Wholesale OEM/ODM China High Quality Custom Aluminum Die Casting Heatsink

Always customer-oriented, and it’s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Wholesale OEM/ODM China High Quality Custom Aluminum Die Casting Heatsink, Inside our initiatives, we already have a lot of shops in China and our solutions have won praise from buyers all over the world. Welcome new and outdated buyers to contact us to the long run long lasting business relationships.

Always customer-oriented, and it’s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Aluminium Heat Sinks Manufacturer, China Casting, Die Casting Heatsink, High-performance heat sinks produced from die-cast, To create more creative products and solutions, maintain high-quality goods and update not only our goods but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer you and to grow stronger together. To be the real winner, starts here!

Custom metal nameplate

| Material | zinc alloy, alum alloy |

| Process | - Zinc alloy+dissolve-+diecast - by die-cast by die-cast machine - further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for headlight |

| NW | 180g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Zinc-alloy metal nameplate find weihua technology (name plate maker), specializing in the production of various metal signs, high quality, fine technology, sample making speed, support customer customization, product variety diversification, quality after-sales service

Aluminum alloy metal nameplate manufacturing process

In our normal life in many car headlights, furniture and luggage will see aluminum alloy metal nameplate figure above, it is common used in our daily life furniture, cases, bags, and indicates the product of a kind of alloy, road, car aluminum alloy panels for optimal performance, the advantages of light quality, rich in natural resources are widely used, aluminum alloy metal nameplate production process is what?

Production process of aluminum alloy nameplate:

1, machine molding

Aluminum alloy after stamping, cutting, concave and convex and die-casting and other technological stages after the processing of the receiver spray paint, make its installation size uniform scale and can be mass production, the instrument spray paint panel processing on the size requirements are more strict, need experienced pliers, milling workers, conditional can use CNC drilling machine.

2, in addition to the oil

Lu: su signs in order to make the surface of aluminum plate printing paint has a certain affinity, to remove the plate name of the oil, general packaging oil can be wiped off with fine soft sawdust, and then use inorganic solvents to oil;Oil stains in machining can be removed by inorganic solvent or alkaline solution.

3, polishing

Aluminum alloy sign production plate surface has scratches, should first scratch a layer of putty, make it smooth, and according to customer requirements screening is mechanical polishing, chemical polishing, or electrochemical polishing, specific visit other relevant information.

4, spray paint

Due to the poor combination of aluminum and finish paint, printing ink, before acrylic spraying finish paint, it is necessary to spray a layer of about 0.01mm thick epoxy zinc yellow primer, according to the customer’s requirements, coating with color of amino or acrylic paint.

5. Screen printing

All requirements of aluminum alloy plate panel is: the position of the text and text is accurate and clear, the word line edge is the same, the ink is firm, the requirement is not high brush brush coating, paint can choose H type water-soluble acrylic paint or amino paint.

Aluminum alloy signage can not only improve the role of the product brand can also be made into a sign has the role of identification, guidance, its aluminum alloy role also makes aluminum signage has the function of night reflection and luminous prompt, for our life has brought great convenience.

Aluminum alloy metal nameplate because the plate is heavier, easy to knock against each other, can be placed in the product without the old paper to protect its inside.

You may also like:nameplate for induction cooker;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

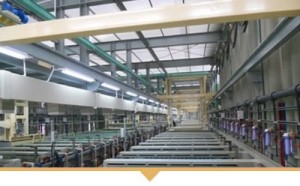

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA