Iminyaka engama-20 yamava ekubambeni okubandayo / ukuzoba / ukushisa ishishini elenza ialuminium ingxubevange, egxile ekufeni kokufa kunye nokubetha / ukuzoba / ukubumba / ukuvelisa i-CNC kunye nokulungiswa kweemveliso zealuminium, ukungunda kwealuminium.

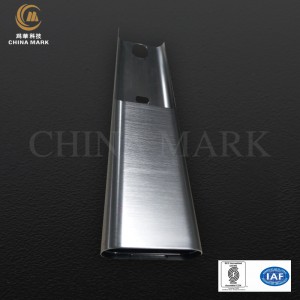

I-Aluminium extrusion yesayensi yaseTshayina kunye netekhnoloji, esetyenziswa ngokubanzi, iindidi ezipheleleyo, umgangatho ophezulu, inkonzo yokuqala, ifuthe le-aluminium ye-extrusion inokwenziwa ngokwezifiso ngokweemfuno ezahlukeneyo, wamkelekile ukudibana;

Inkqubo yealuminium extrusion

Inkqubo yokusebenza:

1. Fudumeza isilinda se-ingot ukuya kuma-380 ℃ - 420 ℃ ngohlobo lwegradient ye-100 ℃ / 1 yeyure.

2. Ngokwephepha lesicwangciso sokusebenza, khetha inani elifanelekileyo le-bar ye-aluminium efanelekileyo yokufudumeza iziko ukuya kwi-480 ℃-520 ℃, iiprofayili ezizodwa zeshishini ngokwenkqubo yobushushu echaziweyo.

3. Ngokwesicwangciso sokusebenza, khetha ukungunda ngokungqinelana nesicwangciso, usitshise ukuya kuthi ga kwi-460 ℃ - 500 ℃, kwaye usigcine sishushu kangangeyure ezi-2 ukuya kwezi-4.

4. Qalisa i-extruder yokupholisa iimoto-yeoyile yemoto.

5. Ngokomyalelo omnye wesicwangciso, khetha umqamelo okhethekileyo wokubumba oza kufakwa kwisiseko sokubumba, kwaye utshixe isiseko sokubumba kwindawo yokukhutshwa.

6. Tshixa igubu lokubamba uze uphakamise ibha ye-aluminium eshushu ubume kwindawo ehambelana nayo ye-gallbladder yezinto ngokusebenzisa i-rack rack.

7. I-Master cylinder phambili extrusion

8. Isantya sokuqala sokucinezela kufuneka sicothe, kwaye isantya esiphakathi kufuneka silungelelaniswe ngokomgangatho womgangatho weprofayile kwindawo ephumayo.

9. Rekhoda inombolo yokubumba, inombolo yealuminiyam, uxinzelelo lwesilinda kunye nokukhupha isantya ngokweenkcukacha kwirekhodi yoqobo.

Ii. Inkqubo efunekayo

1. Iqondo lobushushu lokufudumeza intonga yealuminium kumatshini yile: Ukufa okuthe tyaba: 500 ℃ - 520 ℃ b. ukwahlula kufa: 480 ℃ - 500 ℃ c. izixhobo ezizodwa mveliso zenziwa ngokweemfuno ezizodwa inkqubo.

2. Inkqubo yokufudumeza umngundo: a. Iflethi ifile: 460 ℃ - 480 ℃ b. Ukwahlulahlulafa: 460 ℃ - 500 ℃

3.Ukuseta ubushushu betyhubhu: 380 ℃-420

4.Izinto ezikhutshiweyo kufuneka zibenomphezulu ogudileyo, akukho luvo lwesandla sokuqhelaniswa nobude obude, okucoliweyo kunye nokutya okuziinkozo, akukho bhanti likhanyayo, umgca omnyama, umsantsa wenqwelomoya phakathi kweenqwelomoya zeYin kunye neYang, ukuphambuka kwe-Angle, kunye ne-Angle yokusika kufuneka ibe phezulu inqanaba lokuchaneka ngokomgangatho kazwelonke.

5.Uxinzelelo lwe-extrusion: ≤200㎏ / cm2

Uxinzelelo lwe-6 gall lock 120㎏ / cm2 - 150㎏ / cm2.

7. Ubushushu beoyile hydraulic raulic45 ℃

8. Isantya sokuphuma kwiprofayili silawulwa ngokubanzi kwi: 5 m / min -30 m / min

10. Yonke into ekhutshwa ngaphandle kweentonga ezingama-80 -100, kufuneka zisebenzise umqamelo okhethekileyo wokucoca inyongo.

Ntathu. Imiba efuna ingqalelo

1. Ngexesha lokukhutshwa, ukuba idiski iplagiwe, ixesha lokufa aliyi kudlula kwimizuzwana emi-5.

2. Xa ufaka ukungunda, nikela ingqalelo kukhuseleko kwaye unqande isikrufu ekutyibilikeni size saphule unyawo.

3. Xa uphuma, kuthintelwe ngokungqongqo ukukroba ngokuthe ngqo kwindawo yokuphuma.

4. Phambi kokufaka idesika, kufuneka kujongwe indawo ekubekwe kuyo iziko kwaye kufuneka i-extrusion rod ihambelane. Umatshini wokuvavanya umthwalo ongafakwanga mthwalo kufuneka usebenze kube kanye ngaphambi kokuqala umatshini.

5. Nokuba ubushushu beentonga zokulinganisa, ukungunda kunye ne-ingot barrel kuyahlangabezana neemfuno.

6.3 - jonga umgangatho weentonga ezi-5 kube kanye.

Jonga ubushushu beoyile rhoqo.

8. Nokuba ibar yealuminium nganye iphawulwe ngenani lomlilo kunye nenombolo yebhaso.