Well-designed China High-Quality Custom Printing Aluminum Nameplate, Stainless Steel Accessories For TV

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for Well-designed China High-Quality Custom Printing Aluminum Nameplate, Stainless Steel Accessories For TV, Teamwork is encouraged at all levels with regular campaigns. Our research crew experiments on various developments inside the industry for improvement in the merchandise.

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for 304 SUS Logo, China Plating Metal Part, Custom Metal Badge, Stainless Steel Part For TV, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have now gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Stamped metal logo

| Material | zinc alloy, alum alloy |

| Process | - Zinc+dissolve+diecast+galvanized+ovening - by die-cast by die-cast machine- further combined with polishing/galvanizing or painting process to achieve the parts. |

| Application | Nameplate for TV |

| NW | 120g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology professional stamping metal nameplate (stainless steel plate) manufacturers;Surface style effect: can do matte surface, drawing, mesh, twill, horizontal, CD, corrosion, mirror, dumb surface, gold, concave and convex three-dimensional, oil injection.Welcome to consult understanding!

Stamped metal nameplate meaning

Stamping badges are generally made of metal materials using metal stamping and a variety of other badge production process combined into the high-end badge, also known as stamping badges or metal stamping badges.Because it can better deduce the corporate strategic brand image, set up the purpose of the association group industry, so the stamping badge is widely loved.

1, stamping badges mainly use materials such as copper, stainless steel, aluminum, zinc gold, alloy and other common materials, but also some high-grade stamping badges use some precious metal materials such as gold and silver, this precious metal stamping badges has a very high value of collection and investment, is in recent years favored by the investment and collection of varieties.

2. The main shapes of stamping badges are long rectangles, squares, circles, ellipses and special shapes.In view of the stamping badge made and designed by haixin badge, it is mainly circular stamping badge.

3. Design of stamping badges

Stamping badges in the design is mostly based on the enterprise or the company’s trademark LOGO LOGO as the leading design concept, but also can be designed for the double-sided content.According to their preferences for a variety of personal stamping badge design.

4. Features of stamping badges

Company badges are mainly to promote the image logo;Industry associations focus on the theme of leading activities.In addition, some stamping badges made of precious metals such as gold and silver have the value of investment and collection. For example, some financial products of Banks, Olympic badges and expo badges are all kinds of products containing the value of investment and collection.

5. Applicability of stamping badges

Stamping badges have a wide range of applicability, from publicity, corporate logo, activity theme to investment collection, etc., widely used in major groups, enterprises and institutions, party, government and military organs, industry associations, volunteer groups and other symbolic large-scale activities

6. Value of stamping badges

Stamping badge has a great value, it deduces the strategic brand image of the enterprise, set up the purpose of the association group industry, etc., in recent years, some precious metals such as gold badge and silver badge stamping badge as its investment and collection value is also increasingly prominent.

7. Packaging of stamping badges

The stamping badge contains two kinds of ordinary packaging and noble packaging, which depends on the customer’s requirements.Some precious metal stamping badges we recommend the use of high – quality packaging.

You may also like:nameplate for wardrobe;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

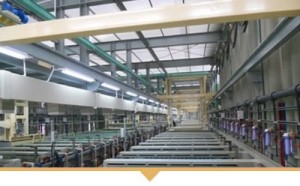

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA