I-aluminium eyandisiweyo-ikhangela itekhnoloji ye-weihua [abathengisi besiko be-aluminium yesiko] ngaphezulu kweminyaka eli-10 yamava okwenziwa kwemveliso. Ubuncinci be-aluminium extrusion, igolide ye-aluminium extrusion, inkqubo ephezulu yokuphelisa, abavelisi abathengisa ngokuthe ngqo, umgangatho wemveliso, wamkelekile ukubonisana!

Yintoni inkqubo yokuqhubekeka kwesinyithi sefowuni yealuminium efakwe?

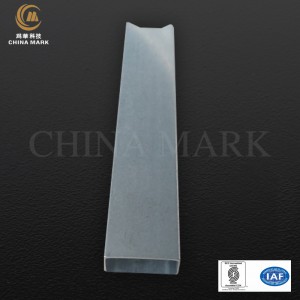

1. IAluminiyam extrusion

Isinyathelo sokuqala ukusika nokukhupha i-aluminium ye-cylindrical, inkqubo eyaziwa ngokuba yi-aluminium extrusion, eyenza i-aluminium ekhutshiwe ibe yiphepha le-10mm ekulula ukulenza kunye nokuxinana kwaye kube nzima. Lo ngumsebenzi ofuna ukusebenza kwe-extrusion mold.

2. I-DDG

Isixhobo somatshini we-CNC (ukubola okukhawulezileyo kunye neziko lokucofa) kwakusetyenziselwa ukugaya ngokuchanekileyo iphepha lealuminium kumthamo owakheke-ntathu we-152.2 × 86.1 × 10mm nge-DDG ukulungiselela ukugqitywa kwe-CNC elandelayo.Le nkqubo iqala ngokusetyenziswa kwezixhobo ze-carbide Isixhobo seCNC carbide

3. Ukurhabaxa kokurhabaxa kwangaphakathi

Ukuze kube lula machining CNC, umzimba yesinyithi zixinaniswe yi eligaqa eludongeni.Rough yokugaya kwisisu ngaphakathi, kwisisu ngaphakathi, kwakunye ikholam yokuma edityaniswe nokulungiswa lwemidlalo, nto leyo ibalulekileyo ikhonkco processing elandelayo.

4. wokugaya eriyali

Kwiifowuni zonke zesinyithi, eyona ngxaki inzima ukuyisombulula yingxaki yomqondiso, eyabangelwa sisiginali esibi esabangelwa sisakhelo sesinyithi xa i-iPhone 4 yayisungulwa okokuqala. IAluminiyam ikwathintela (yenze buthathaka) isignali yefowuni yerediyo, ke kufuneka ibekwe ukuze umqondiso ube nendlela yokuphuma nokuphuma, ke ngoko, ukugaya i-eriyali slot lelona libaluleke kakhulu, elona nyathelo linzima, indawo yokubamba ye-eriyali kufuneka igaye ngokulinganayo, kwaye igcine iindawo zonxibelelwano eziyimfuneko ukuqinisekisa ukomelela kunye nengqibelelo yegobolondo yesinyithi.

5. T ukuphatha

Emva kokugaya i-eriyali, i "T unyango" isetyenziselwa ukunyanga ialuminium kumphezulu onokudityaniswa neeplastikhi zobunjineli. Umzimba wesinyithi kufuneka ubekwe kwiarhente ekhethekileyo yemichiza, efana nolwelo T, ukwenza i-nanoscale (1 nanometer = 10 ^ -9 yeemitha) imingxunya kumphezulu wealuminium, ukulungiselela inaliti elandelayo yenanoscale.

6.NMT nano ziphene yokubumba

Inkqubo "yokubumba ngenaliti" ivumela inkqubo yokubumba yenaliti ye-NMT ukuba iphunyezwe ngenxa yomzimba wensimbi ophathwe yi-T.NMT nano ngenaliti yokubumba kukucudisa iplastiki ekhethekileyo phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu kwizinto zentsimbi emva konyango lwe-T, ke ukuba iplastiki kunye nomphezulu wentsimbi we-nanoscale imingxunya emincinci idityaniswe ngokuqinileyo, ukuze kufezekiswe injongo yokuqinisa i-eriyali.

