Wholesale Price China Painted Plastic - Powder coating spray painting,PVD coating companies | CHINA MARK – Weihua

Wholesale Price China Painted Plastic - Powder coating spray painting,PVD coating companies | CHINA MARK – Weihua Detail:

Powder coating spray painting,PVD coating companies

| Material | ABS |

| Process | -Material prepare+moulding+deburr+grinding+galvanizing+ovening |

| Application | Panel of toy |

| NW | 25g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

PVD coating – professional coating manufacturers;Powder coating, high lubrication, oxidation temperature, vacuum coating,PVD coating company, low friction coefficient, improve the surface hardness;Exquisite workmanship, welcome to inquire ~

PVD is what?Solutions to questions related to vacuum plating technology for vacuum plating process:

Characteristics of PVD: PVD technology appears in the preparation of films with high hardness, low friction coefficient, good wear resistance and chemical stability.

Overview of PVD: PVD is also known as rational vapor deposition, refers to the use of physical processes to achieve material transfer, the transfer of atoms or molecules from the source to the substrate surface process.

Application of PVD: up to now, physical vapor deposition technology can not only deposit metal film, alloy film, but also can deposit compound, ceramic, semiconductor, polymer film, etc.

PVD coating technology is used to plating the film layer, with high hardness, high wear resistance (low friction coefficient), good corrosion resistance and chemical stability, the film life is longer;At the same time, the film layer can greatly improve the decorative performance of the workpiece.

PVD coating technology is an environmentally friendly surface treatment method that can truly obtain micron level coating with no pollution. It can prepare various single metal films (such as aluminum, titanium, zirconium, chromium, etc.), nitride films (TiN[titanium], ZrN [zirconium], CrN, TiAlN), carbide films (TiC, TiCN), and oxide films (such as TiO, etc.).

PVD coating technology is an environmentally friendly surface treatment method that can truly obtain micron level coating with no pollution. It can prepare various single metal films (such as aluminum, titanium, zirconium, chromium, etc.), nitride films (TiN[titanium], ZrN [zirconium], CrN, TiAlN), carbide films (TiC, TiCN), and oxide films (such as TiO, etc.).

Although the use of PVD coating technology can be plated out of high quality film layer, but the cost of PVD coating process is actually not high, it is a very cost-effective surface treatment method, so in recent years, PVD coating technology has developed very fast.PVD coating has become the development direction of surface treatment in hardware industry.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

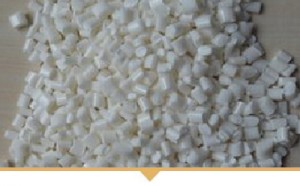

Step 1:ABS resin

Step 2:Molding machine

Step 3:Hi-precision tooling

Step 4:Galvanizing line

Step 7:Accessory for splendid toy

Step 5:Industry oven

Step 6:Full check lines

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for Wholesale Price China Painted Plastic - Powder coating spray painting,PVD coating companies | CHINA MARK – Weihua , The product will supply to all over the world, such as: Finland, Azerbaijan, Paris, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.