Inkqubo yealuminium extrusion

Inkqubo ye-aluminium alloy extrusion empeleni iqala ngoyilo lwemveliso, kuba uyilo lwemveliso lusekwe kwiimfuno zokusetyenziswa ezinikiweyo, ezimisela uninzi lweeparameter zokugqibela zemveliso.Ukusebenza kwemveliso yokusebenza ngomatshini, ukusebenza komphezulu wonyango kunye nokusetyenziswa kweemfuno zokusingqongileyo , ezi ndawo kunye neemfuno zichonga ukhetho lwealuminium ekhutshiweyo.

Nangona kunjalo, iipropathi zealuminiyam ekhutshiweyo zichongiwe yimilo yoyilo lwemveliso.Ubume bemveliso bumisela ubume bokufa kwe-extrusion.

Nje ukuba isonjululwe ingxaki yoyilo, inkqubo yokuphamba isebenzayo iqala i-extrusion cast kwi-aluminium rod, i-aluminium yokuphosa intonga kufuneka ifudunyezwe ngaphambi kokuba i-extrusion ithambe, ukufudumeza intonga elungileyo ye-aluminium yokufaka i-sheng ingot ifakwa emgqonyeni we-extruder ngaphakathi, emva koko iphakame I-hydraulic cylinder yokunyusa intonga ye-extrusion, isiphelo sangaphambili sentonga ye-extrusion ine-pad yoxinzelelo, eshushu evuthayo i-aluminium alloy kwindawo yedummy phantsi koxinzelelo olomeleleyo oluvela kumbumbulu ngokuchanekileyo ekubumbeni i-extrusion molding.

Nantso ke into yokubumba: imilo yemveliso efunekayo kwimveliso.

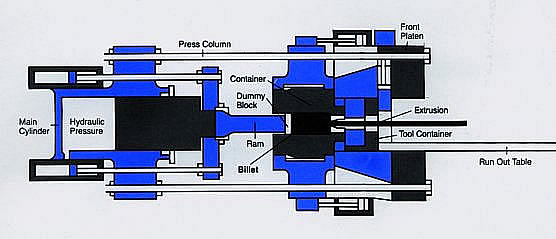

Lo mfanekiso: ngumzobo oqhelekileyo we-hydraulic extruder schematic diagram

Isalathiso sokukhupha sishiye ekunene

Le yinkcazo elula yokusetyenziswa ngokuthe ngqo ngokuthe ngqo namhlanje. Ukukhutshwa ngokungangqalanga yinkqubo efanayo, kodwa kukho umahluko obaluleke kakhulu.

Kwinkqubo engangqalanga ye-extrusion.I-die ifakwe kwi-bar extrusion bar, ukuze i-die icinezelwe kwindawo ye-aluminium engenakususwa engenanto, inyanzelisa i-aluminium alloy ukuba ikhuphe iye kwi-bar extrusion bar nge-die.

Ngapha koko, inkqubo yokukhutshwa iyafana nokucofa i-toothpaste. Xa uxinzelelo lusetyenziswa kwisiphelo esivaliweyo samazinyo, intlama yamazinyo ye-cylindrical iyakhanywa ngokuvula okujikelezayo.

Ukuba ukuvulwa kuthe tyaba, intlama yamazinyo efinjiweyo iphuma njengebhanti.

Ewe kunjalo, iimilo ezintsonkothileyo zinokukhanywa xa kuvulwa imilo efanayo, umzekelo, abenzi bekhekhe basebenzisa iityhubhu ezimile ngokukodwa ukukhama i-ayisi khrim ukwenza zonke iintlobo zeefrills.

Ngelixa ungenako ukwenza iimveliso ezininzi eziluncedo ngentlama yamazinyo okanye i-ayisi khrim, awunakucofa i-aluminium kwiityhubhu ngeminwe yakho.

Kodwa ungasebenzisa umshicileli onamandla we-hydraulic ukukhupha i-aluminium kwisimo esithile sokubumba ukuvelisa iintlobo ezahlukeneyo zeemveliso ezisebenzisekayo phantse nayiphi na imilo.

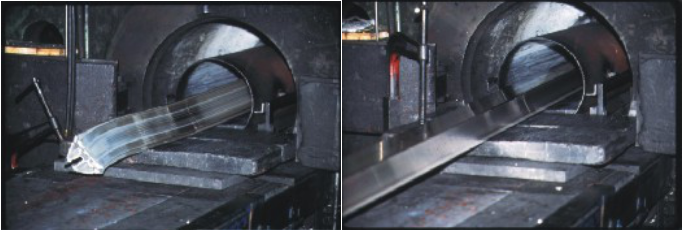

Inani elingezantsi (ngasekhohlo) libonisa icandelo lokuqala lesikhuphisi ekuqaleni kokukhutshwa. (kunene)

Ibha

Ibha ye-aluminium ayinanto kwinkqubo yokukhutshwa. Ibha ye-aluminium esetyenziselwa ukukhupha inokuba yomelele okanye ingenamngxunya, ihlala i-cylindrical, kwaye ubude bayo bugqitywe yityhubhu ye-extrusion.

