Inkqubo ye-Aluminium extrusion:

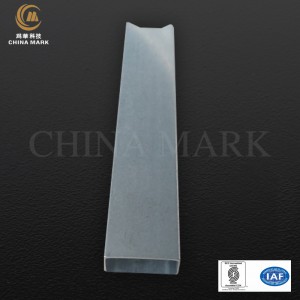

Okwenziweyo extrusion kuqalwe nge-extrusion cast kwi-aluminium rod, i-aluminium yokuphosa intonga kufuneka ifudunyezwe ngaphambi kokuba i-extrusion iyenze ithambe, ukufudumeza intonga elungileyo ye-aluminium yokufaka i-sheng ingot ibekwe kumgqomo wangaphandle ngaphakathi, emva koko iqhutywa ngamandla amakhulu e-hydraulic extrusion rod, i isiphelo sangaphambili sentonga ye-extrusion ine-pad yoxinzelelo, eshushu evuthayo i-aluminium alloy kwindawo yedummy phantsi koxinzelelo olomeleleyo oluvela ekubumbeni ngokuchanekileyo ekubumbeni i-extrusion, fumana imveliso yokugqibela.

Ibha ye-aluminium ayinanto kwinkqubo yokukhutshwa. Ibha yealuminium yokuqengqeleka inokuba yomelele okanye ingenamngxunya, ihlala ine-cylindrical, kwaye ubude bayo buchazwe zii-extrusion spindles.Imivalo yeAluminiyam ihlala iphoselwa, ezinye ziyenziwa okanye zicinezelwe.Ihlala yenziwe ngokusaha imivalo yealuminiyam enealloy efanelekileyo.Iirandi zihlala zifudunyezwa ukuya kuma-450 degrees kwiziko lokufudumeza ngaphambi kokuba lithunyelwe kwifom, malunga ne-10% eseleyo kwii-ingots.

Ukwahlulahlulwa kweendlela zokukhupha:

1. Ngokwale ndlela yokuya ngaphandle: phambili extrusion, ukubuyisela umva extrusion, lateral extrusion

2. Ngokutsho kweempawu deformation: moya deformation extrusion yezihlunu symmetry deformation extrusion ngokubanzi macala amathathu deformation extrusion

3. Ngokombuso we-lubrication: akukho lubrication extrusion i-extrusion efanelekileyo i-lubrication extrusion

Izinto eziluncedo ekusebenziseni i-extrusion:

1. Ukuphucula amandla deformation yesinyithi

Umlinganiso we-aluminium esulungekileyo unokufikelela kwi-500, umlinganiso we-extrusion wobhedu ococekileyo unokufikelela kuma-400, kwaye umlinganiso wesinyithi unokufikelela kuma-40-50.

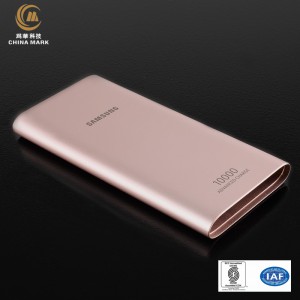

2. Iimveliso ze-extrusion zinomgangatho ophezulu obanzi

Isiphene sangaphandle sinokuphucula ubume bemicro kunye neepropathi zoomatshini bezinto zesinyithi, ngakumbi ezinye ialuminiyamu ezineziphumo ze-extrusion, longitudinal (ulwalathiso lwe-extrusion) iipropathi zoomatshini zeemveliso ezikhutshiweyo emva kokucima kunye nokuguga ziphezulu kakhulu kuneemveliso ezifanayo eziveliswa zezinye iindlela zokulungisa .

3. Iimveliso ze-extrusion zinoluhlu olubanzi

Ukulungiswa kwe-extrusion akunakuvelisa kuphela umbhobho, intonga kunye nocingo olunemilo elula, kodwa inokuvelisa amacandelo aqinileyo nawomngxuma onobunzima becandelo, kunye namacandelo eendawo eziguqukayo kunye notshintsho oluthe ngcembe kunye notshintsho oluthe chu ngakwicala lobude becandelo lemveliso.

Uluhlu lwemilinganiselo lubanzi kakhulu, ukusuka kwiityhubhu ezinkulu kakhulu kunye neeprofayili ezinamacandelo enobubanzi besangqa sangaphandle se-500-1000mm ukuya kuncinci kakhulu ukuchithwa ngokuchanekileyo enamacandelo alingana nemicinga yematshisi.