7. Gqiba umhlaba wokugaya wecambered

Kwiifowuni zonke zesinyithi, ukongeza kwi-eriyali yomqondiso, kukho ukubunjwa kwe-3D yomzimba wentsimbi, eyenzeka njengeyona nkqubo ichitha ixesha, ithatha ngaphezulu kwemizuzwana eyi-1 000.

8. Gqiba icala lokusila

Abahlobo abanononophelo banokuqaphela ukuba umphezulu we-3D onqabileyo womzimba wentsimbi ubugaywa yi-CNC, kodwa kusekho isangqa sokuncitshiswa okungqonge umda, esidinga ukugaywa ngokuchanekileyo kwecala, emva koko ungabona iprototype yesinyithi. iqokobhe.

9. ipolishi

Ngaphambi kokusetyenziswa kwamanqanaba aphezulu asezingeni eliphezulu ngokuchanekileyo kwezixhobo zomatshini we-CNC, kodwa unokufikelela kuphela kugqitywa kweklasi ye-A1 ~ A2, ukufezekisa iimfuno zokuqhubekeka emva koko, kufuneka icocwe kugqitywe iklasi ye-A0, inokuba sisiphumo sesipili.

10. Isanti yentlabathi

Nangona kunjalo, yonke le fowuni yentsimbi ayinasiphumo sigcweleyo, kodwa iveza umphezulu weqabaka. Oku kufuna inkqubo "yokuthambisa isanti" ukunyanga umphezulu wesinyithi kwisiphumo sokukhenkceza.

11. Inode enye

I-Aluminium alloy izinzile, ukuze ingaphazanyiswa zizinto zangaphandle ezinjengokubila, kufuneka yenziwe anodized.Yinkqubo yokufaka umbala kwifowuni, etshintsha umbala wealuminiyam ube yigolide nge-anodizing.Kunzima kakhulu ukulawula Inkqubo yokudaya i-aluminium alloy, umbala okwahlukileyo, amabala aya kuvela ukuba ulawulo alulungile, oluya kunciphisa isivuno.

12. Ukuqaqambisa unyango

Uyilo lokusika olucekeceke lufuna ukusika iikona kusetyenziswa elona banga liphezulu koomatshini be-CNC be-ultra-high, inkqubo ekwabizwa ngokuba kukugrumba okanye ukuqaqambisa.

13. Gqibezela ukusila ingaphakathi

Emva kwamanyathelo ali-12 okuqhubekeka, iqokobhe lesinyithi sele liqalile ukubona inkangeleko, emva koko iya kusetyenziswa ukubamba ikholamu yokubeka indawo kunye nezinye izinto ezigqithisileyo zisuswe, vumela iqokobhe lesinyithi ngaphakathi licoceke ngokupheleleyo.

14. I-anode yesibini

Iqokobhe, eliqhutywe yi-CNC, lifuna unyango lwesibini lwe-anodic ukuze ludibanise umphezulu kwaye lenze ifilimu eshinyeneyo kunye ne-oxide enzima, iyenze inxibe ngakumbi kwaye ingabi lula ukuyichaphazela.

Ukugaya isuntswana lokuqhuba

Emva kokuba iodidid oxidation yealuminium ingxubevange isiphumo sokuqhuba iya kuba mbi, ke kuyafuneka ukuba ususe ifilimu ye-anodic oxidation yasekhaya, isinyithi esivelisiweyo ukuze ufumane isiphumo esihle sokumisa, ikwafuneka ukuba ugqithe kumatshini wokugaya we-CNC.

16.Hot unyibilike nut

Okokugqibela, le ndibano yendibano ifakwe ngaphakathi kwiplastikhi egqityiweyo ngengalo yerobhothi ukuqinisekisa indibano yexesha elizayo yeefowuni zealuminium.