Iintonga zeAluminiyam zihlala zenziwe ngokulahla, okanye ngokwenza okanye ngomgubo wokwenza umgubo ngesiqhelo kwenziwa ngokucheba imivalo yealuminium ene-alloy efanelekileyo.

I-Aluminium alloys zihlala zenziwe ngaphezulu kwesinye sentsimbi. Iialloys ezenziwe ngealuminium zenziwe ngomkhondo (zihlala zingabikho ngaphezulu kwe-5%) yezinto (ezinje ngobhedu, i-magnesium, i-silicon, i-manganese, okanye i-zinc) eziphucula iipropathi ze-aluminium emsulwa kwaye ichaphazela inkqubo yokukhutshwa.

Ubude beentonga zealuminiyam buyahluka ukusuka kumenzi ukuya kumenzi, ogqitywe bubude obufunekayo bokugqibela, umlinganiso we-extrusion, ubude bokukhutshwa kunye nesibonelelo se-extrusion.

Ubude obuqhelekileyo ngokubanzi bususela kwii-intshi ezingama-26 (660mm) ukuya kwii-intshi ezingama-72 (1830mm). Ngaphandle iidayimitha ziqala kwii-intshi ezi-3 (76mm) ukuya kwii-intshi ezingama-33 (838mm), ii-intshi ezi-6 (155 mm) ukuya kwii-intshi ezi-9 (228 mm).

Inkqubo yokukhutshwa ngokuthe ngqo

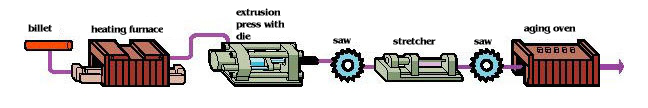

[billet] [ukufudumeza indawo] [iprinta ye-extrusion ene-die] isarha [istrecher] [ukuguga overn]

Umzobo ubonakalisa amanyathelo asisiseko okukhupha ibar yealuminium

Xa ubume bokugqibela bemveliso bugqityiwe, kukhethwe i-aluminium efanelekileyo, ukugqitywa kwemveliso yokufakwayo kugqityiwe, kwaye ukulungiswa kwenkqubo yokwenyani kugqityiwe.

Emva koko preheat ibha yealuminium kunye nesixhobo sokukhupha. Ngexesha lenkqubo yokukhutshwa, ibha yealuminiyam iqinile, kodwa ithambile eziko.

Indawo yokunyibilika yealuminium ingxubevange emalunga ne-660 ℃ .Ukufudumeza okuqhelekileyo kwenkqubo ye-extrusion ngokubanzi kukhulu kune-375 ℃ kwaye kungaphakama kangange-500 ℃, kuxhomekeke kwimeko ye-extrusion yesinyithi.

Inkqubo yokwenyani ye-extrusion iqala xa intonga ye-extrusion iqala ukufaka uxinzelelo kwintonga ye-aluminium kwi-ingot.

Oomatshini bokushicilela abahlukeneyo be-hydraulic bayilelwe ukucudisa naphina ukusuka kwiitoni ezili-100 ukuya kwiitoni ezingama-15,000. Olu xinzelelo lwe-extrusion lumisela ubungakanani be-extrusion eveliswa ngumatshini we-extrusion.

Ukucaciswa kwemveliso eyandisiweyo kubonisiwe ngokobuninzi becandelo lobunqamlezo bemveliso, ngamanye amaxesha kukwenziwa ngobubanzi obujikeleze imveliso.

Xa i-extrusion sele iqalile, i-bar ye-aluminium ixhomekeke kumandla okusabela ekubumbeni kwaye iba mfutshane kwaye iyatyeba, kude kube kukwandiswa kwebar yealuminiyam kuthintelwe udonga lwe-ingot yomgqomo;

Ke, njengoko uxinzelelo luqhubeka ukwanda, isinyithi esithambileyo (esisomeleleyo) asinandawo yokubaleka kwaye siqala ukukhanywa siphume kumngxunya wokubumba wokubumba siye kwelinye icala lobumba, ukwenza iprofayili.

Phantse i-10% yentonga ye-aluminium (kubandakanya isikhumba se-aluminium yentonga) ishiyeke emgqonyeni we-ingot, imveliso ye-extrusion iyanqunyulwa kwisikhunta, kwaye isinyithi eseleyo emgqomeni we-ingot iyacocwa iphinde iphinde iphinde isetyenziswe. Inkqubo elandelayo kukuba imveliso eshushu ye-extrusion iyacinywa, yenziwe ngomatshini kwaye indala.

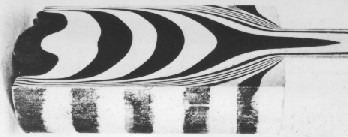

Xa i-aluminium evuthayo ikhutshwa ngaphandle kwesikhunta ngokusebenzisa isilinda se-ingot, isinyithi embindini webar aluminium sihamba ngokukhawuleza kunomphetho.Njengoko umgca omnyama kulo mzekeliso ubonisa, isinyithi esijikeleze imiphetho sishiywa ngasemva ukuze siphinde senziwe kwakhona intsalela.

Izinga lokukhutshelwa ngaphandle lixhomekeke kwisinyibilikisi esicudisiweyo kunye nokumila komngxunya wokufa. Ukusebenzisa i-alloy enzima ukucoca izinto eziyinkimbinkimbi kunokucotha njenge-1-2 yeenyawo ngomzuzu.Ngama-alloys athambileyo, iimilo ezilula zinokufakwa kwi-180 yeenyawo ngomzuzu okanye ngaphezulu.

Ubude bemveliso ye-extrusion buxhomekeke kwibar yealuminium kunye nomngxunya wokuphuma komngundo. Ukukhutshwa okuqhubekayo kunokuvelisa imveliso ukuya kuthi ga kwi-200 yeenyawo ubude.Ukubumba kwakutshanje, xa imveliso ekhutshiweyo ishiya i-extruder ibekwe kwisilayidi (esilingana nebhanti yokuhambisa);

Ngokwe-alloy eyahlukeneyo, ukukhutshwa kwimowudi yokupholisa imveliso: yahlulahlulwe kukupholisa kwendalo, umoya okanye ukupholisa amanzi kodwa kucima.Leli linyathelo eliphambili lokuqinisekisa ukusebenza kwe-metallographic yemveliso emva kokuguga. ibhedi ebandayo.

Yolula

Emva kokucima (ukupholisa), imveliso ekhutshiweyo ithe nkqo kwaye yolulwa ngesawuli okanye i-straightener (ukolulwa kukwahlelwa njengokusebenza okubandayo emva kwe-extrusion) Ekugqibeleni, imveliso igqithiselwa kumatshini wokusaha ngesixhobo esidlulisayo.

Ukuseka

Ukugqitywa kwemveliso egqityiweyo kukusawa kwemveliso kubude obuthile beentengiso.Iisarha zesetyhula zezona zisetyenziswa kakhulu namhlanje, njengeesarha zengalo ezijikelezayo ezisika iziqwenga ezinde zento ethe nkqo.

Kukho iisarha ezisikiweyo ukusuka phezulu kwiprofayile (njengombane wombane) kunye netafile yesarha eluncedo, itafile yesarha ine-disc blade ukusuka ezantsi ukuya kusika imveliso, emva koko isarha ibuyele ezantsi yetafile yomjikelo olandelayo.

Isarha egqityiweyo egqityiweyo ziisentimitha ezili-16 ukuya kwezi-20 ububanzi kwaye inamazinyo e-carbide angaphezu kwe-100.

Lo matshini sawing yokuzibamba ifakelwe inkqubo ehambisa igrisi kwi-sawtooth ukuqinisekisa ukusebenza kakuhle kweesarha kunye nomphezulu wesarha.

Umatshini wokushicilela ozenzekelayo ubamba amacandelo endaweni yokusaha kwaye inkunkuma yokusaha iqokelelwa ukuze iphinde isetyenziswe.

Ukwaluphala:

Ezinye iimveliso ezikhutshiweyo zifuna ukwaluphala ukuze zifumane amandla amakhulu, ke oko kukwabizwa ngokuba kukwaluphala.Ukuguga kwendalo kwenziwa kwigumbi lobushushu.Ukuguga okwenziweyo kwenziwa kwiziko lokuguga.Ngokobuchwephesha, kubizwa ngokuba yimvula enzulu yokunyanga ubushushu.

Xa iprofayili ikhutshiwe kwi-extruder, iprofayili iyaqina, kodwa kungekudala iyaqina xa ipholile okanye icinyiwe (nokuba ipholile umoya okanye ipholile ngamanzi).

I-alloys ye-aluminium enganyangekiyo (efana ne-aluminium alloys kunye ne-magnesium okanye i-manganese) iyomelezwa ngokuguga kwendalo kunye nokusebenza okubandayo. Ukushisa kwe-alloyum alloy (njenge-aluminium alloy kunye nobhedu, i-zinc, i-magnesium + yesilicon) inokufumana amandla angcono kunye nobunzima Ngokuchaphazela unyango lobushushu lwesakhiwo se-alloy metalgraphic.

Ukongeza, ukwaluphala kukwenza amasuntswana esigaba esomeleziweyo ahlukaniswe ngokulinganayo ukuze afumane amandla aphezulu esivuno, ubunzima kunye nokomelela kwe-alloy ekhethekileyo.

Bales

Nokuba ukuguga kwesithando somlilo okanye ubushushu begumbi, emva kokuguga okugcweleyo, iprofayili igqithiselwa kunyango lomphezulu okanye kumasifundisane wokuqhubekeka nzulu okanye iibhali ezilungele ukuthunyelwa kumthengi.

Abantu bayabuza

Ixesha Post: Mar-20-2020