achieve each colorful part by further combining with the anodizing or galvanizing process; |

| Application | Nameplate of speaker |

| NW | 34g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology (custom metal nameplates manufacturers) is a professional and comprehensive brand nameplate, metal lithography offset printing, screen printing, stamping and other comprehensive manufacturers.Products are widely used in: loudspeaker, packaging gift box, craft gift factory, machinery manufacturing, electronics, hardware and electrical appliances, etc.Material: brass, aluminum, antique brass, stainless steel, etc.Process: carving, stamping, drawing, etching, etc.;Welcome to consult personalized metal name plates customization!

The method of distinguishing good and bad metal nameplate

1. Materials are preferred;

2. Technological innovation;

3.the paint of the face is elegant, because smooth, once there is a little uneven will have convex concave pits out, the feeling on the vision is very uneven.

4.silk screen printing process and different color techniques are not the same,

5. Finally, whether the handle of the facial paint is smooth or not.

The above master these methods to be able to determine the best metal nameplate.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:All series of alum plate

Step 2:Auto cut, by adjusting the parameters per the engineering dwg

Step 3:Neat & clean stamping workshop

Step 4:Machine the CD grain

Step 7:Professional inspectors and packaging workers

Step 5:Excellent visual effect to show the high-end level

Step 6:Auto line of anodic oxide process

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA