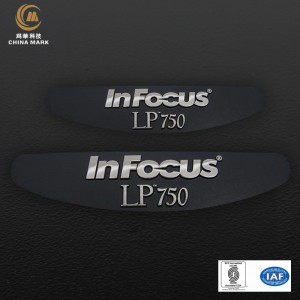

Wholesale ODM China Metal Nameplate Office Sign, Embossed metal name plates,Black Anodized Nameplate

With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for Wholesale ODM China Metal Nameplate Office Sign, Embossed metal name plates,Black Anodized Nameplate, “Making the Solutions of Large Quality” could be the everlasting goal of our enterprise. We make unremitting attempts to recognize the objective of “We Will Always Preserve in Pace while using the Time”.

With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for Anodized Aluminum Labels, Anodized Aluminum Metal Nameplates, China Digital device Plate and Nameplate price, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best items with lowest price. We’ve been making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We’ll always be your first choice. Trust us, you will never lose heart.

Embossed metal name plates

| Material | usually use the annealed alum |

| Process | -Alum cut+forge+stamping+anodize+brush+tool opening-to get every kind of LOGO-by cold forging process,-further combined with painting or anodizing,-and using diamond tools to get the carving finish or CD grain. , |

| Application | Nameplate for UAV |

| NW | 15g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Embossed metal nameplate, China custom nameplate, specially for enterprises/groups/activities customized stainless steel nameplate, brass nameplate engraved aluminum nameplate, metal nameplate and other more than ten years of experience, making goods fast, cost-effective;Welcome to consult!

Usage of aluminum nameplate:

With aluminum material production molding brand products collectively referred to as aluminum nameplate, in fact, aluminum nameplate processing technology is very much, different processes produced by the aluminum signage products are also different.

How to choose the ideal process effect needs to be decided according to the actual use, aluminum signage is mainly used to identify, publicize, establish and maintain the authority and reputation of the product, but also has the function of decorating and beautifying the goods.

Therefore, as a special mark to distinguish different product images, we cannot ignore the choice of production process.

I. use of aluminum nameplate:

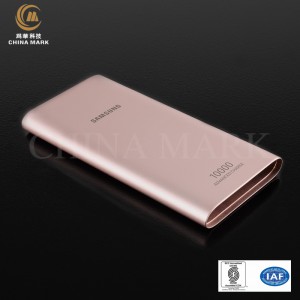

1. High-gloss wiredrawing aluminum plate has twill, arc, straight, CD, solar grain and other texture, it seems to have more characteristics.Applicable to furniture, office supplies, electronics, DVD, TV, computer, cabinet, electrical appliances, LCD, navigation, security door, kitchen utensils, bathroom, audio, wine box, tea, moon cake, gift box.

2. Plane printing and corroded aluminum plates are diversified in color addition and easy to be colored.Applicable to machinery, equipment, electrical control case, case, facilities, uav.

3. Luminous and reflective aluminum signs have warning, guiding and indicating functions.Use and road signs, community guide signs, road signs, door Numbers.

Ii. Process selection of aluminum nameplate:

Common production processes are: stamping, concave-convex, printing, corrosion, carving, polishing, electroplating, spraying.

You may also like:computer nameplate;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:Alum plate

Step 2:Laser cut according to engineering dwg

Step 3:Air-driven punching machine

Step 4:Forging device

Step 7:Exquisite nameplate

Step 5:Auto line of anodic oxide processing

Step 8:Professional inspectors and packaging workers

Step 6:Auto oil-dripping machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA